About Aquaculture

State of the art equipment

Optimar has extensive experience in delivering products and solutions for aquaculture and fisheries worldwide.

Our expertise in the field has positioned us as a preferred partner within design and engineering, as well as service. A minimum level of stress for the fish equals a high quality product at the end of the process.

Our equipment for industrial processing of fish involves no chemicals and gentle handling in high capacity systems – both standardized and custom made. Our products span from sea lice removal and robot palletizing systems to electric stunning machines and mort handling.

Design

Sophisticated, robust, efficient

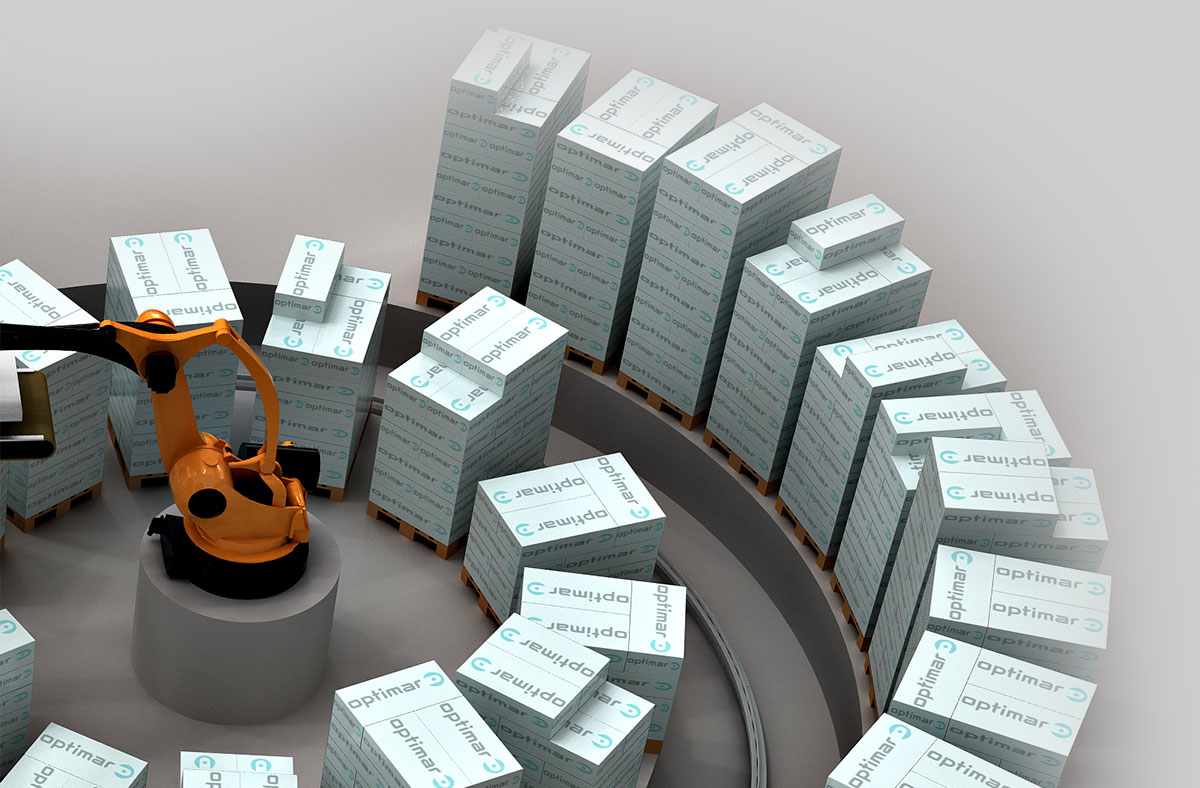

