About Onshore Fish Handling

More profitable processing

We strive to make fish handling with care achievable throughout the whole handling process.

Therefore, Optimar has played a major role in designing and producing automatic and robotic systems that have made fish processing easier, faster, safer, cleaner and more profitable

Design

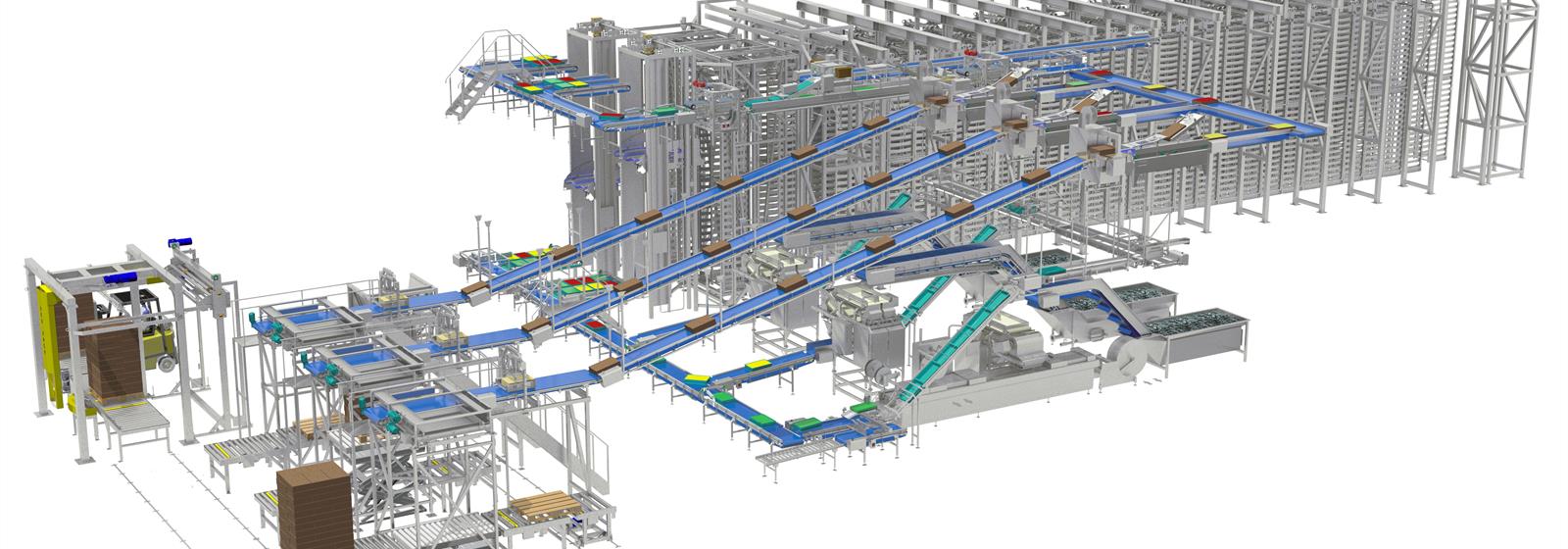

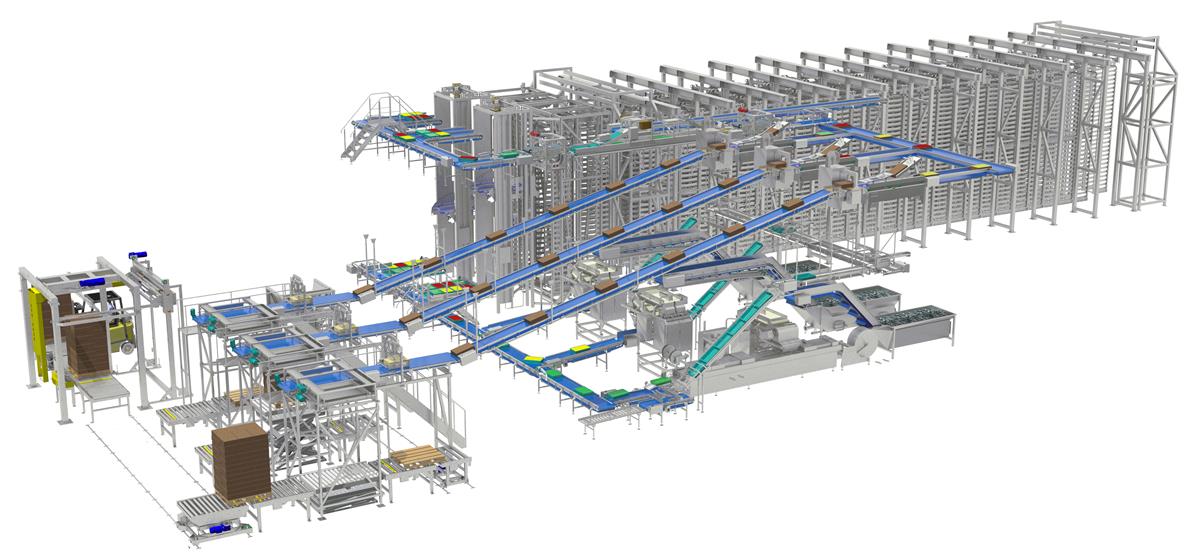

Solutions, design and engineering

Optimar is known for it's ability to analyze technical challenges that call for a combination of engineering disciplines.

Optimar customers know our machines work in extreme conditions ? they know we do too!

The depth and breadth of expertise needed to explore solutions for you is, literally, under our own roof. This expertise ranges from production logistics and design to civil, electrical and mechanical engineering to automation and programming development.

Optimar designs it's own equipment to interface with any other solution currently available. This means you don’t need to decide in advance the suppliers of your other process-specific solutions. It also means we can work together to choose the technology that best fits the product, the functionality and your price range. Our designers work with you to define specifications and a strategy for implementing them. We design and fabricate standardized as well as customized systems and we have a catalog of contacts to help you select other suppliers for other equipment.

To help make your plans a reality, our skilled engineers can serve as project managers if you need one, or they will work closely with yours if you have one. In either case, Optimar is your partner for the long-term. Flexibility, quality, and reliability define the goals of Optimar’s team of experienced, creative engineers. They work closely with you to find the best, most reliable, most cost-effective solutions to strengthen your competitive advantage.

From expertise to innovation

Optimar has a well-established track record of creative success when off-the-shelf options are not options at all. So strong, in fact, that many custom solutions have themselves become must-have, off-the-shelf standards.

.tmb-xl-narrow.jpg?sfvrsn=338efcd0_3)

Sometimes, resolving a design or logistics dilemma is simply a matter of adapting a well-proven solution to meet a special need.

Sometimes, however, the situation requires a totally new vision and Optimar engineers are experts at transforming innovative ideas into realistic solutions.

We have acquired our reputation for creative thinking by developing customized solutions that meet the exacting standards of the ever-changing food processing industry. Over 40 years ago, for example, we helped transform a branch of the industry, fish processing. We did this by designing and delivering the world’s first factory to process fish when they are freshest – on board a ship at sea.

Optimar continues to take the risks that innovative results often require at the beginning. The priorities that gave us the security to venture into totally new territory in the past, remain the same today:

