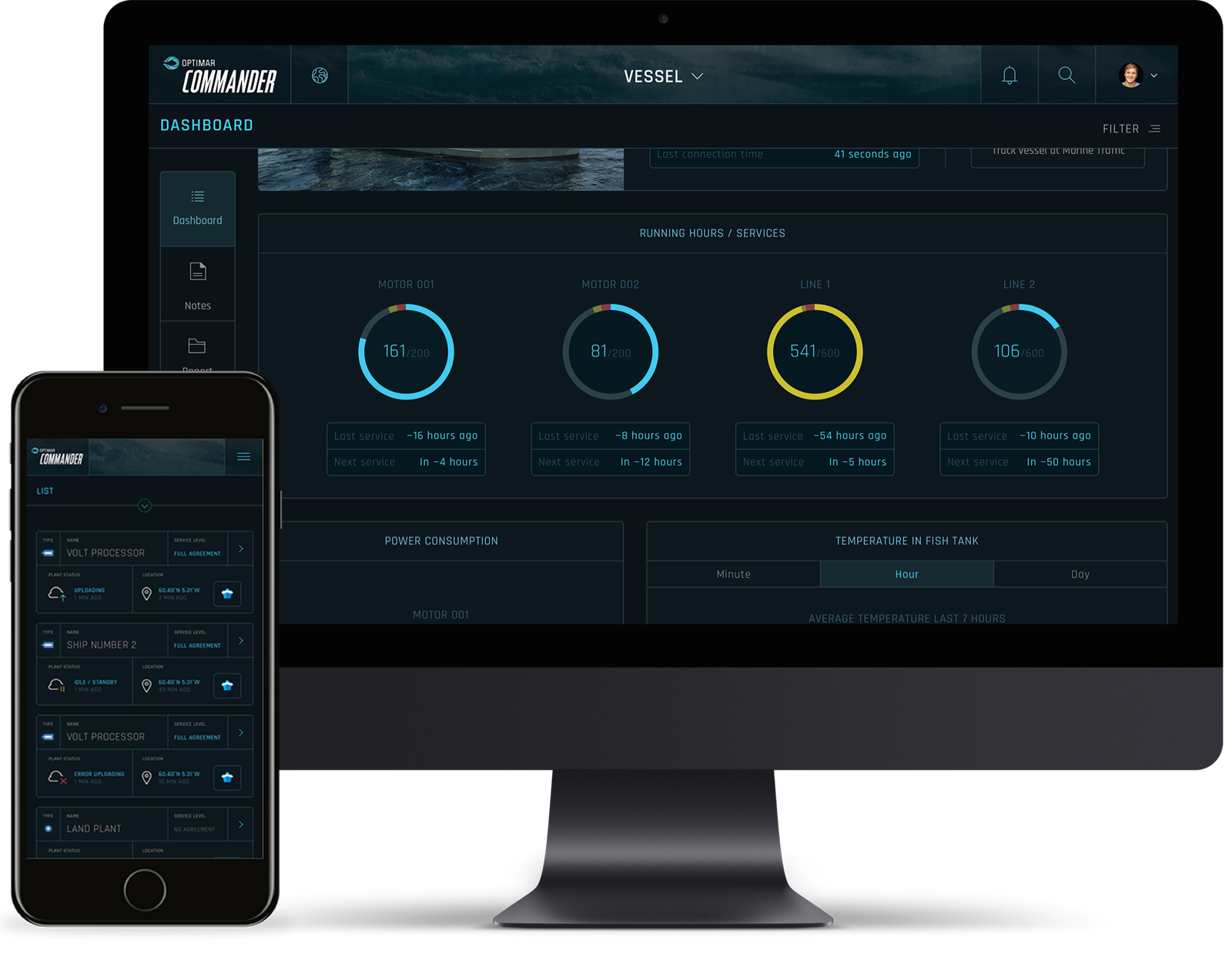

Embrace the future with predictive data

Optimar Commander is a digital platform for gathering and sorting information from every machine in your factory, including third-party equipment. The live data helps you understand the bigger picture and equips you with the insight you need to make decisions with certainty. Get ready for predictive maintenance, increased efficiency, and higher product quality.

A complete overview

The best decisions, both real-time and predictive, are made based on accurate information. Optimar Commander continuously captures data to offer a live overview of everything going on. In addition, the platform provides notifications and sounds the alarm if any of your equipment is not working properly. Our industry is increasingly automated and technically advanced – that demands a complete overview.