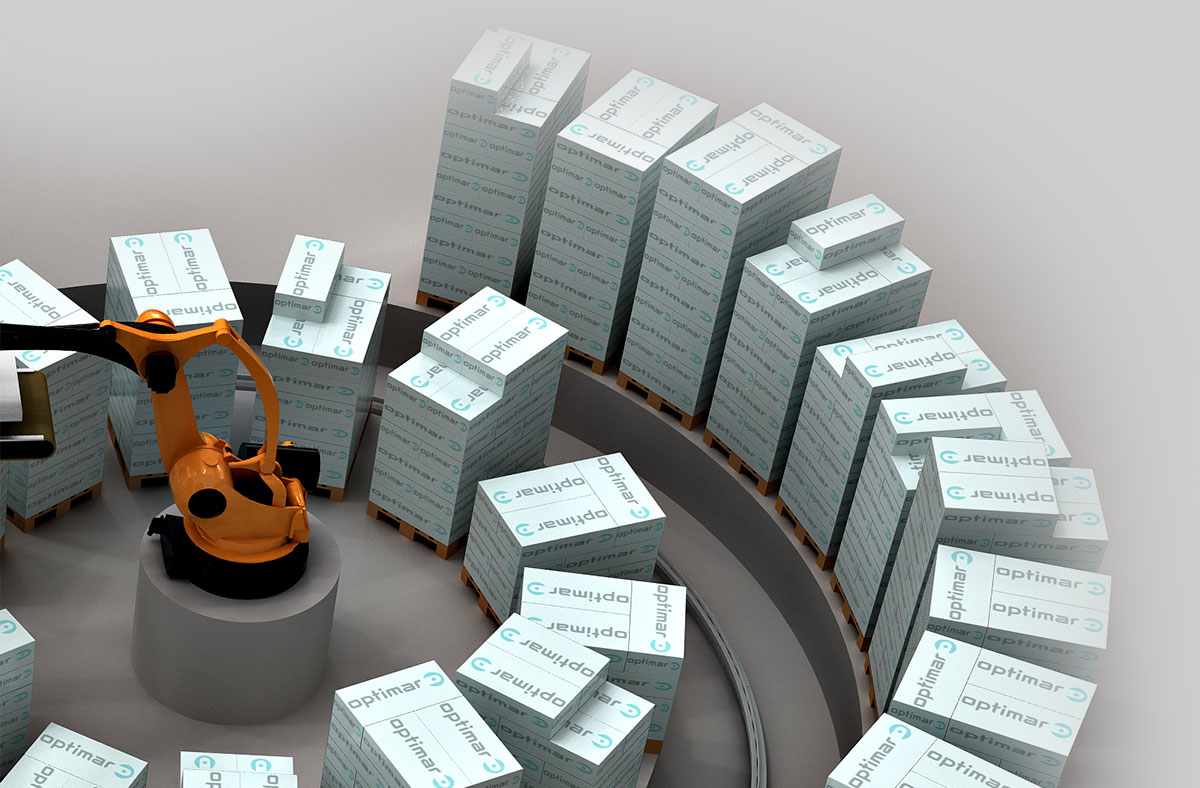

The center of activity

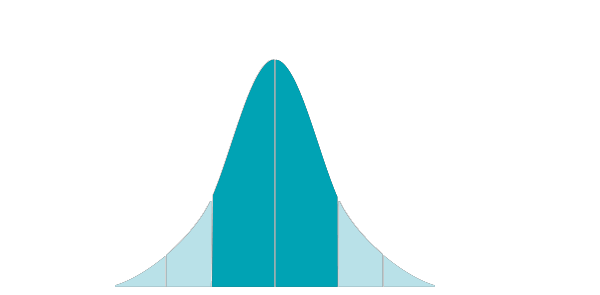

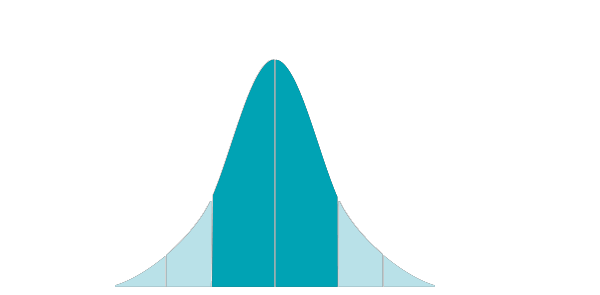

Optimar’s control system uses common sense or, more technically, the statistics of a normal “bell curve” to position pallets around the robot. Since the robot handles the most common product type most often, these pallets are placed closest to the robot’s pick-up point. This minimizes the time and distance the robot uses for the most repeated movement.

Similarly, pallets for less common product categories are placed symmetrically, side to side, around the circle until pallets for the least common items, the extremes of the curve, are in positions furthest from the pick-up point.