- flexibility

- customer loyalty

- balancing requirements, wishes and budgets

- careful assessment of new technologies

- curiosity

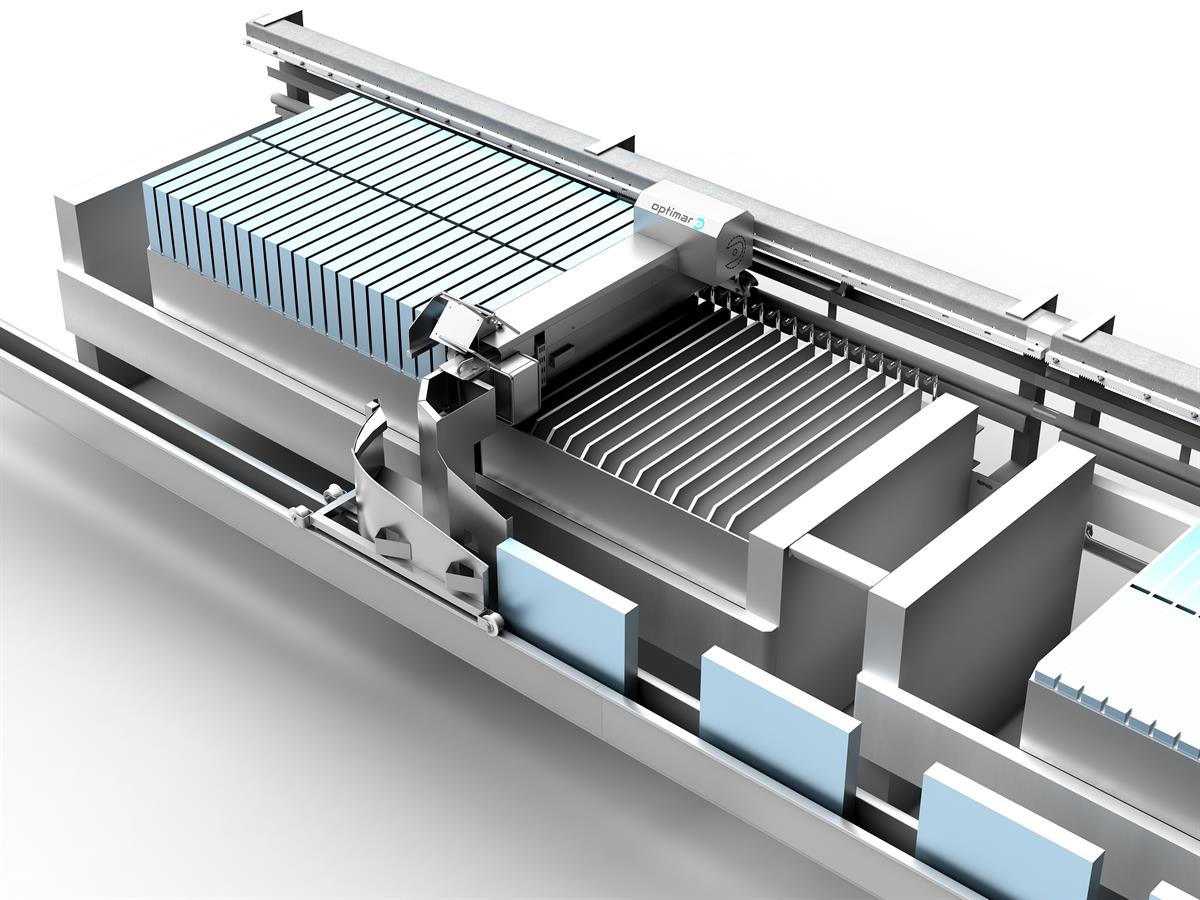

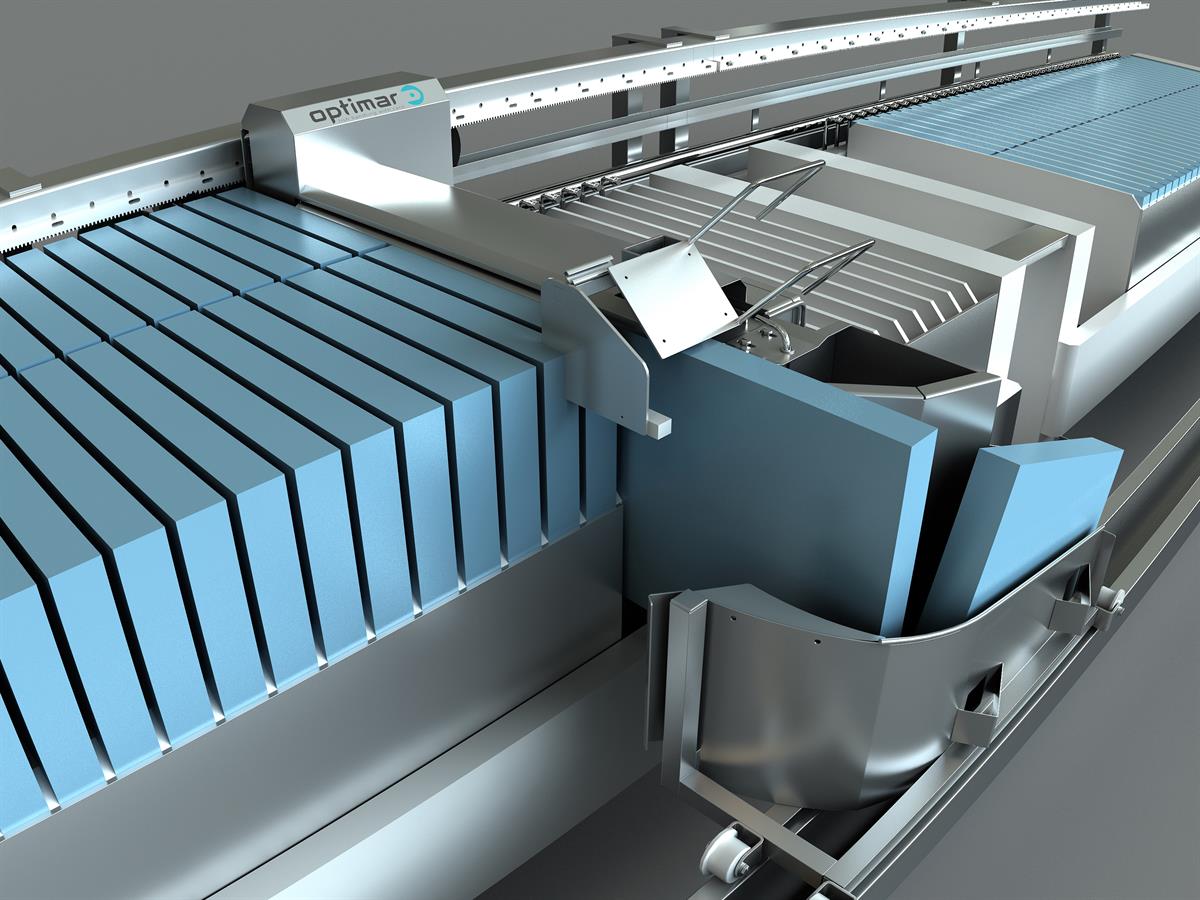

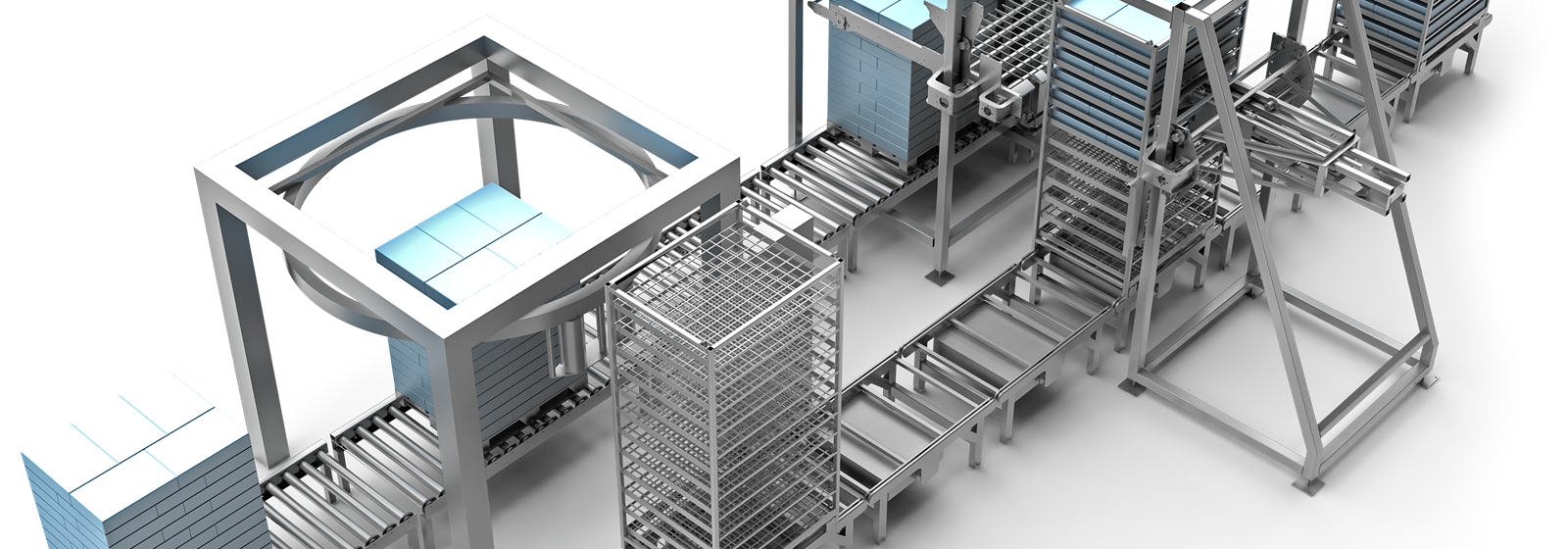

Block ejector

Block ejector Plastic feeder

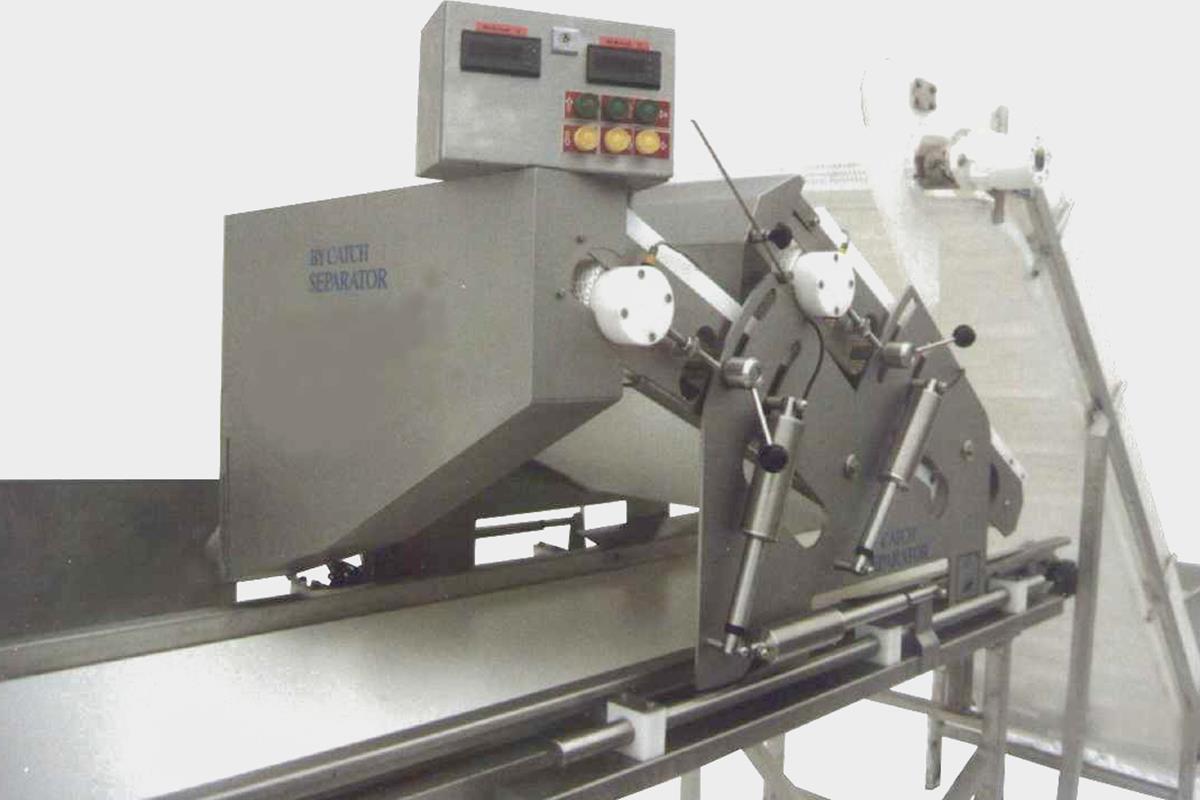

Plastic feeder Bi-catch shrimp separator

Bi-catch shrimp separator.tmb-lg.jpg?sfvrsn=338efcd0_1) Box-cover applicator

Box-cover applicator Packing machine

Packing machine Carton erector

Carton erectorDelivering from beginning to end

In the food processing industry, hygiene is absolutely critical. Equipment must be easy to keep clean while it is operating and easy to clean when it is not.

Safe, reliable & easy to clean

Optimar’s standards of sanitary excellence are based on years of experience in the fish processing industry. This means we have also had years of experience meeting the strict food-safety regulations of the U. S. Department of Agriculture (USDA) as well as those of Norway, Spain and other governments around the world. To ensure the health and safety of workers and consumers, our systems are designed to exceed, not just meet, regulations for sanitation and cleanability.

Optimar uses only materials, such as stainless steel, that are as cleanable as they are durable. Although the space available for conveyors may be limited, we always try to design a system that ensures a comfortable height for workers, minimizes the risk of unintended product contamination, and provides easy access for cleaning.

Carton carousel

Bulk feeder

Bulk feeder Roller conveyor

Roller conveyorControlling

Functionality from top to bottom

Robust and reliable. Flexible and modular. Cost effective. Hanging racks. Interfaces with OptiControl. Conserves energy.