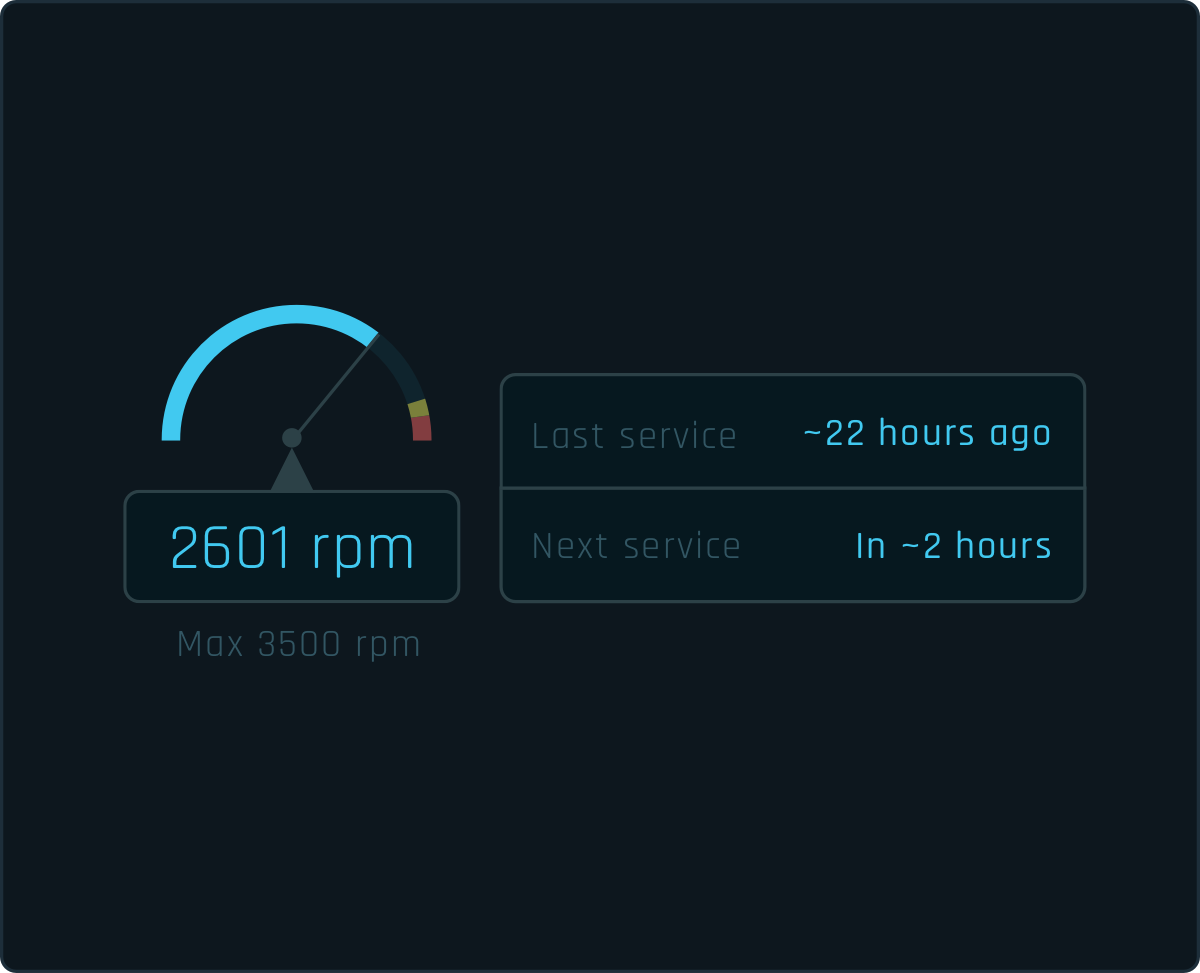

Running time

The live data feed provides detailed information about the equipment and its running time, alerting operators of errors or stops and predict when machines need maintenance. This makes it easier to plan ahead and reduce downtime.

