About Aquaculture

State of the art equipment

Optimar has extensive experience in delivering products and solutions for aquaculture and fisheries worldwide.

Our expertise in the field has positioned us as a preferred partner within design and engineering, as well as service. A minimum level of stress for the fish equals a high quality product at the end of the process.

Our equipment for industrial processing of fish involves no chemicals and gentle handling in high capacity systems – both standardized and custom made. Our products span from sea lice removal and robot palletizing systems to electric stunning machines and mort handling.

Design

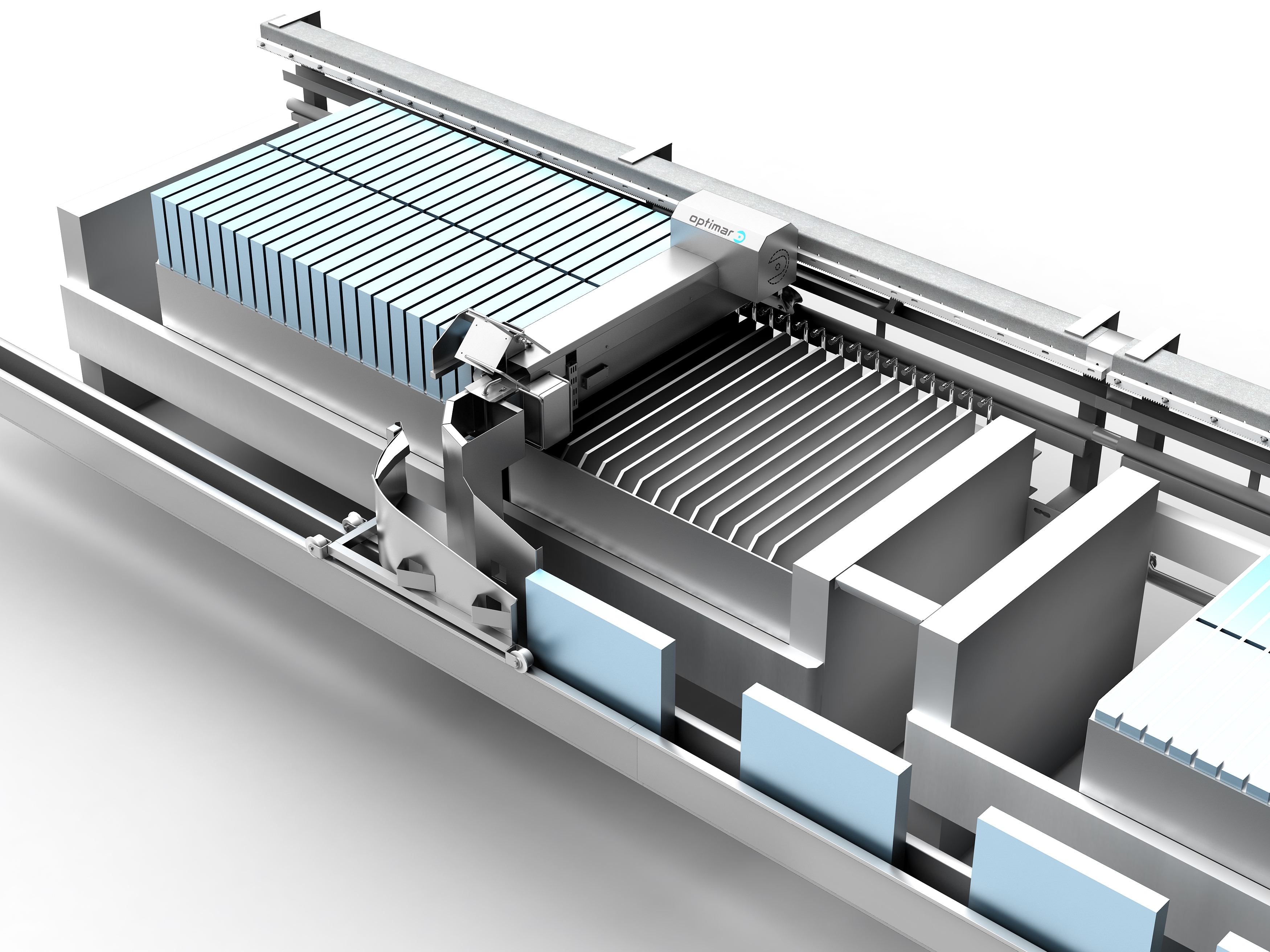

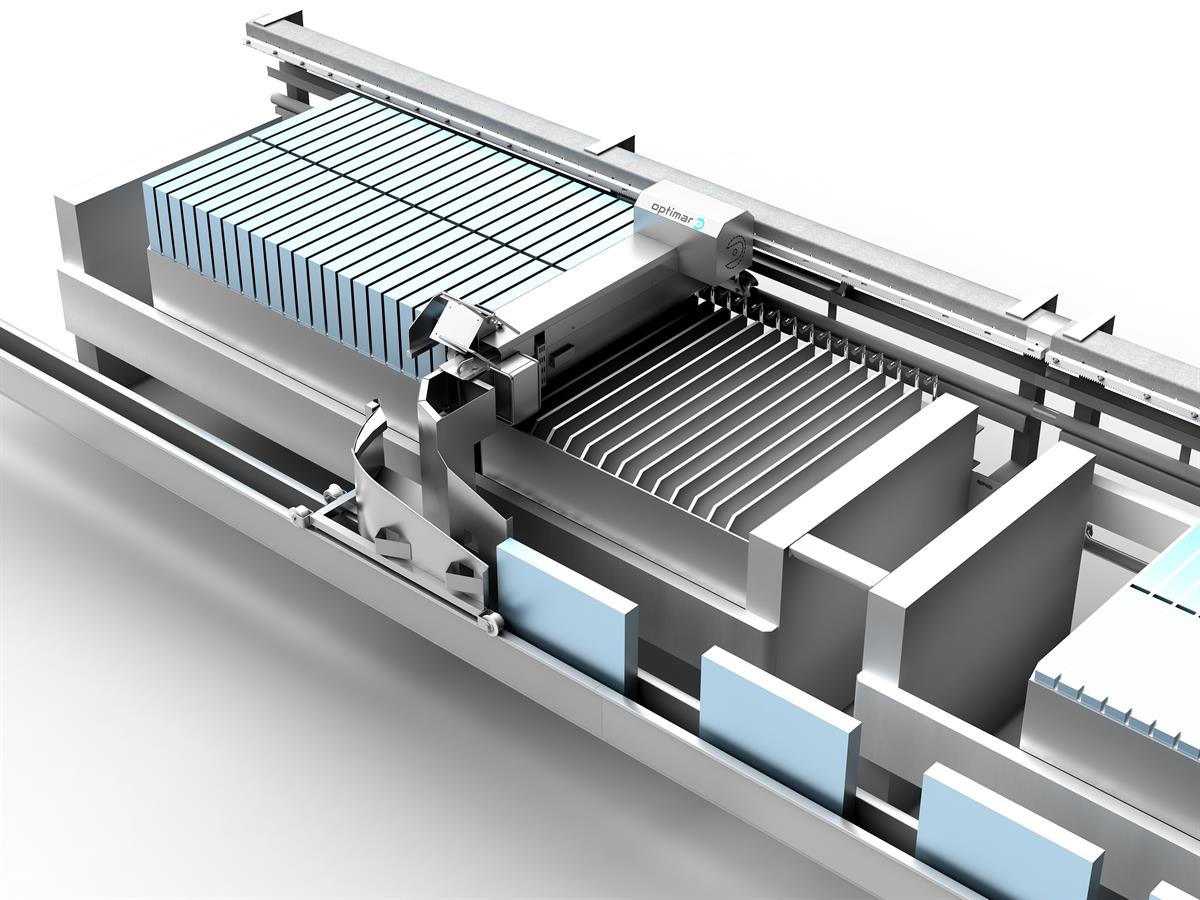

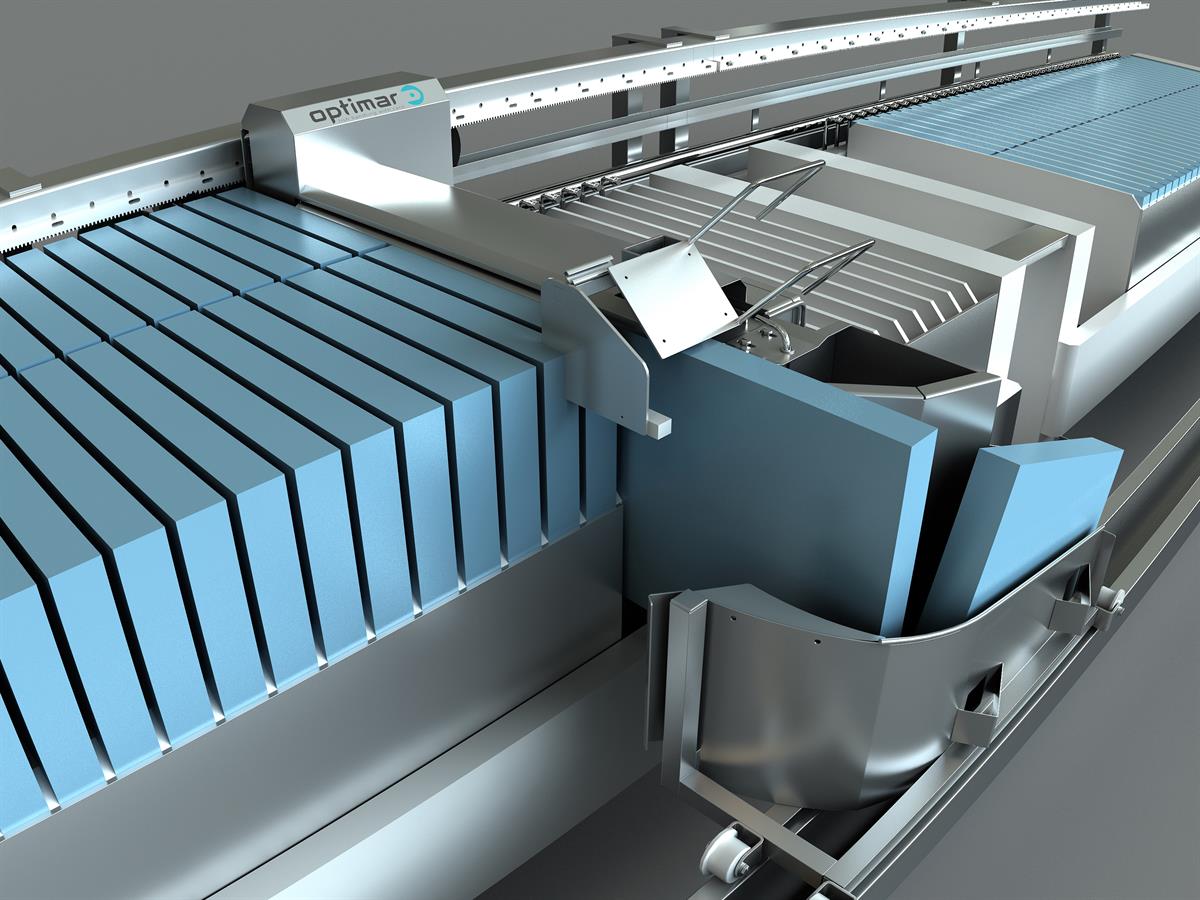

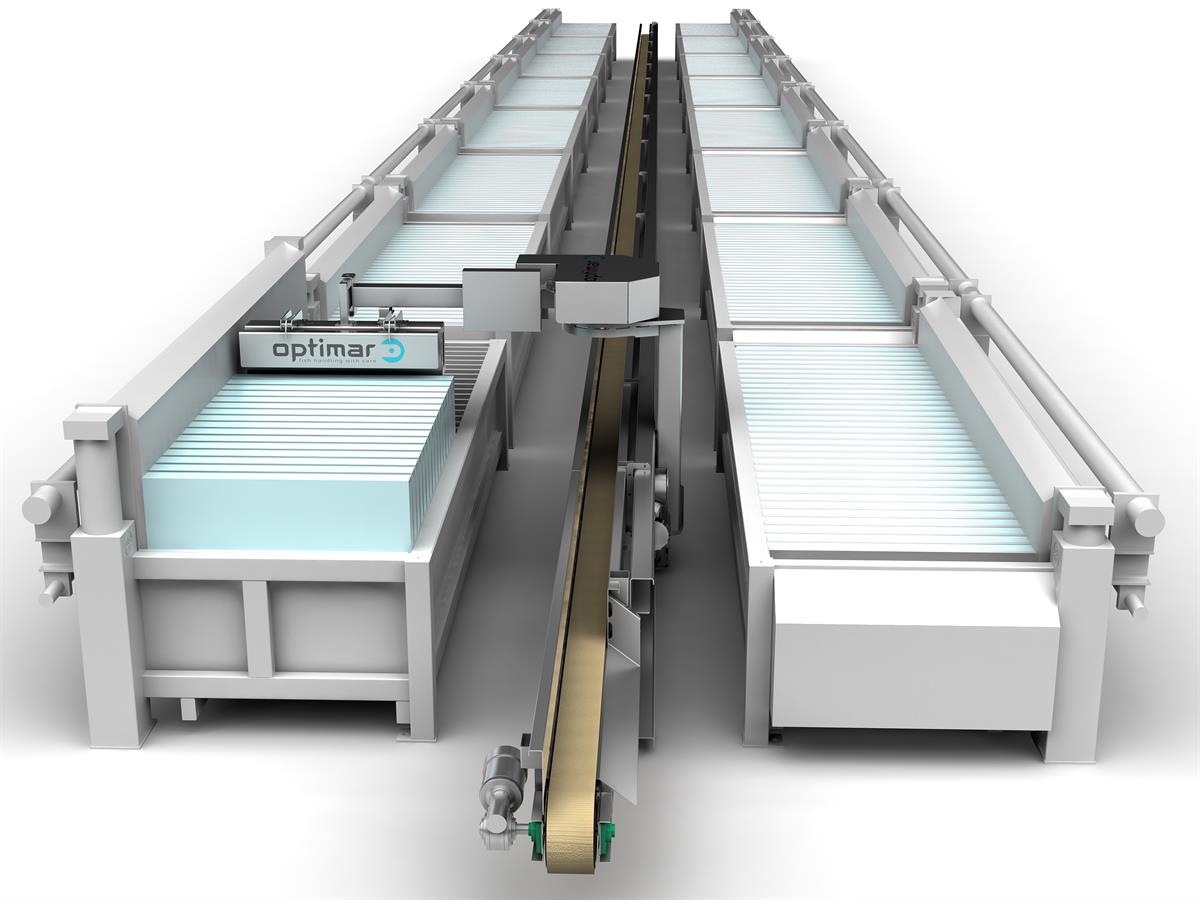

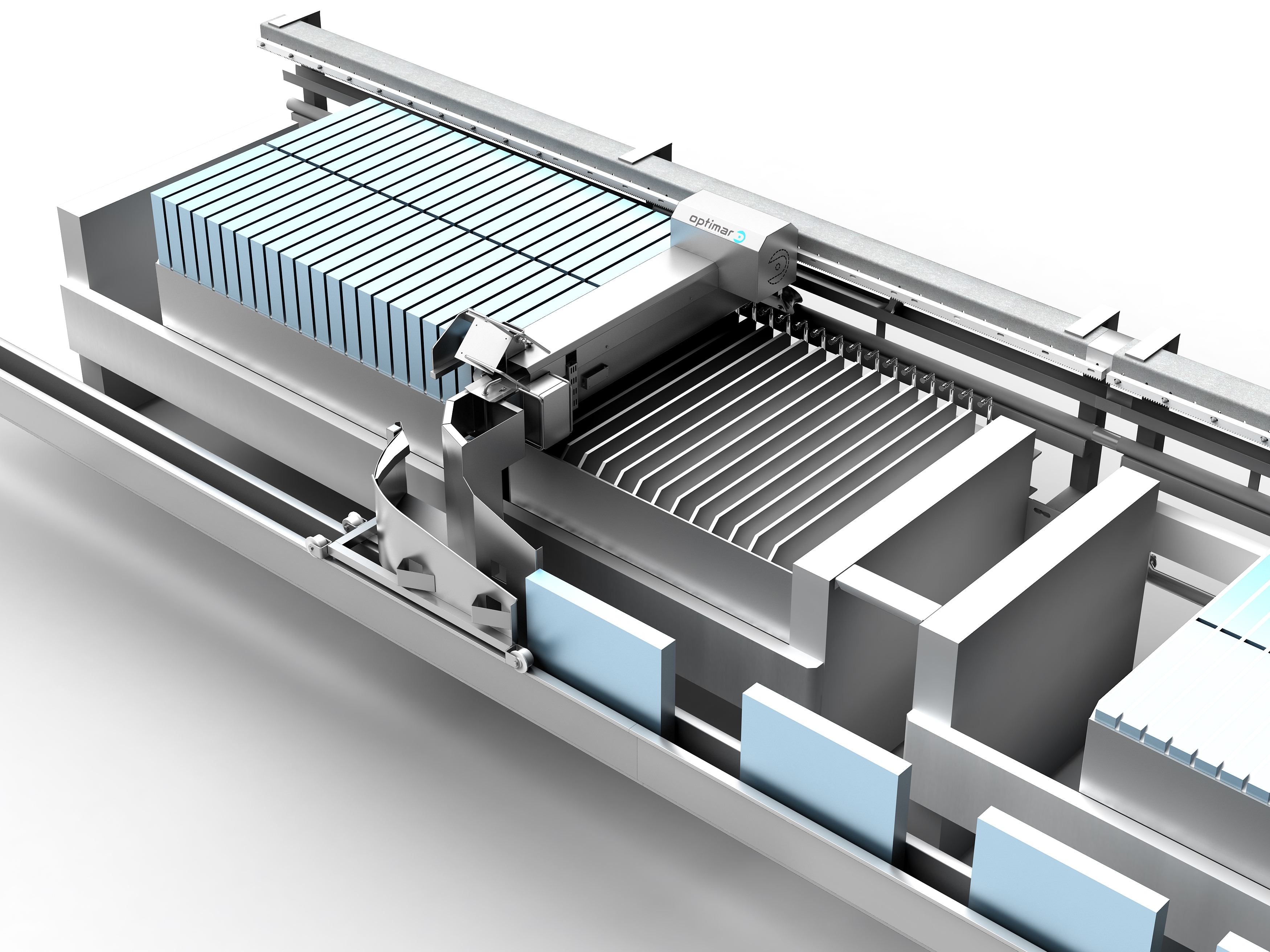

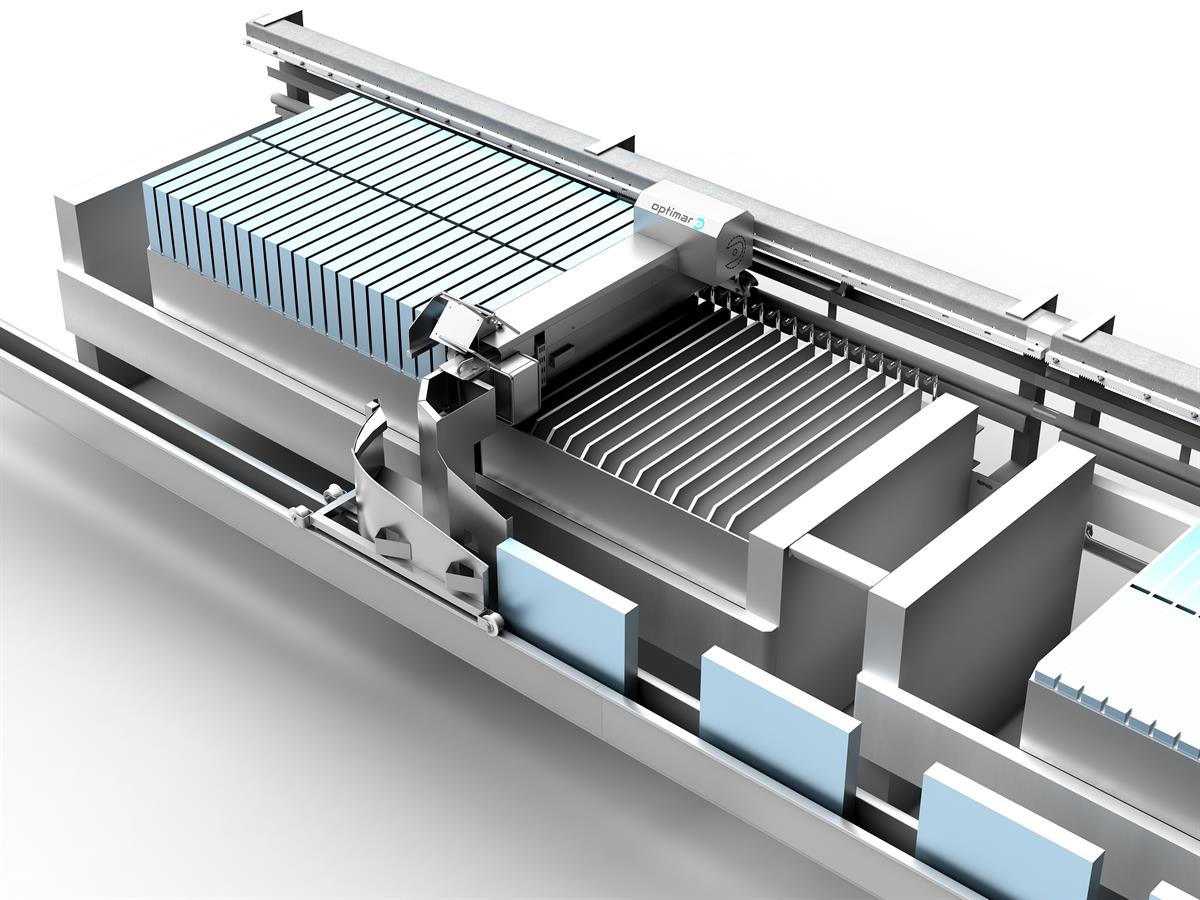

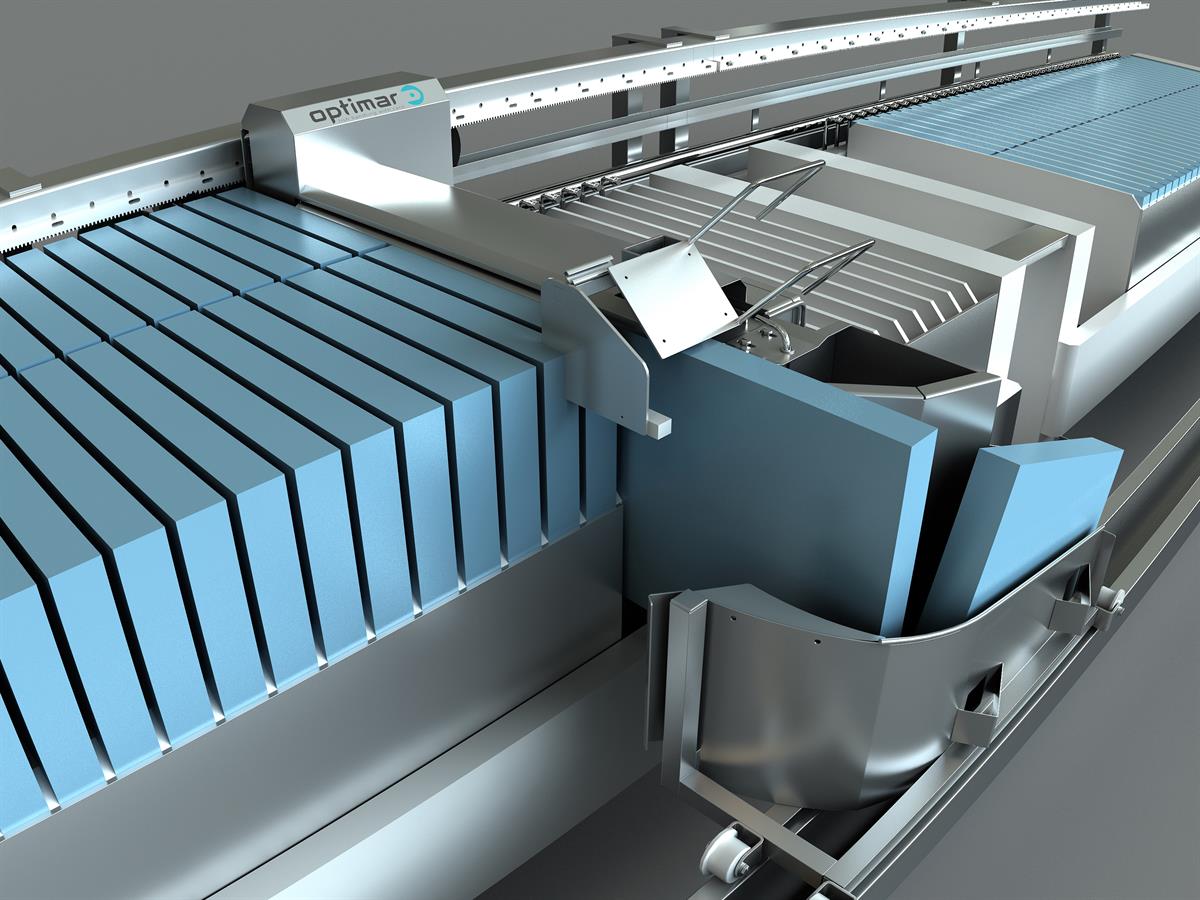

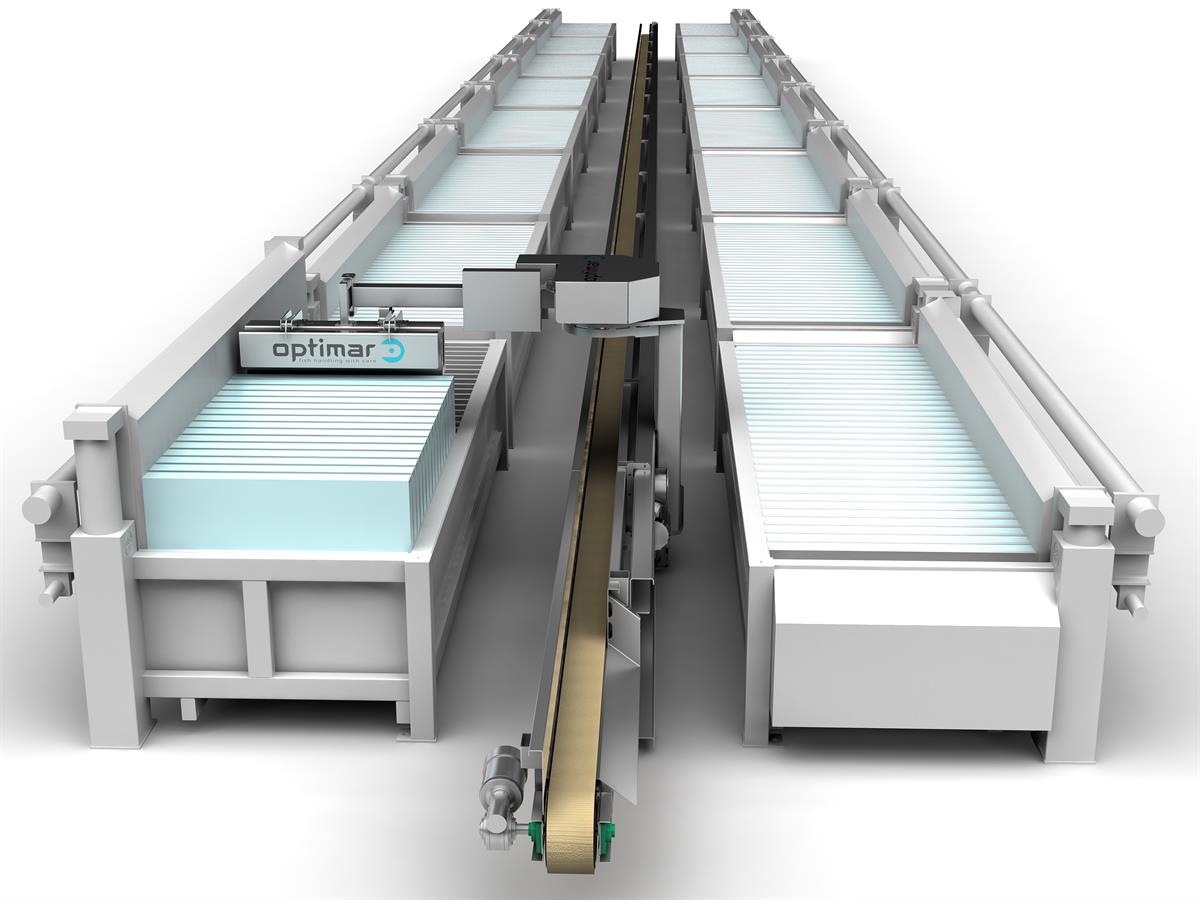

Automatic systems for vertical freezers

Leading the way