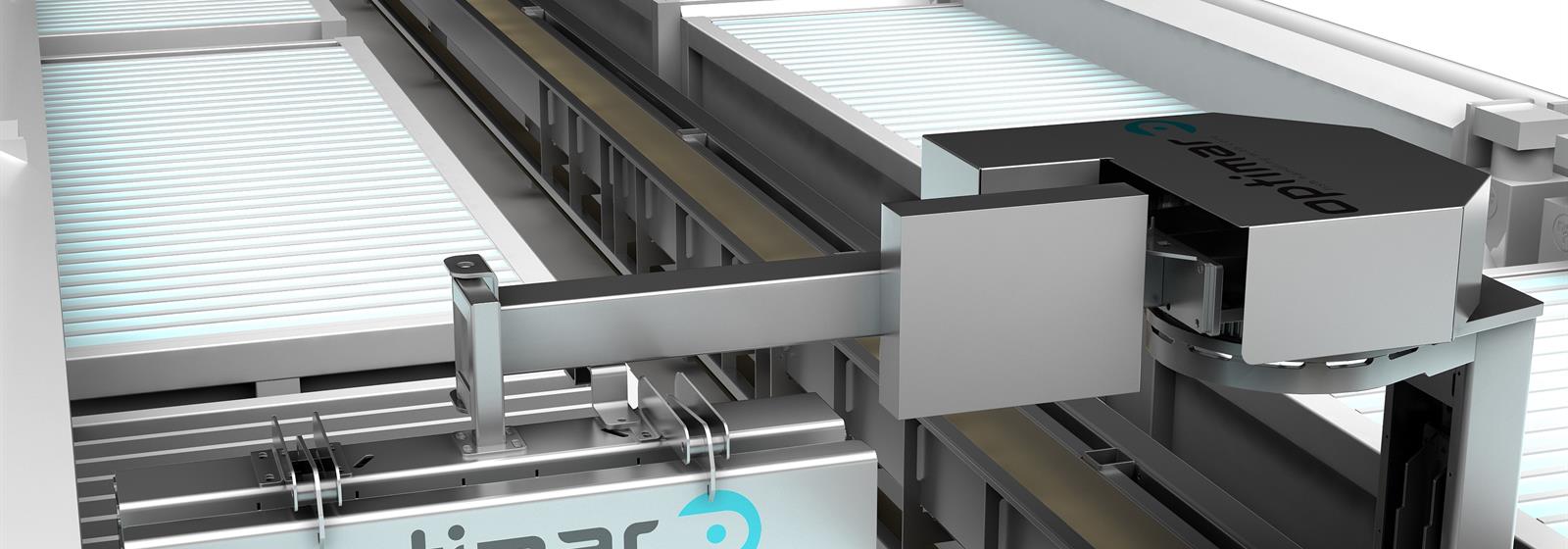

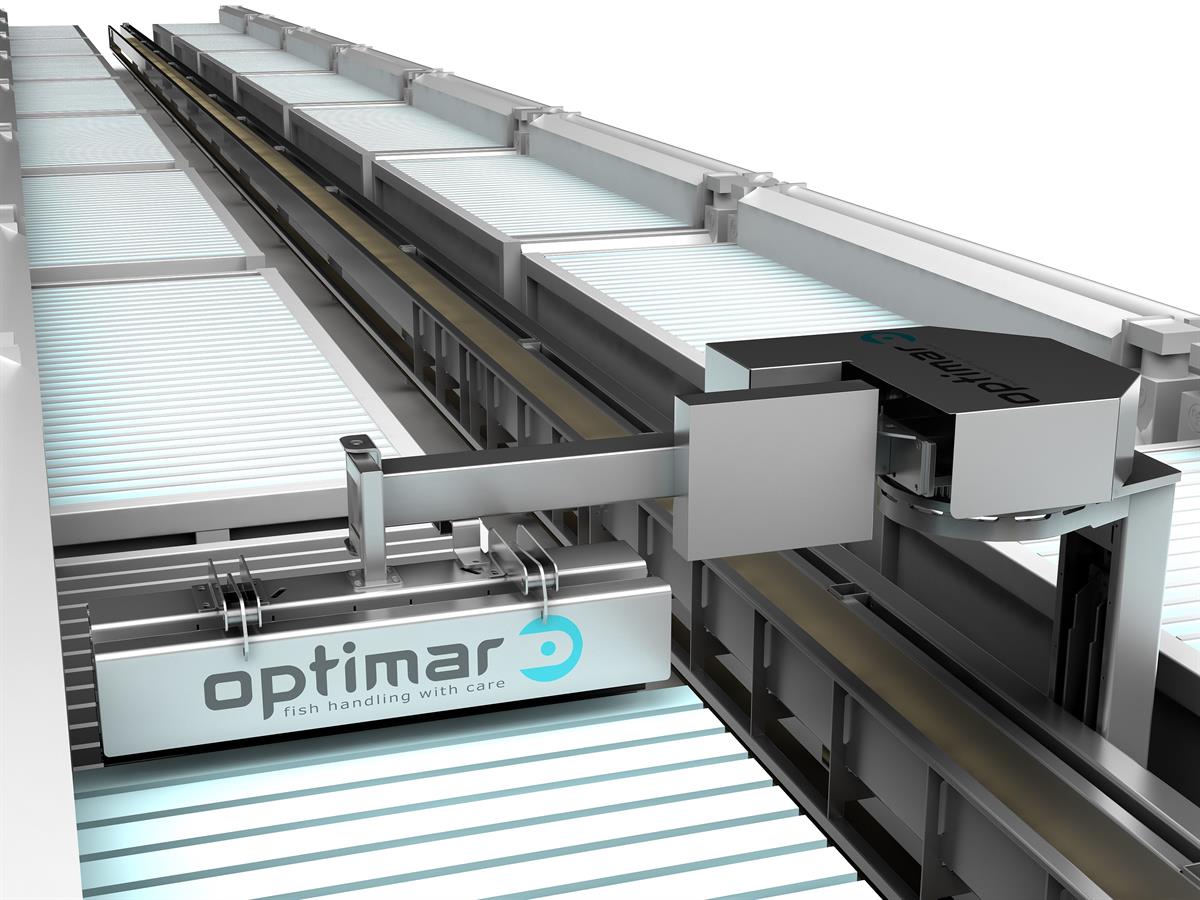

Robust and reliable

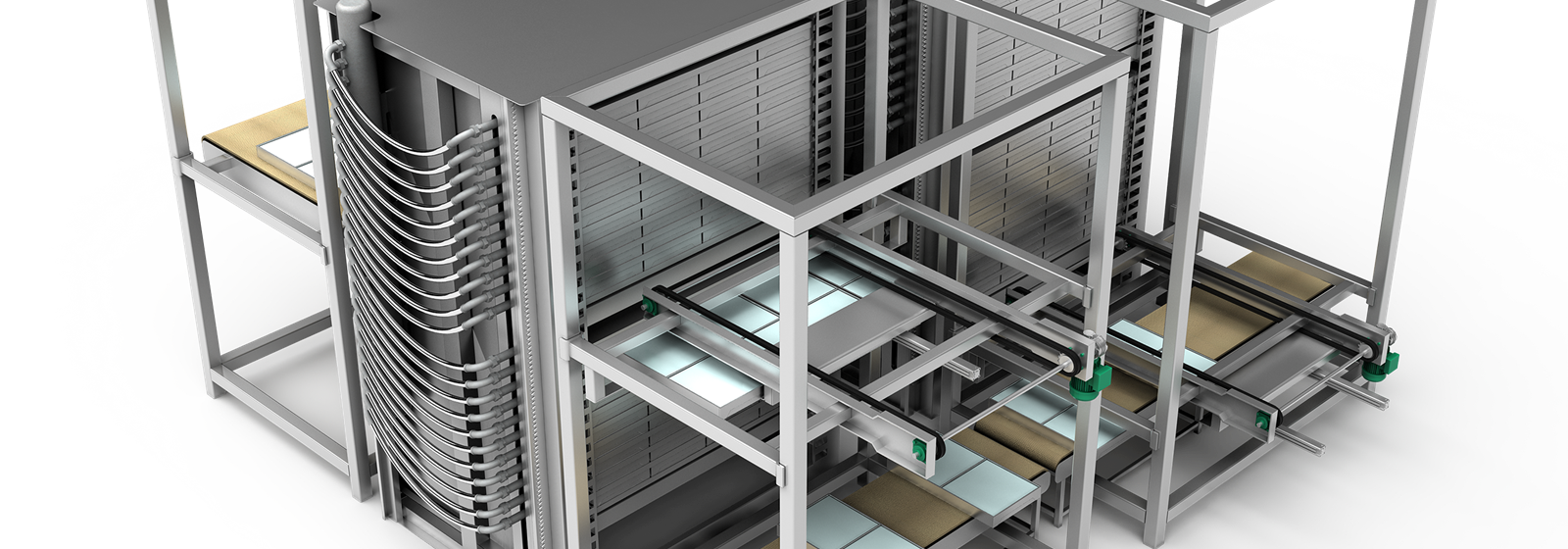

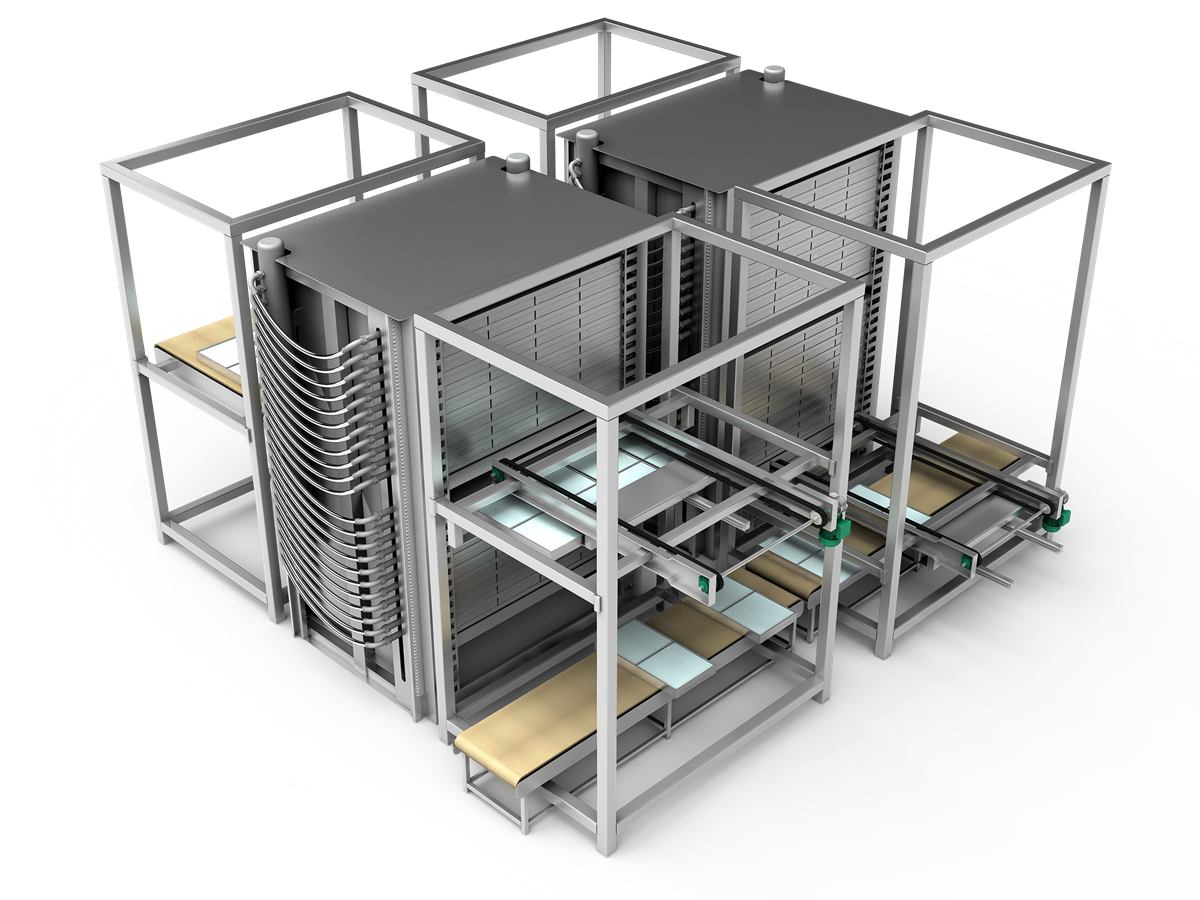

The frame, racks and all other parts of OptiFreeze Blast are fabricated by Optimar and customized according to the product, freezing requirements and volume.

OptiFreeze Blast requires only minimal maintenance. It has few moving parts so it avoids problems common to more standard systems working non-stop in extremely cold conditions.

Like all Optimar systems, if a problem occurs OptiFreeze Blast has alternatives to ensure production continues and downtime is minimal.

Flexible and modular

Each Blast freezer may contain up to several hundred racks and, of course, a production facility may have many Blast freezers.

Blast can simultaneously handle different types of products that may require different freezing times. The system serves as a buffer, or temporary storage if, by plan or necessity, the workflow is not constant.

Cost effective

Blast’s design eliminates the need for manual loading, forklifts and forklift drivers. This results in significant savings in labor and equipment costs. It also reduces the potential for onsite accidents and damage to buildings or surrounding equipment.

Existing refrigeration equipment can be easily adapted and used by OptiFreeze Blast. Filling is continious, up to one ton in five minutes, generating significant savings.

Hanging racks

The racks and all OptiFreeze Blast mechanisms are hanging above floor level. This means the floor is totally flat and easily accessible for cleaning.

Columns of racks are suspended from steel rails and roll on stainless steel wheels that slide smoothly and easily. Even when filled, a rack can be moved along by a simple push of the hand.

Racks remain inside the Blast at all times but can be easily released and removed if necessary.

Interfaces with OptiControl

Blast is easily managed and monitored from Optimar’s OptiControl NetCenter.

Real-time and past performance data are always available to improve production, eliminate bottlenecks and optimize processing. NetCenter also notifies you immediately of any alarms or potential problems.

Conserves energy

The product enters and leaves OptiFreeze Blast through small openings via an automatic robotic system. Energy savings are significant because no large doors are repeatedly opening and closing. Freezing racks remain inside the refrigerated area throughout the process so no energy is wasted warming up or cooling down the steel frames.

Loading and unloading are continuous – one stations and one rack at a time – so, unlike traditional static blast freezers, there are no energy peaks or valleys.

Tests by SINTEF prove the flow of air is evenly distributed through the products.

Continuous freezing also eliminates the risk, common to static tunnel systems, of compromising product quality due to warming, dripping or leaking when products are waiting for a tunnel to be filled.

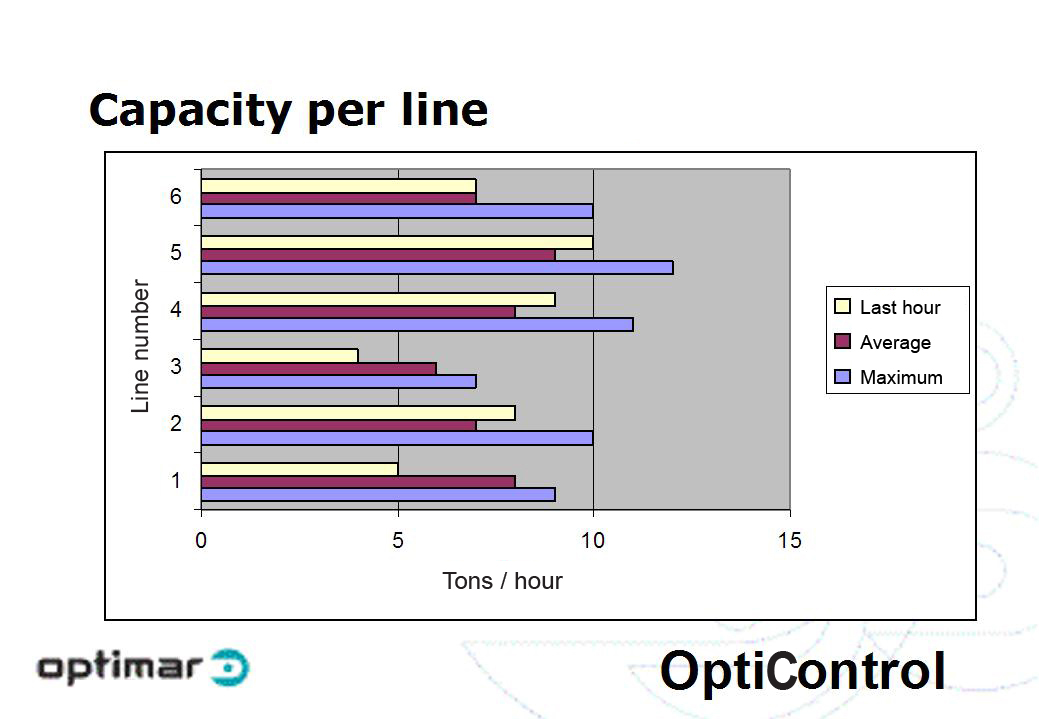

By machine, by line or by system

You can link as many Optimar systems as you wish to OptiControl NetCenter and you can adjust the number at any time.

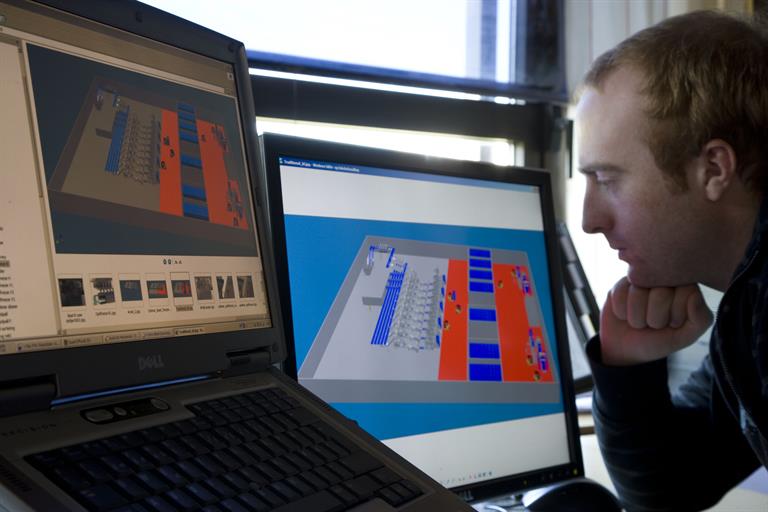

OptiControl NetCenter

Access can be as secure or limited as necessary to part or all of the network, to specific functions and/or to specific data. NetCenter makes it easy to ensure that the right person receives or has access to the right information. The general manager, for example, may be interested in different information than the machine maintenance manager.Current alarms and histories

OptiControl EasyTouch and ProLine issue an alarm signal when sensors detect a problem such as an interrupt in the work flow. The system notifies you immediately of the location, the component or processing line affected, and the diagnosis.

Most problems can be solved quickly and directly online, reducing downtime, maintaining production levels and saving money. If NetCenter is part of your OptiService Agreement, many problems can be corrected without an on-site visit.

Real-time and past performance

In addition to displaying all types of real-time information, OptiControl keeps a database of past-performance. This makes it easy to generate reports, graphs or tables reflecting, for example, current or past production levels, averages, maximums or minimums during a period, capacity variations through a run cycle or day, and so forth.