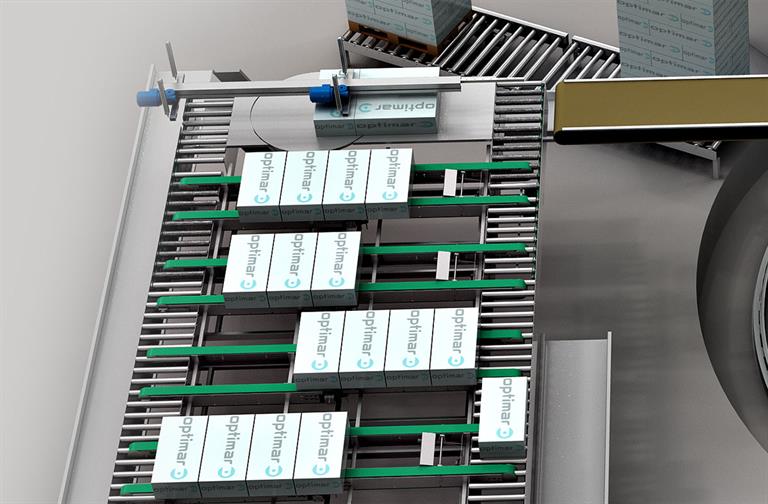

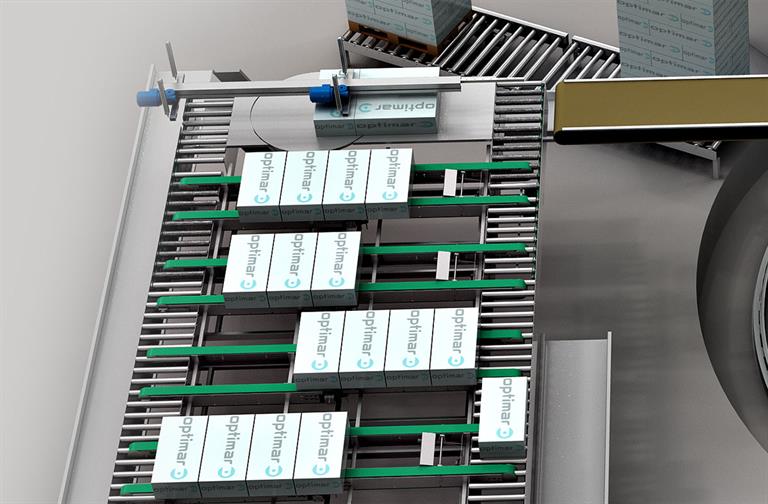

In-feed conveyor and buffer

The standard conveyor system feeding the robot can be expanded to provide a temporary storage area where small quantities of less common product types can be collected and held until the pallet from the outer circle is in position.

A booster speeds up handling by preparing a full layer of cartons for the robot to grasp and place on a pallet. The control system keeps track of the layering scheme so the robot automatically turns the layer to ensure the load on the receiving pallet remains stable and well-balanced.

The control system together with the temporary storage synchronizes the workflow, ensuring the robot always has products and pallets to load.