For OptiFreeze, however, these unique features are simply basic standards:

- reliable and durable in all operating environments

- eliminate manual handling of heavy, cold loads

- operate at full potential in limited spaces

- ejector technology releases frozen blocks without warming, defrosting

- no risk of leakage

- off-loading conveyor takes very little space

All Optimar vertical-freezer solutions are designed to handle two half-blocks or one whole and transport them at heights above floor level that ensure safe and clean handling. Unlike most systems, the Optimar units can service an entire line of freezers rather than only one.

Each of the systems is designed to be installed wherever a person can stand. They require no extra ceiling height, for example, and they can easily be positioned to handle space limitations caused by pillars, bulkheads or other equipment.

Optimar’s unloading solutions for vertical freezers eliminate the use of electrical sensors that areoften unreliable in extremely cold environments.The unloading units are separate from the freezer, however, so freezing can continue if the unloader is down.

V1

Fully automatic side-ejection system. Requires compatible vertical plate freezers.

V2

Semi-automatic side ejection system. Requires compatible vertical plate freezers.

V3

Fully-automatic unloading system using one robotic arm to off-load blocks (two halves or one whole) from two freezer lines. The robotic arm can move along the lines in either direction and can be used with any standard vertical plate freezers.

Service

Automatic systems for vertical freezers

Leading the way

For OptiFreeze, however, these unique features are simply basic standards:

- reliable and durable in all operating environments

- eliminate manual handling of heavy, cold loads

- operate at full potential in limited spaces

- ejector technology releases frozen blocks without warming, defrosting

- no risk of leakage

- off-loading conveyor takes very little space

All Optimar vertical-freezer solutions are designed to handle two half-blocks or one whole and transport them at heights above floor level that ensure safe and clean handling. Unlike most systems, the Optimar units can service an entire line of freezers rather than only one.

Each of the systems is designed to be installed wherever a person can stand. They require no extra ceiling height, for example, and they can easily be positioned to handle space limitations caused by pillars, bulkheads or other equipment.

Optimar’s unloading solutions for vertical freezers eliminate the use of electrical sensors that areoften unreliable in extremely cold environments.The unloading units are separate from the freezer, however, so freezing can continue if the unloader is down.

V1

Fully automatic side-ejection system. Requires compatible vertical plate freezers.

V2

Semi-automatic side ejection system. Requires compatible vertical plate freezers.

V3

Fully-automatic unloading system using one robotic arm to off-load blocks (two halves or one whole) from two freezer lines. The robotic arm can move along the lines in either direction and can be used with any standard vertical plate freezers.