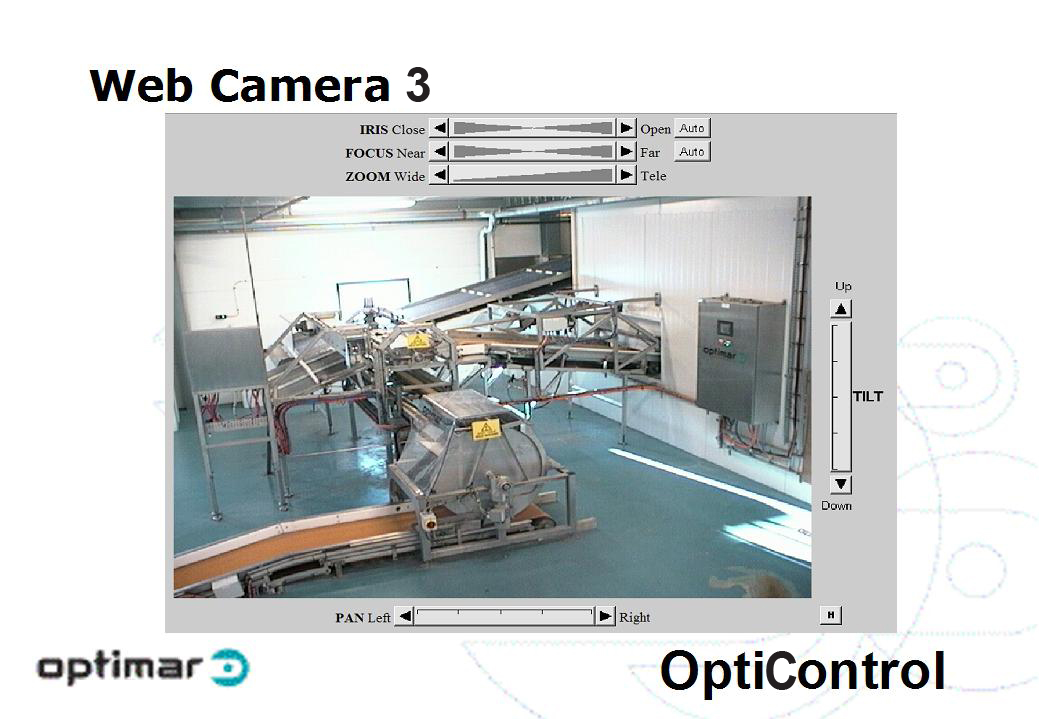

Live-action web cameras

Strategically positioned web cameras connected to OptiControl NetCenter enable you to study live video at any time. Regardless of your location, for example, this is especially useful to monitor and adjust the workflow, facilitate the diagnosis and correction of a problem, or watch for operating issues that might suggest preventive maintenance before a breakdown.

The high-resolution cameras used by Optimar are extremely flexible. You can use the keyboard or touch-screen from wherever you are to scan the area up or down, left or right, zoom in or out for close inspection or an overview, adjust the input level of light, etc.

Power in the palm of your hand

The software that runs Optimar’s automatic systems is as unique and advanced as the equipment itself. A robot, like ours in the circular center, is only as smart as the EasyTouch program controlling it and ours is very, very smart

OptiControl NetCenter

Similarly, Optimar’s processing line systems may be based on common-sense logic but, when they repeatedly generate significant improvements in production and profitability, it is clear that ProLine programs support intelligent, carefully coordinated, and extremely efficient processing strategies.

With this kind of in-depth power and information at the minute-by-minute operating levels, it is easy understand the magnitude and value of the information available to you when they are all connected. OptiControl NetCenter is Optimar’s unified network of the control systems for the processing lines and their primary components.

NetCenter is a web-based PMC system. This means all the information you need to monitor, manage and maximize production is available at any time from any location via any device as long as you have access to the Internet. Smartphones and personal digital assistants (PDAs) put the power of OptiControl NetCenter in the palm of your hand.

The alarm and performance data reported and retained by OptiControl NetCenter gives you a valuable tool for examining peaks and valleys in performance and taking corrective action accordingly. In other words, OptiControl NetCenter not only improves your processing overview, it helps you improve the entire production process by:

- optimizing the use of equipment

- minimizing the use of labor

- avoiding unnecessary stops and downtime

- balancing the workflow

- increasing capacities

- anticipating maintenance needs

- establishing a performance database

NetCenter’s connections with each ProLine and EasyTouch system are web-based. New connections, new functions, program updates and system upgrades can be made directly online.

Connected, coordinated, consistent

Optimar’s control programs for automating processing lines sound almost too good to be true – they quickly pay for themselves, they keep doing what they do best, they are out of sight.

OptiControl ProLine

An OptiControl ProLine system is a production assistant that works constantly, literally every second, to optimize and adjust the workflow in order to optimize production, product quality and your profit margin.

ProLine systems may be out of sight but the advantages are very visible:

- smooth, uninterrupted product flow.

- stable workflow and capacity levels.

- consistency in portion size.

- elimination of bottlenecks, overflows, blockages.

- near elimination of damaged, spoiled, wasted product.

OptiControl ProLine systems are logical programs (PLCs) developed by Optimar’s automation team specifically for the type of process being controlled – sorting, cutting/filleting, freezing, packing, boxing, palletizing, etc.

The goal, however, is always the same: to ensure the product is evenly distributed among the components of the processing line to facilitate effective, profitable processing.

A ProLine system is controlled from a centrally located touch-screen panel with the same features of access and durability as the OptiControl EasyTouch panel. ProLine monitors and manages each operation in the line to ensure each action is carefully synchronized and in accordance with the parameters defined relative to volume, speed, diversion settings, etc.

ProLine works towards a predefined processing capacity and coordinates the processing to ensure the goal is achieved. It adapts automatically to the batch size and the frequency with which it should be sent to each station in the line. The speed with which a station is filled is constantly adjusted to match the total capacity of the line.

Like EasyTouch, OptiControl ProLine tracks performance and alarm data and may be connected to OptiControl NetCenter to examine comprehensive summaries of real-time and past performance, monitor capacity levels and distribution, and so forth.

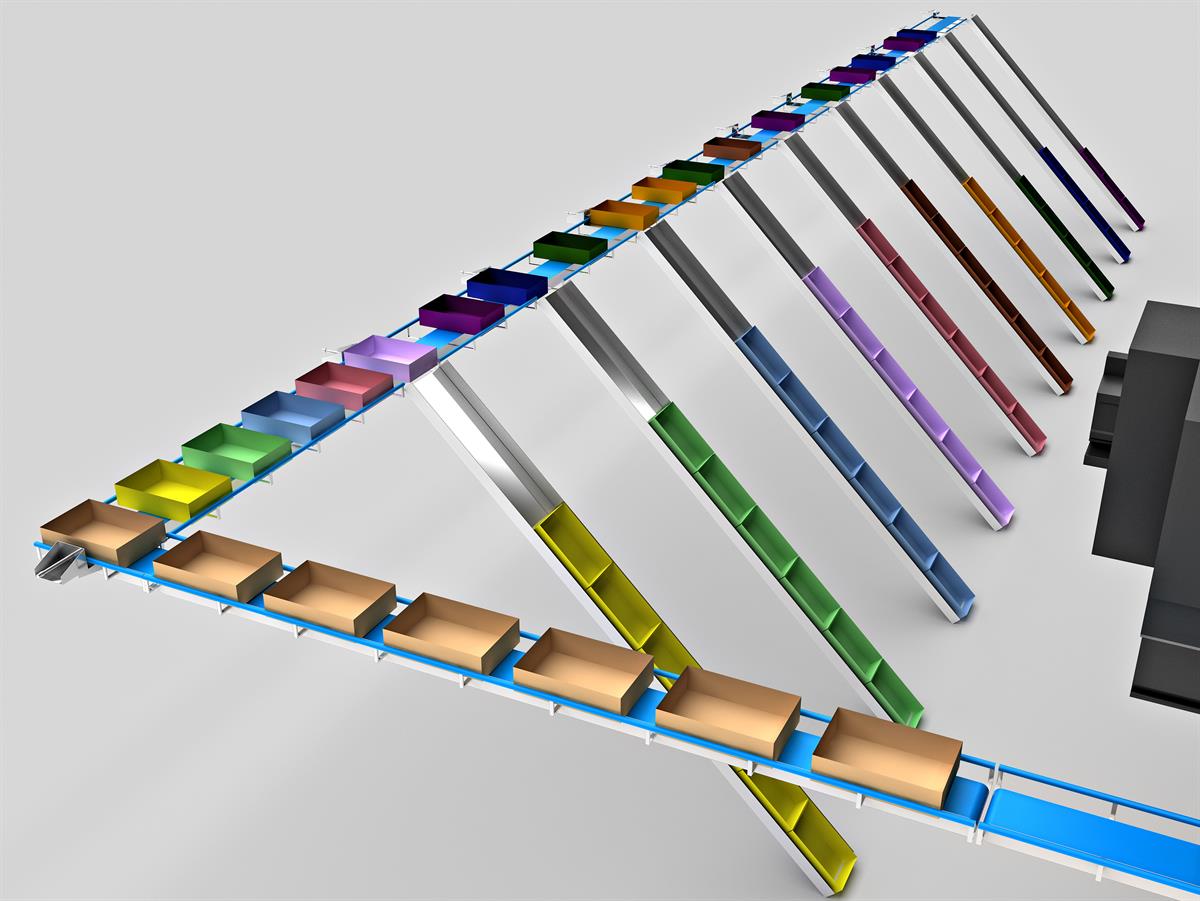

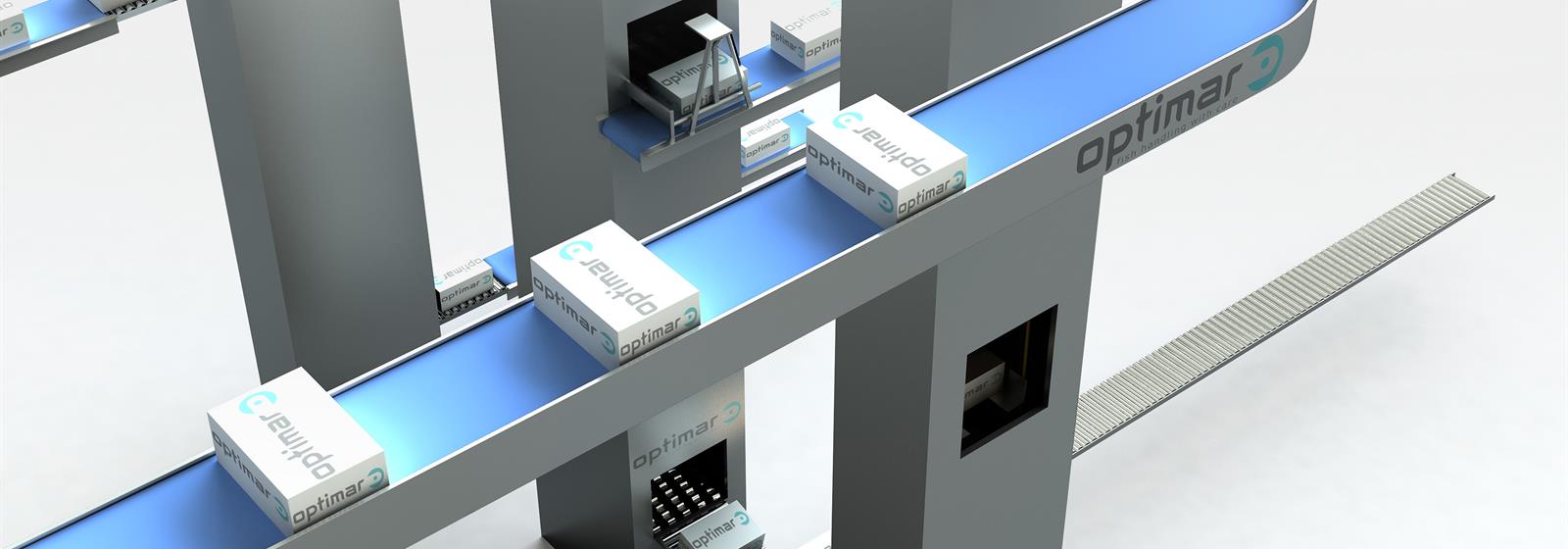

Box-by-box distribution

Sensors report when boxes are delivered, used or need replacing. Each station receives a continuous, well-spaced supply. If a carton is removed as damaged or as a spare the system is self-correcting without interrupting the flow.