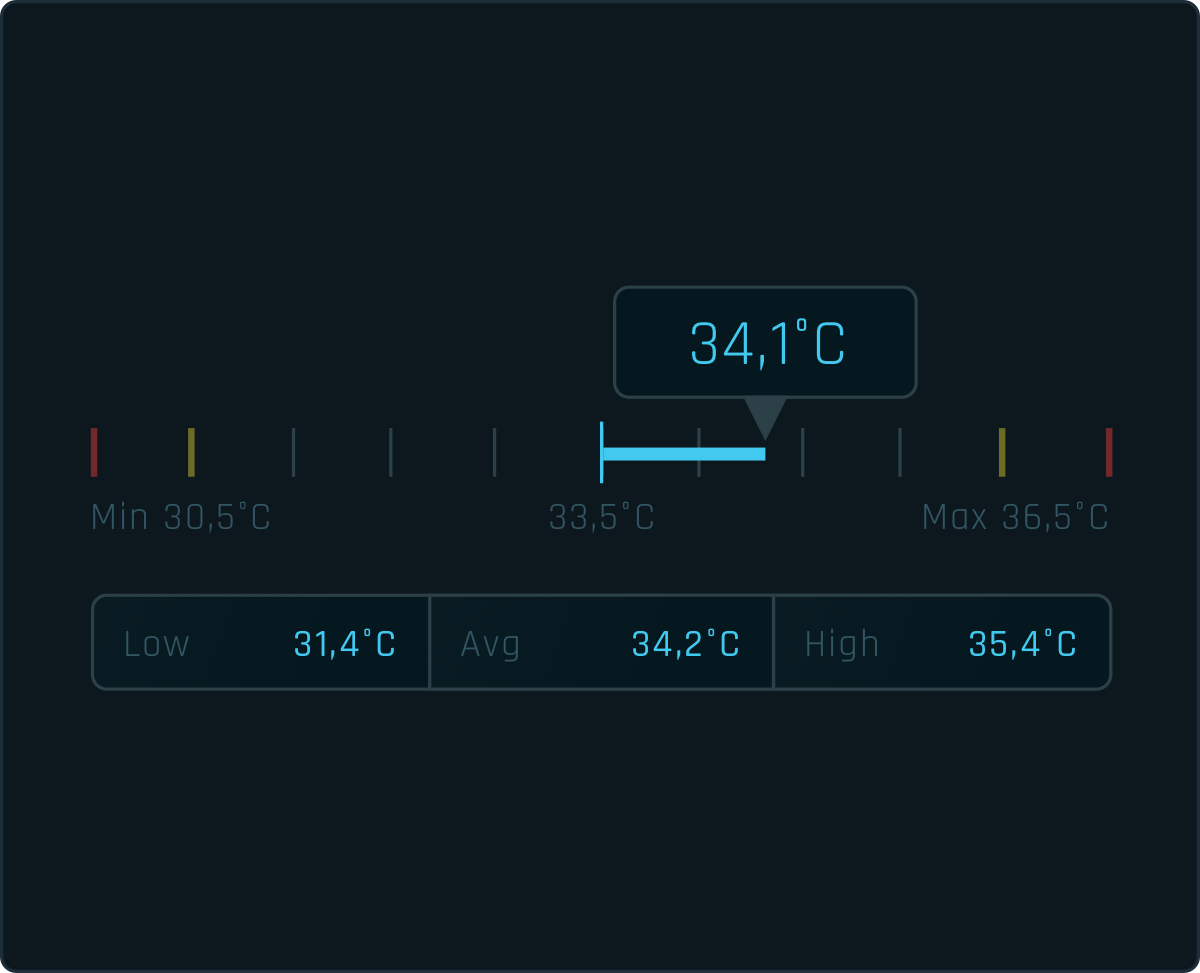

Temperature

The system calculates the ideal water temperature and shows your real-time temperature, as well as a detailed history. This will indicate if your average temperature is within the correct parameters or if you need to make adjustment.

RPM

Optimar Commander links all components of the factory together and provides accurate RPM so you can ensure your factory is running efficiently without any errors.

Commander Web

Commander Onsite

Commander Web runs in the cloud and can be opened in browsers such as Chrome or Explorer. With a digital copy of your factory, even those outside the factory floor can get full insight in the dashboards.

● View live data on quality, quantity, amount or other relevant information.

● Receive official documentation for your factory. Such as electrical drawings, data sheets and manuals.

● 24/7 support with the possibility to submit service request and communicate on ongoing cases with Optimar across shifts

● Group information such as manually registered data and control system data together towards specific operations in your facility. Fully customizable towards your operation.

● Generate a fully customizable PDF-report based on the specific operations.

● Tailor made control pictures for users with the most important information for users, enabling full control at a glance on the screen.

● Control pictures per machine or system with all available information, for detailed control or insight.

● Get the opportunity to comment on choices, changes or observations through the Digital Logbook.

● Make troubleshooting easier with access to information relative to each other in the same timeline.

● All alarms from all systems in one platform.

● Get context to your data. The platform puts data from your facility up against specific operations. That way we can group the data and generate reports on each operation.

Contact

Optimar

We’re happy to give you a demonstration of our digital platform, so don’t hesitate to contact us.