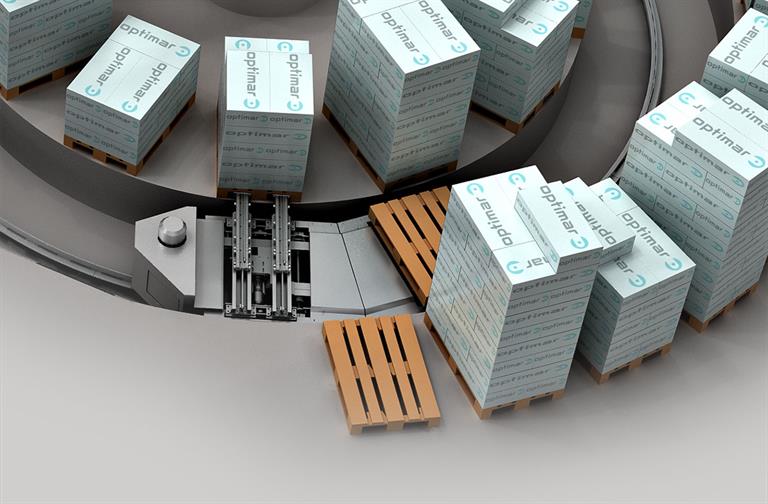

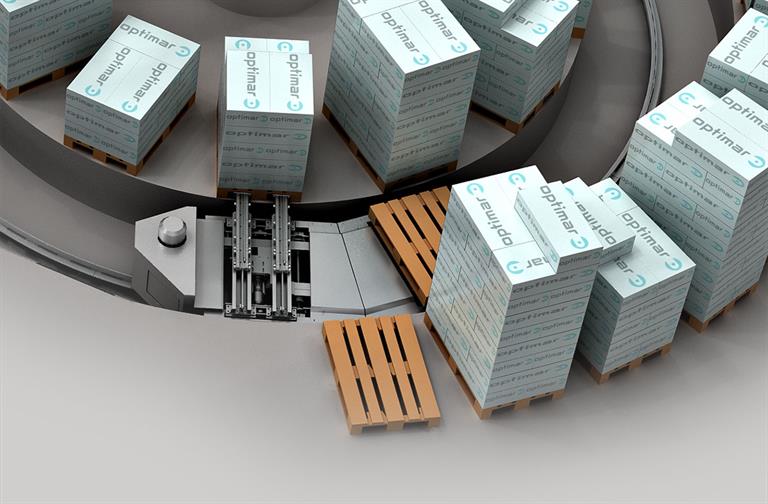

Pallet trolley

Synchronized with all the other action, the control system moves a two-bed trolley around the outside of the palletizing circle to pick-up a full pallet and replace it with one that is empty or, when the time is right, a pallet from the outer ring of less common product types.

A full pallet that is ready for shipping is moved out of the palletizing area while a pallet only partially filled with a special product type may be moved back to the outer circle waiting area until the control system determines there are, once again, enough boxes in the buffer to bring the pallet forward for further loading.

Outer circle

Optimar’s unique outer-circle concept significantly expands the capacity of the Palletizing Center, providing the option of handling up to nearly 30 pallets more than just the basic stations of the inner circle.

The outer circle serves as a holding area for partially filled pallets of less common products that may be sorted by type, weight, quality, quantity, content, etc. The palletizing control system determines when enough boxes of a certain type have been set aside in intermediate storage and can be loaded efficiently onto the corresponding pallet in the outer circle without interrupting the workflow.

Service

Sophisticated, robust, efficient

The center of activity

Optimar’s control system uses common sense or, more technically, the statistics of a normal “bell curve” to position pallets around the robot. Since the robot handles the most common product type most often, these pallets are placed closest to the robot’s pick-up point. This minimizes the time and distance the robot uses for the most repeated movement.

Similarly, pallets for less common product categories are placed symmetrically, side to side, around the circle until pallets for the least common items, the extremes of the curve, are in positions furthest from the pick-up point.

In-feed conveyor and buffer

The standard conveyor system feeding the robot can be expanded to provide a temporary storage area where small quantities of less common product types can be collected and held until the pallet from the outer circle is in position.

A booster speeds up handling by preparing a full layer of cartons for the robot to grasp and place on a pallet. The control system keeps track of the layering scheme so the robot automatically turns the layer to ensure the load on the receiving pallet remains stable and well-balanced.

The control system together with the temporary storage synchronizes the workflow, ensuring the robot always has products and pallets to load.

Pallet trolley

Synchronized with all the other action, the control system moves a two-bed trolley around the outside of the palletizing circle to pick-up a full pallet and replace it with one that is empty or, when the time is right, a pallet from the outer ring of less common product types.

A full pallet that is ready for shipping is moved out of the palletizing area while a pallet only partially filled with a special product type may be moved back to the outer circle waiting area until the control system determines there are, once again, enough boxes in the buffer to bring the pallet forward for further loading.

Outer circle

Optimar’s unique outer-circle concept significantly expands the capacity of the Palletizing Center, providing the option of handling up to nearly 30 pallets more than just the basic stations of the inner circle.

The outer circle serves as a holding area for partially filled pallets of less common products that may be sorted by type, weight, quality, quantity, content, etc. The palletizing control system determines when enough boxes of a certain type have been set aside in intermediate storage and can be loaded efficiently onto the corresponding pallet in the outer circle without interrupting the workflow.