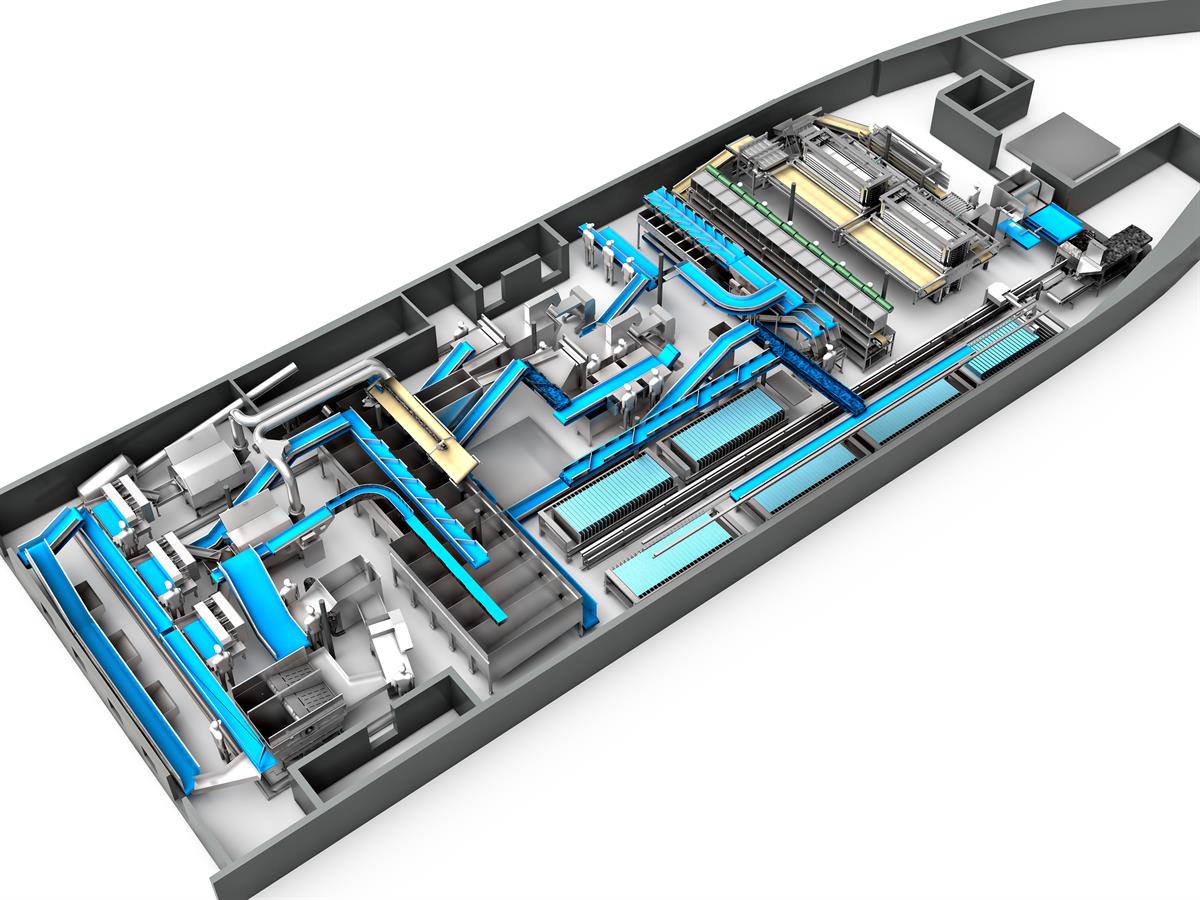

Onboard processing

Optimar has developed logical ProLine controls for a wide variety of processing systems including those onboard ships.

Power at your fingertips

Each automatic or robotic Optimar product has its own touch-screen panel to control its operation. The panels may look quite ordinary but, like the products themselves, they are unique.

Optimar makes the electrical cabinets and consoles that power Optimar equipment. We use the same high-quality stainless steel, to meet the highest international standards for dust and water resistance

In addition to flexible functionality and options on the inside, they must pass Optimar’s rugged test for durability under extreme conditions on the outside too. For instance, they must function without fail in extraordinary operating conditions that may be damp with humidity, wet with salt water or dry with heat.

Some touch-screen cabinets are fixed in position, some are mounted so they rotate up to 360o but all are positioned at comfortable working heights in the most convenient locations. As a result, they may be specially mounted for unusual equipment configurations and may be distanced from the main power cabinet.

The touch-screen displays are high resolution and in color so they are clearly readable from most angles in any lighting situation. The operating menus vary according to the Optimar product but the basic design and content of each graphical user interface are the same.

Navigation is straightforward and intuitive so even Optimar’s most sophisticated equipment can be easily and safely managed by a trained operator with minimal experience. Depending on the machine, the EasyTouch menu may include options to access capacity information or other performance data over a short period. More detailed, accumulated information is available from OptiControl NetCenter.

Optimar machines with touch-screen panels can be linked to other Optimar equipment and monitored collectively via OptiControl NetCenter for a total network overview.

All EasyTouch menus include:

Language options

English, Norwegian and Spanish are standard options with all Optimar systems. EasyTouch menus are available in other languages upon request.

System and process diagrams

In automatic mode, the operator works from an on-screen diagram of the system showing each step of the process. In manual mode, the operator controls each phase of the process from a display with manual options specific to the phase of operation.

Visible and understandable error alerts

Alarm signals indicating a fault or stop are clearly visible and, in automatic mode, the area causing the problem is precisely highlighted on a schematic diagram.

Behind the screens, ahead of the times

What sets Optimar apart are not just the designs of our processing systems, not just the way we work with you, and not just the solutions that result.

What sets Optimar apart are not just the designs of our processing systems, not just the way we work with you, and not just the solutions that result.

What does set us apart are the systems you don’t see that control the systems you do see.

Optimar’s automation team includes specialists in electronic, pneumatic and hydraulic technologies and a team of software engineers with in-depth skills to synchronize the movements of every part of every Optimar system.

This means the software and operating systems that drive each Optimar machine, processing line or total facility are unique to Optimar.

It also means the systems are understood by an entire team of programmers and specialists, not just one or two, and each person is committed full-time, in-house to fulfilling Optimar’s commitment to you.

Control EasyTouch – machine-specific touch-screen systems to control operation, define default settings, receive alarm signals, examine short-term alarm history, review performance data, and more.

OptiControl ProLine – central logical control systems (PLCs) specific to a processing line, freezing system, palletizing system or other “logical” production area to ensure the workflow is smooth and distribution among the components of the line is optimized.

OptiControl NetCenter – a web-based Production Management Control (PMC) network connecting all Optimar systems for a total overview of real-time and past performance, real versus theoretical capacities, bottlenecks and downtime, alarms and much, much more.

An entire processing facility can be monitored, managed and maintained via the Internet using a computer, personal data assistant (PDA) or telephone with Web access from any location around the corner or around the world. A powerful, sophisticated tool to help ensure your business is achieving its full potential and profit.

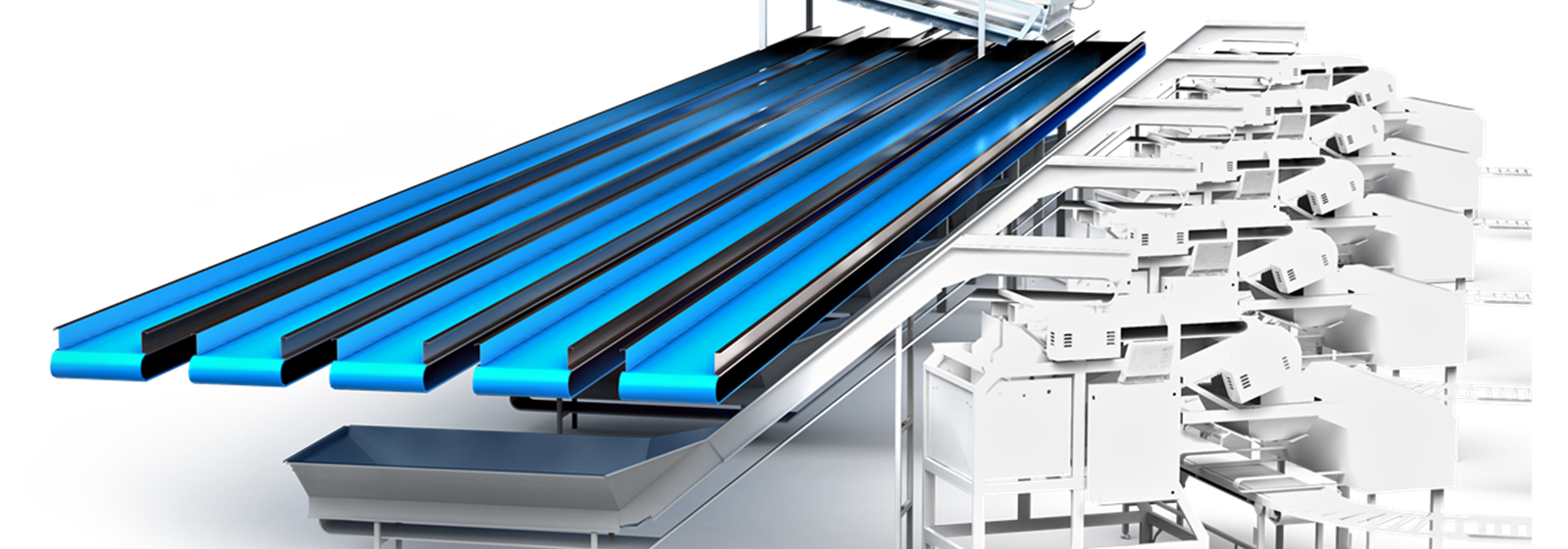

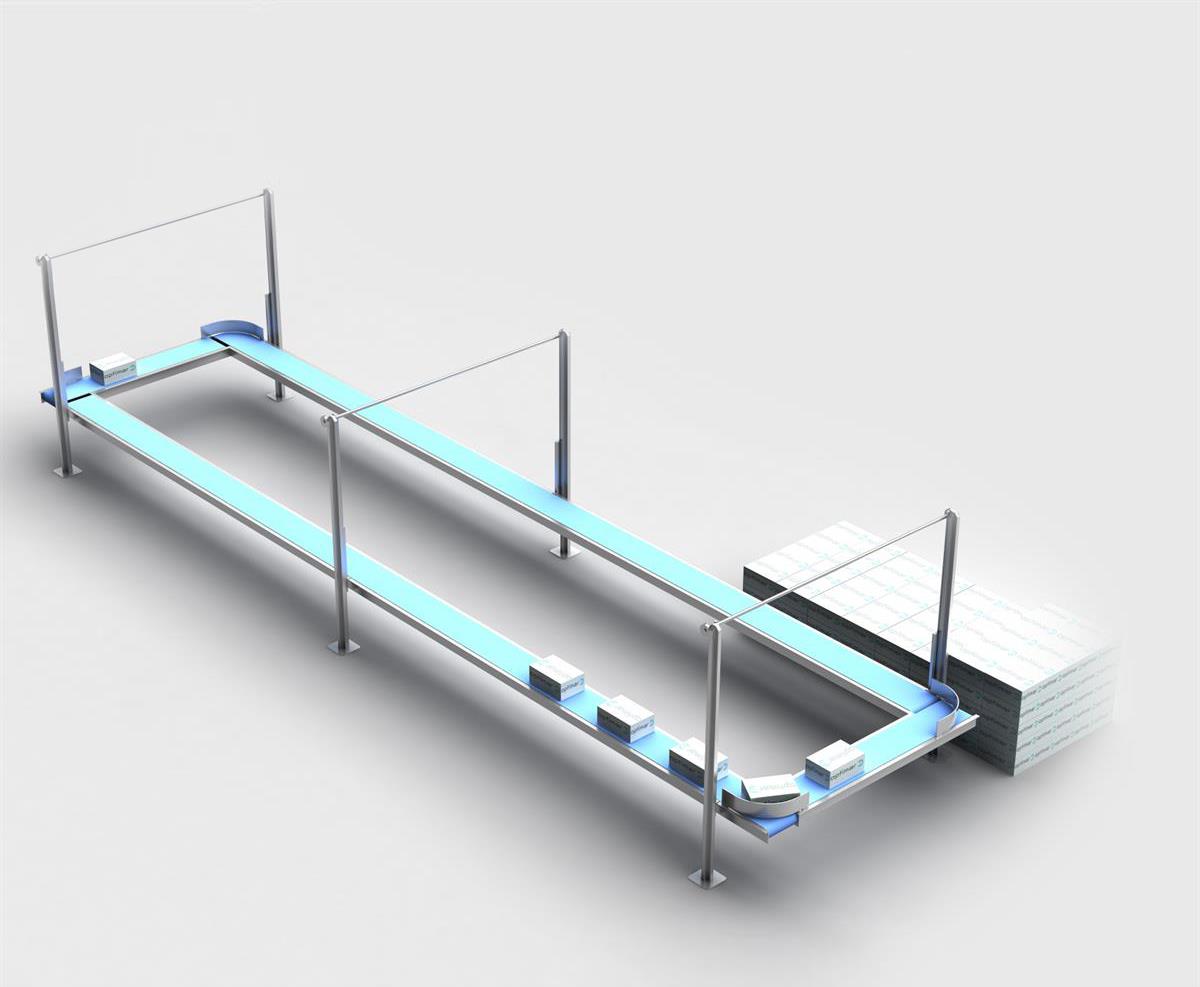

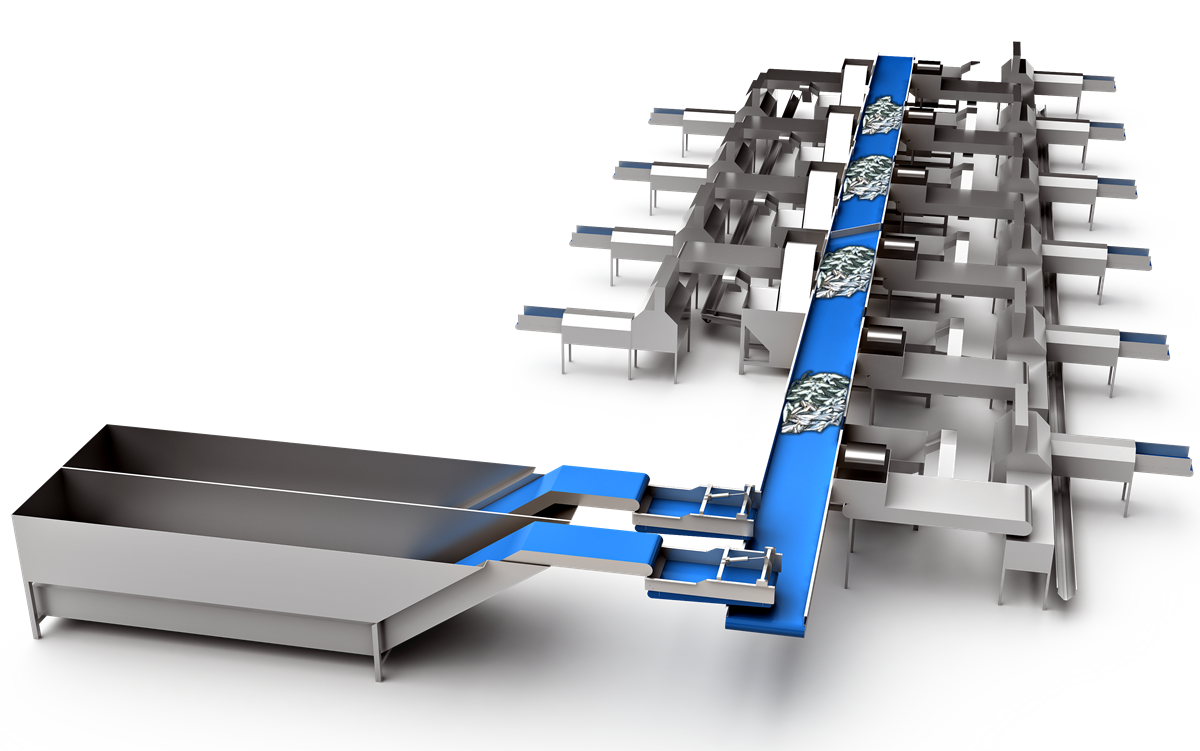

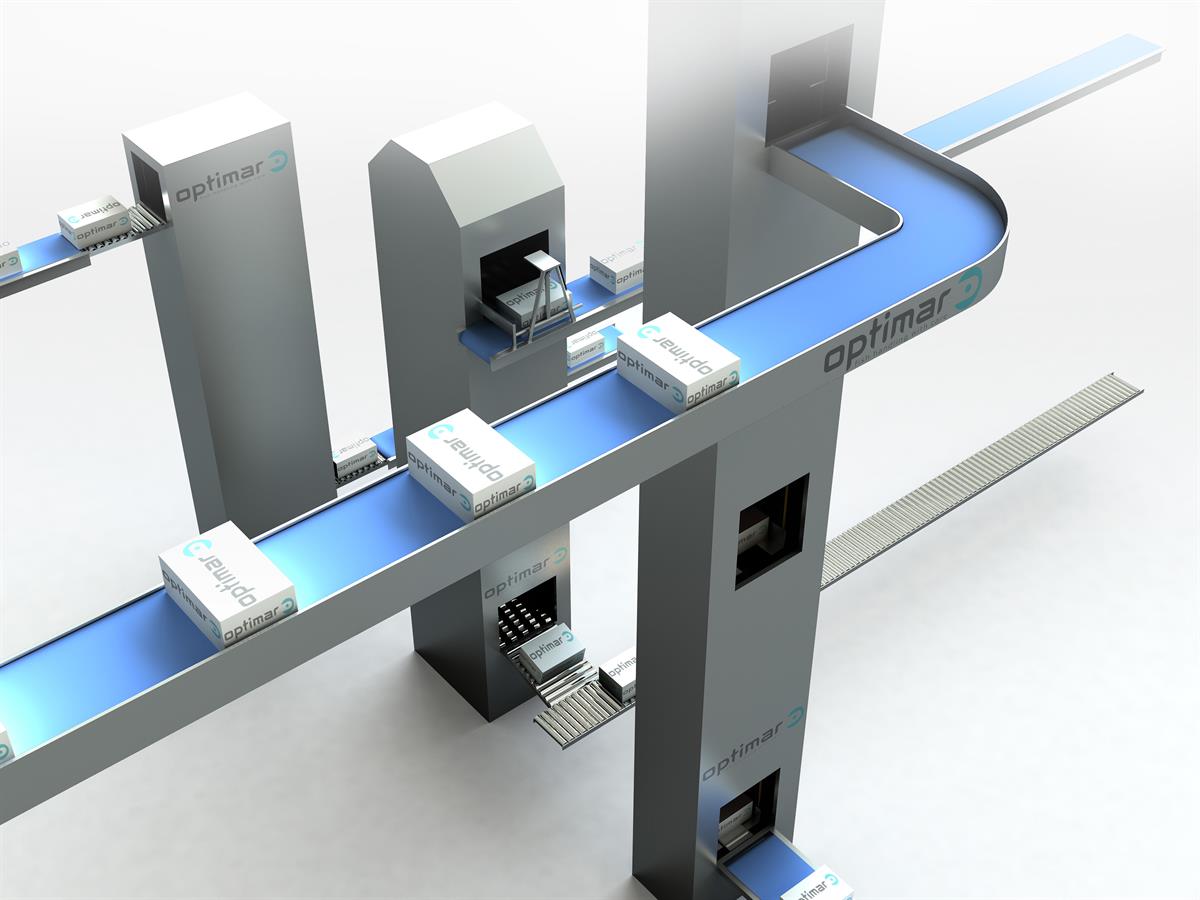

Conveying

Up, down,over, under, around and through

Optimar has made thousands of conveyors for use in all types of processes in all types of configurations in all types of production facilities. Seldom has one system been exactly the same as the next.

"One size" never "fits all"

The only thing “standard” about Optimar conveyors is that they move products from point A to point B. Beyond this basic function, however, something is always slightly different.

Virtually all Optimar conveyors are a customized combination of size, angle, movement, height, width and/or length. For Optimar – and for you – something as ordinary as a conveyor becomes quite extra-ordinary.

Conveyors are as vital to your processing system as the products they carry from one step to another. Each Optimar conveyor is designed to ensure a smooth, consistent product flow and, at the same time, conserve space and maximize efficiency.

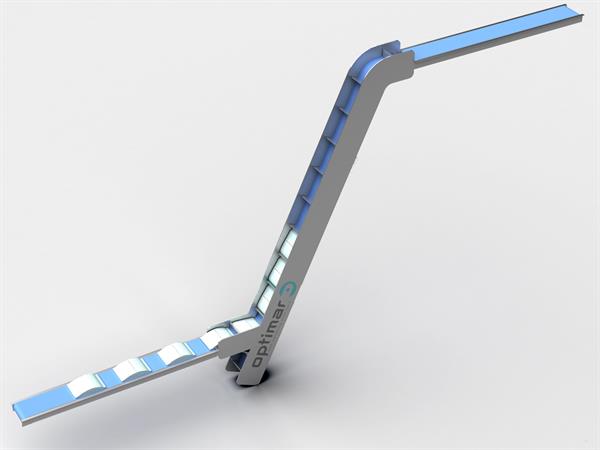

Elevator conveyor

Elevator conveyor

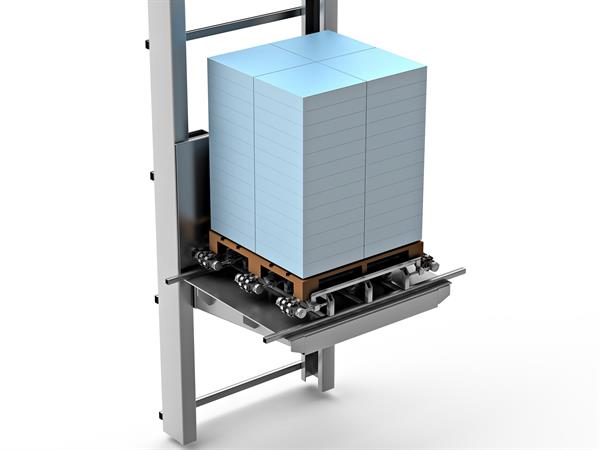

Pallet elevator

Pallet elevator Elevator

ElevatorFreezing

Seafood, vegetables, fruit juice

Whether a frozen block or box contains fish filets or Italian gelato, fruit juice or spinach, Optimar’s conveyor and palletizing systems handle it promptly and with care to ensure it remains frozen, pure and undamaged.

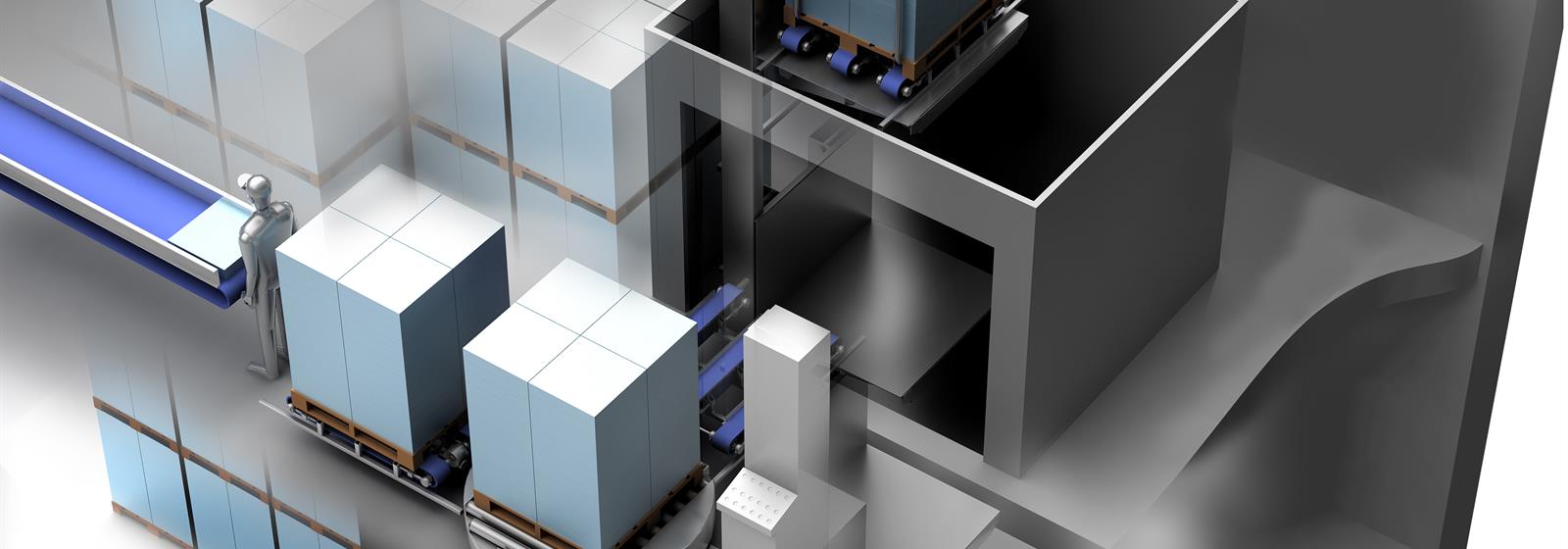

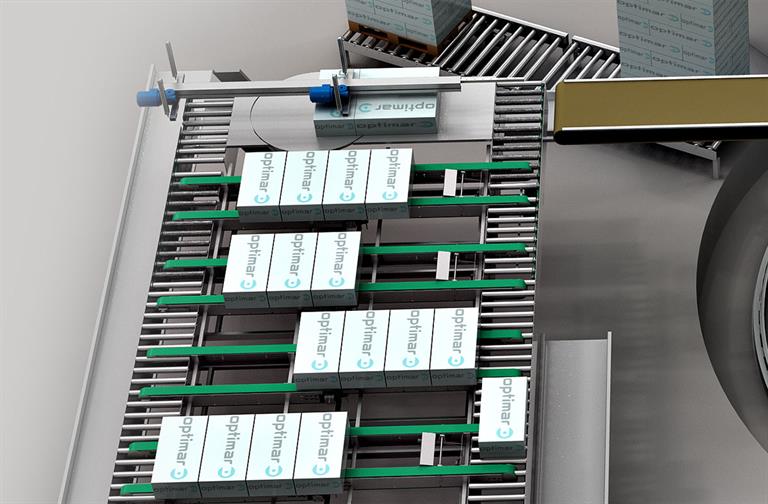

Palletizing from freezers

Optimar’s fully-automatic Palletizer eases each block or box onto its horizontal side and positions it on a special plate with other blocks in the pattern of the pallet layer. When the layer is complete, the plate gently glides the blocks onto the pallet then retracts to receive the blocks in the next layer. The pallet is lowered as it is fi lled layer-by-layer, eliminating the risk of dropping or bruising the block.

Wrapping stations are fully integrated into Optimar’s palletizing process but can be any type (turntable, rotary arm, etc.) from any manufacturer.

The fully-automatic, heavy-duty Palletizer handles any type of block, box or product. The palletizer shown here handles frozen vertical blocks weighing 25 kg (half blocks) or 50 kg (whole blocks).

Even at this pace it is so effictient it still:

- conserves space

- conserves energy

- conserves labor

Optimar’s semi-automatic version of the Palletizer was the first of its kind to be used onboard a ship for processing fish at sea. The system is extremely efficient when space is very limited and extremely cost-efficient when it is very expensive.

Special care for special products

Like its many other breakthroughs in freezing systems, OptiFreeze Blast proves, once again, that Optimar thinks “out of the box” even when it puts most of the technology inside one.

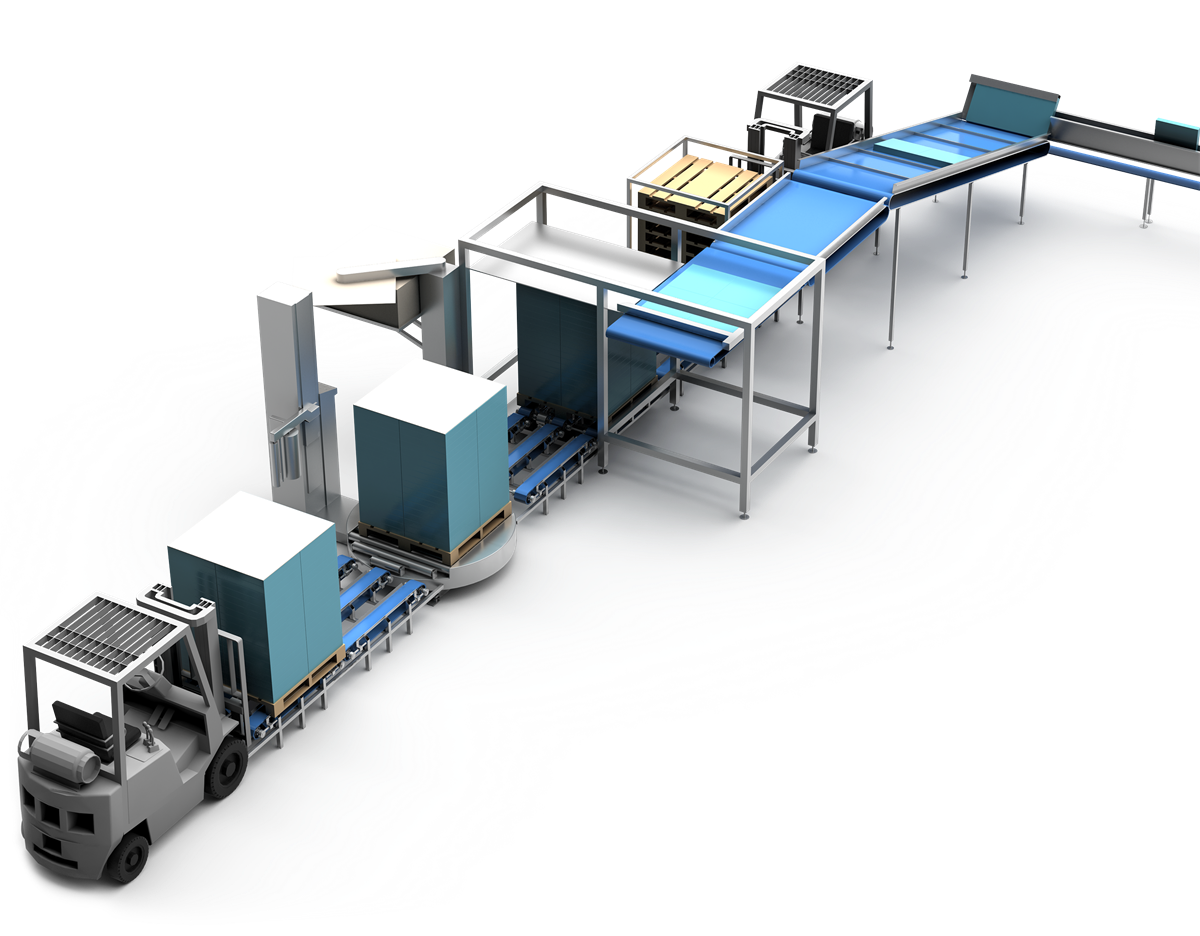

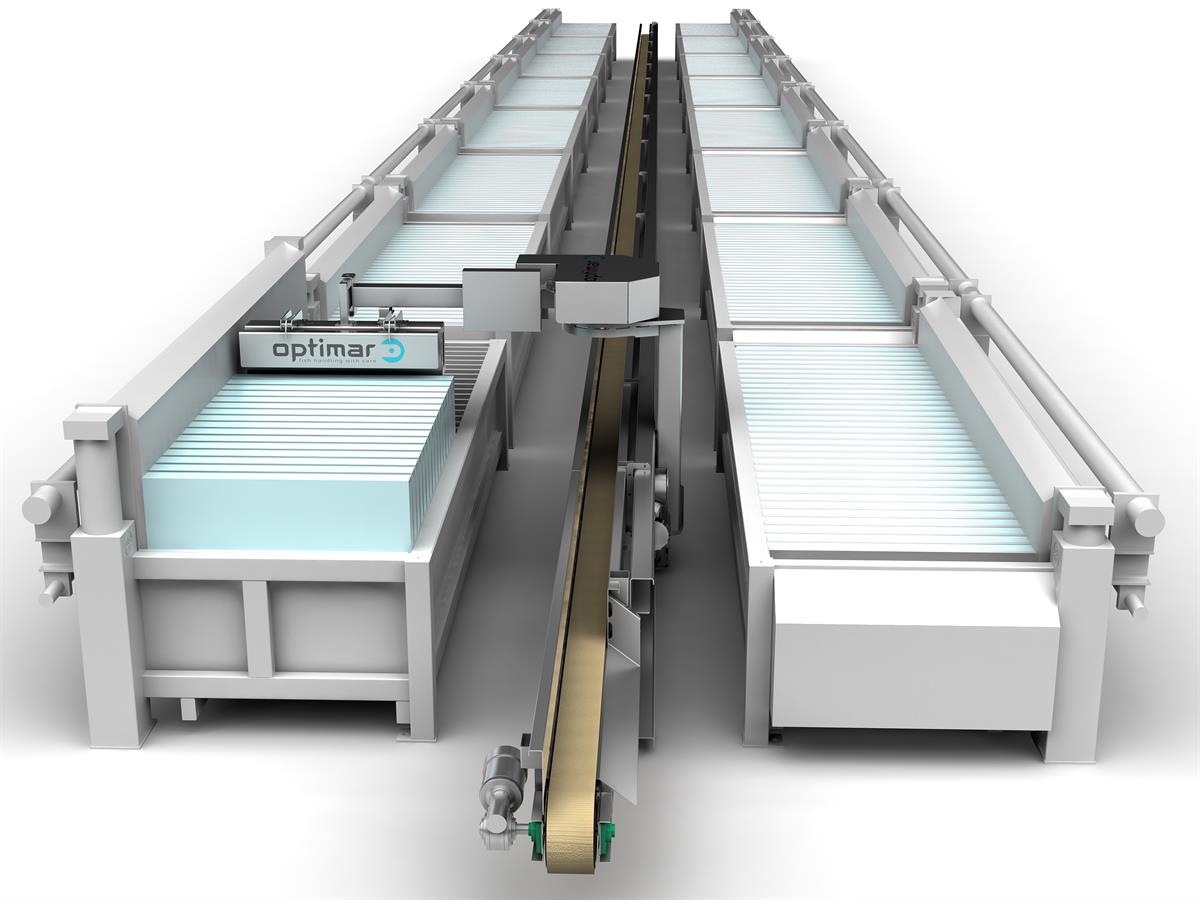

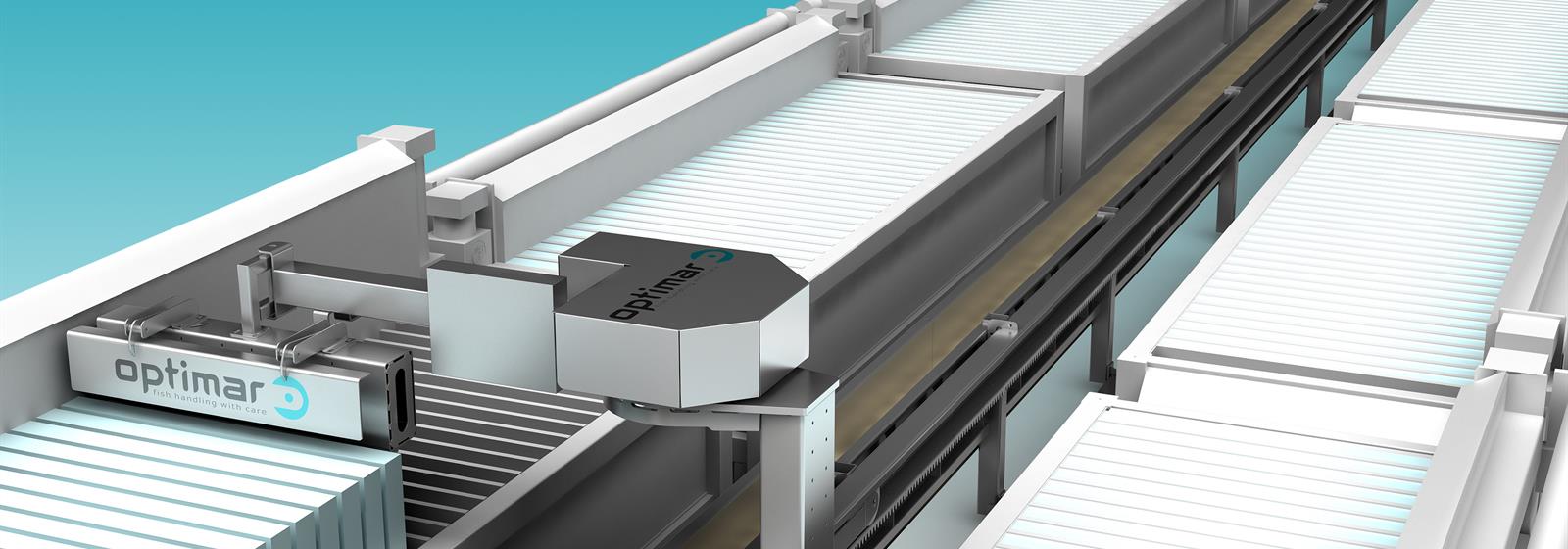

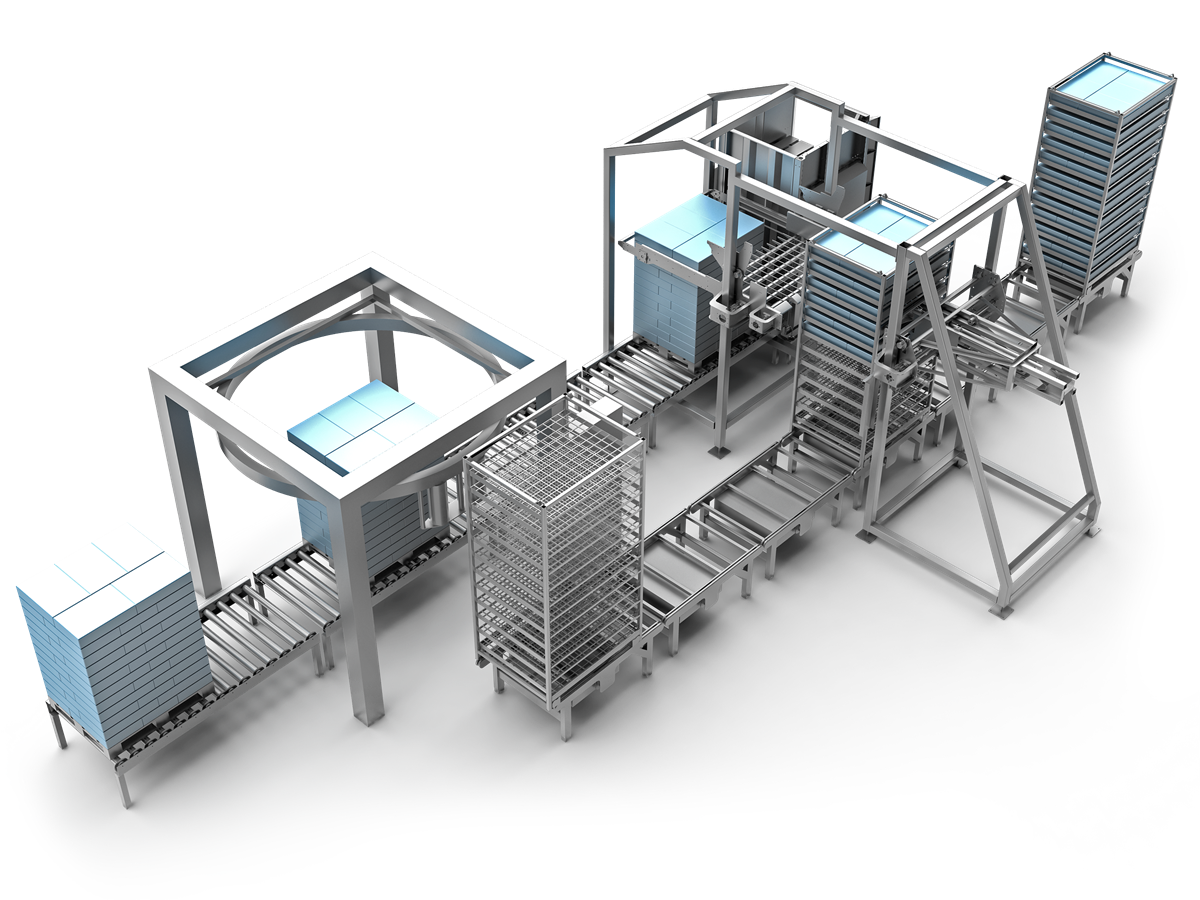

Blast is a fully automatic blast freezer where independent in-feed and out-feed systems create a significant logistical advantage.

The structural and operational designs for OptiFreeze Blast were first tested in experiments with SINTEF, the largest independent scientific research organization in Norway and Scandinavia. What started as a concept in theory is now a well-proven product in reality.

OptiFreeze Blast is at its competitive best when it processes high volumes of large, heavy products with long freezing times. Of course, its price per station and, thus, per product unit are just as low for high volumes of smaller, lighter products.

Whether the product being processed is as delicate as a hot dog bun, as tender as a steak or as slippery as a fish, Optimar works with you to design the trays, racks, packing and packaging systems required to ensure the integrity and quality of the end result.

Optimar has developed systems for freezing round trout so the skin surface remains unmarked. This product standard is especially important in Japan

There are lots of reasons why we keep our competitive edge and help you keep yours.

A gentle giant

As Optimar’s largest freezing system in size and capacity, OptiFreeze Blast is capable of freezing up to 1000 tons per day of any product – from meat and fish to poultry and pizza to vegetables and bakery goods.

For example, Blast has proven it can:

- reduce the area required for freezing by as much as 50%.

- eliminate manual labor and forklifts.

- reduce energy consumption and costs.

- reduce packaging costs.

- has flexible freezing times.

- improve health and safety in the work environment.

- contribute to improving the global environment.

- ensure product safety and hygiene.

- guarantee product quality.

What is surprising, however, is the gentle, special care with which each product is handled as it moves through this big, fully-automatic system. This is Optimar’s way of helping you ensure that the consumer receives the same undamaged, high-quality product you processed.

As unique as it is, OptiFreeze Blast is actually a typical Optimar system: a very special solution meeting very special needs in very special ways.

Unique designs

Optimar’s H1 and H2 horizontal freezers feature fully automatic technology that opens, loads and unloads only one station at a time. As simple and logical as this sounds, the design is unique to the industry with savings and benefits that are incredible.

Effective use of space

Uses 100% of available height

The fact that only one plate at a time is open can increase the cost-effective use of space by as much as 50%.

H1 and H2 freezers devote the full height of the space available to freezing. Unlike traditional systems, no extra space needs to be reserved for those times in the process when all stations must be fully open at the same time.

In addition, since the H1 and H2 are fully automatic, there are no loading or unloading height restrictions. The sky is really the limit.

Efficient freezing

Hydraulic equalizers maintain constant surface pressures, increasing freezing capacity up to 20%. Pressure on the content of a frame remains constant, regardless of the position of the station (lowest, highest or in between).

When a station is loaded and the plates closed, freezing is immediate, thorough and uniform. As a station is unloaded from one side it is reloaded from the other, saving time and conserving energy.

Energy efficient

Working strategically and automatically one station at a time maintains a continuous load level on the refrigeration equipment. This eliminates the energy-consuming spikes and temperature fluctuations caused by loading or unloading all stations of an entire freezer at the same time.

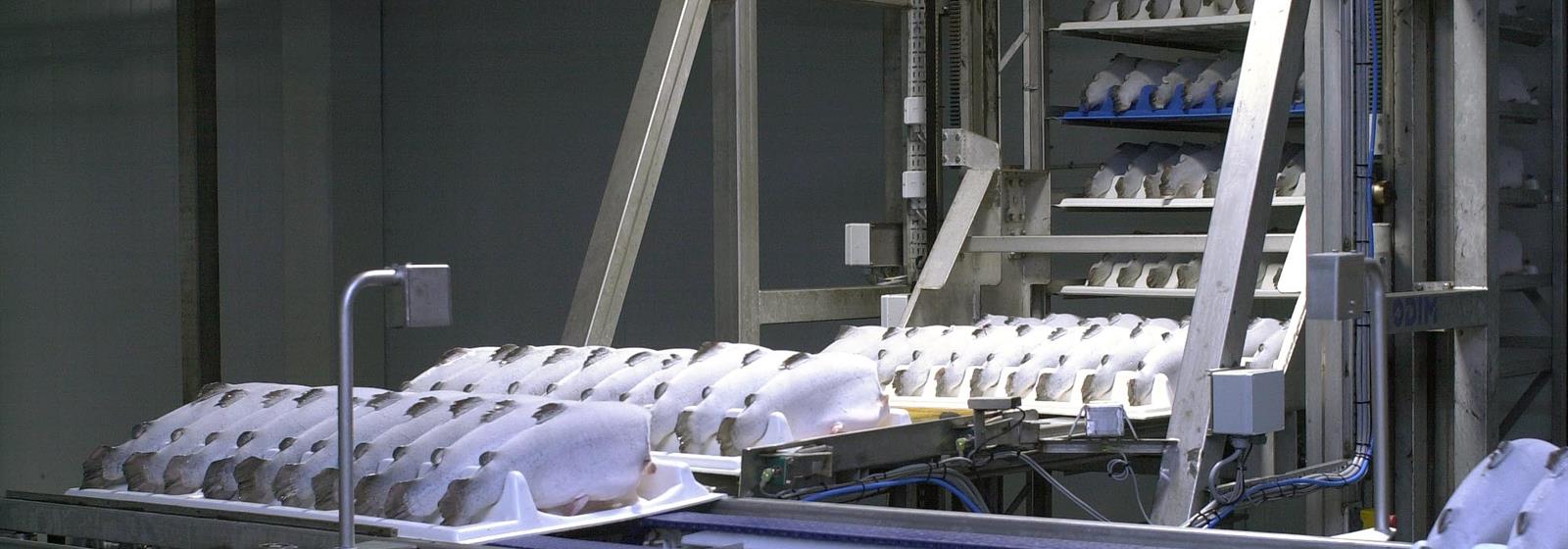

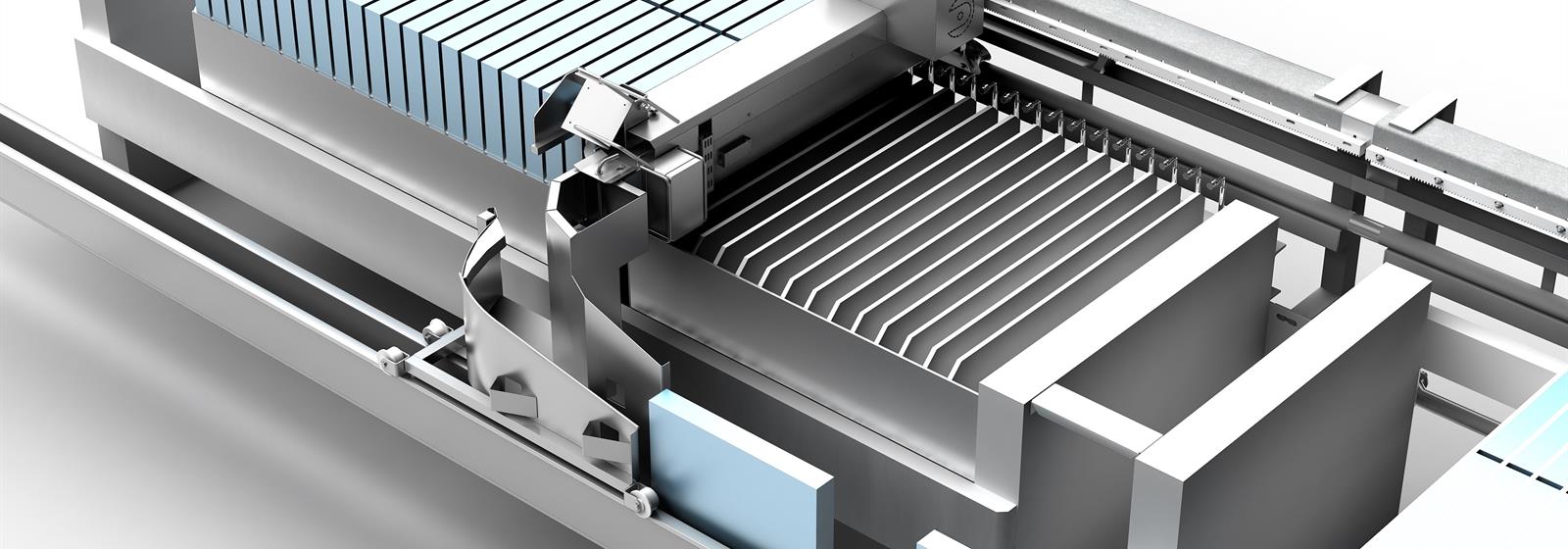

Automatic systems for vertical freezers

Optimar has several systems for unloading vertical freezers. Each has features that revolutionize the food processing industry.

Leading the way

For OptiFreeze, however, these unique features are simply basic standards:

- reliable and durable in all operating environments

- eliminate manual handling of heavy, cold loads

- operate at full potential in limited spaces

- ejector technology releases frozen blocks without warming, defrosting

- no risk of leakage

- off-loading conveyor takes very little space

All Optimar vertical-freezer solutions are designed to handle two half-blocks or one whole and transport them at heights above floor level that ensure safe and clean handling. Unlike most systems, the Optimar units can service an entire line of freezers rather than only one.

Each of the systems is designed to be installed wherever a person can stand. They require no extra ceiling height, for example, and they can easily be positioned to handle space limitations caused by pillars, bulkheads or other equipment.

Optimar’s unloading solutions for vertical freezers eliminate the use of electrical sensors that areoften unreliable in extremely cold environments.The unloading units are separate from the freezer, however, so freezing can continue if the unloader is down.

V1

Fully automatic side-ejection system. Requires compatible vertical plate freezers.

V2

Semi-automatic side ejection system. Requires compatible vertical plate freezers.

V3

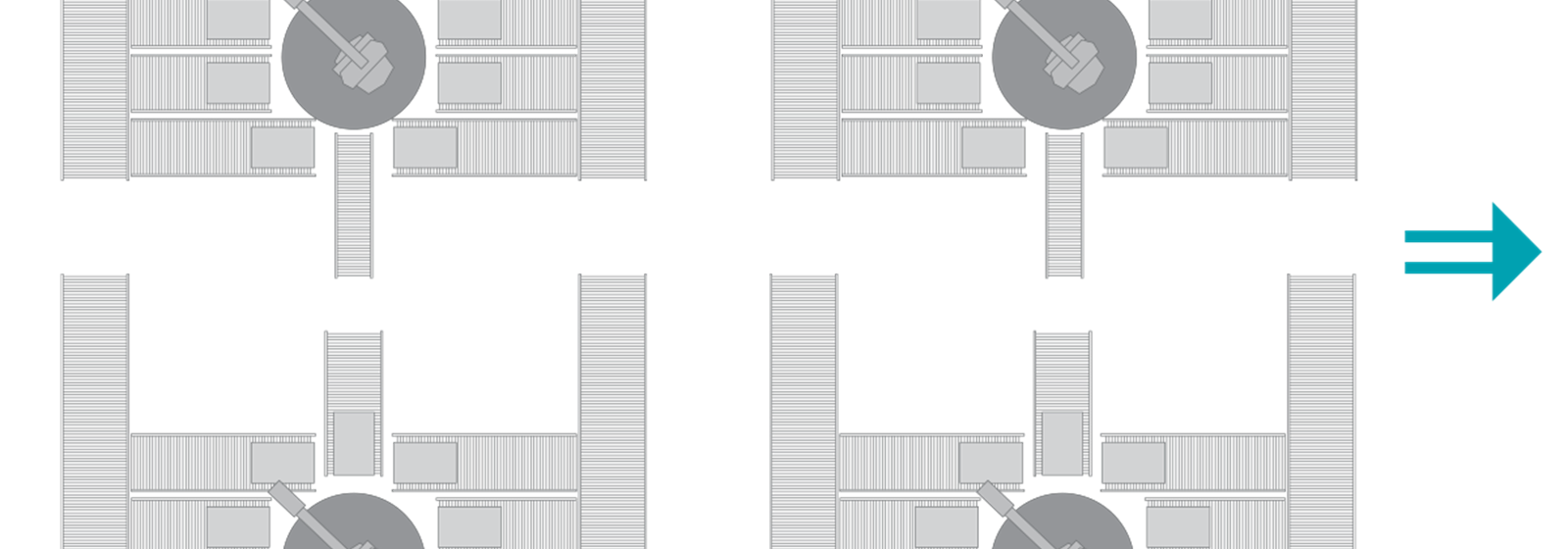

Fully-automatic unloading system using one robotic arm to off-load blocks (two halves or one whole) from two freezer lines. The robotic arm can move along the lines in either direction and can be used with any standard vertical plate freezers.

One success leads to another

Optimar’s goal has always been to continuously improve our products so you can improve your food processing efficiency, safety and profitability.

We use the experience and expertise we gain by successfully solving one challenge to confront and overcome another. As a result, we develop solutions that lead the way in design, technology, handling and capacity.

Example: 36 freezers positioned in four lines of nine freezers each.

Again...

In 2003, Optimar developed the first fully automatic vertical unloading system for use on board a ship. One automated unloader can service an entire line of freezers placed in a row of any length.

36 OptiFreeze-compatible freezers

NOK 14.4 million

4 unloading units (one per line)

NOK 2.6 million

Total cost: NOK 17.0 million

And again...

In 2005, Optimar developed a semi-automatic version of the fully automatic vertical unloading system. The modified system still eliminates manual handling of heavy loads and services the same number of freezers in the same alignment but substantially reduces the price.

36 OptiFreeze-compatible freezers

NOK 9.9 million

4 unloading units (one per line)

NOK 2.6 million

Total cost: NOK 12.5 million

And again...

In 2008, Optimar released a fully automatic robotic system to unload vertical freezers. One robotic arm services two lines and can be used with any standard freezer. This makes it the perfect solution for upgrading an existing processing facility, on board or on shore. For example, two robotic arms can service four lines of freezers, in theory up to any number in length.

36 standard freezers in an existing plant

NOK 0.0 million

2 unloading robotic-arm units

NOK 3.0 million

Total cost: NOK 3.0 million

Automatic plate freezers

Optimar’s automated vertical and horizontal plate-freezing systems are available in a variety of types, sizes and capacities but all solutions offer the same major benefits

Safe, healthy work environment

OptiFreeze solutions eliminate:

- prolonged, repeated exposure to cold, humid air.

- manual lifting of heavy, hard-to-handle frozen blocks.

- repetitive, difficult movement in limited spaces.

Site hygiene and satisfied consumers

OptiFreeze stainless steel, non-corrosive frames, hoses and plates ensure:

- easy cleaning, sanitizing and maintenance.

- steady, uniform temperatures throughout the processing cycle.

- gentle handling to prevent product damage (bruising, staining, breaking, defrosting, etc.).

Increased productivity and profitability

OptiFreeze solutions are cost-effective from the start:

- high-performance units independent of new or existing refrigeration systems.

- durable and reliable even in the toughest conditions at sea or on shore.

- back-up plans are always in place to ensure a steady workflow.

- interface with all types of coolants, including those safest for the global environment.

- easier to recruit and retain labor.

All OptiFreeze systems may be monitored and managed using OptiControl NetCenter:

- provide real-time data regarding capacity, input, output, etc.

- exchange up-to-the-minute information via the Internet.

- provide real-time data regarding capacity, input, output, etc.

- exchange up-to-the-minute information via the Internet.

Stop! back-breaking, heavy lifting

Stop! back-breaking, heavy lifting

Start! increasing efficiency, capacity, profitability

Palletizing

State-of-the-future not just state-of-the-art

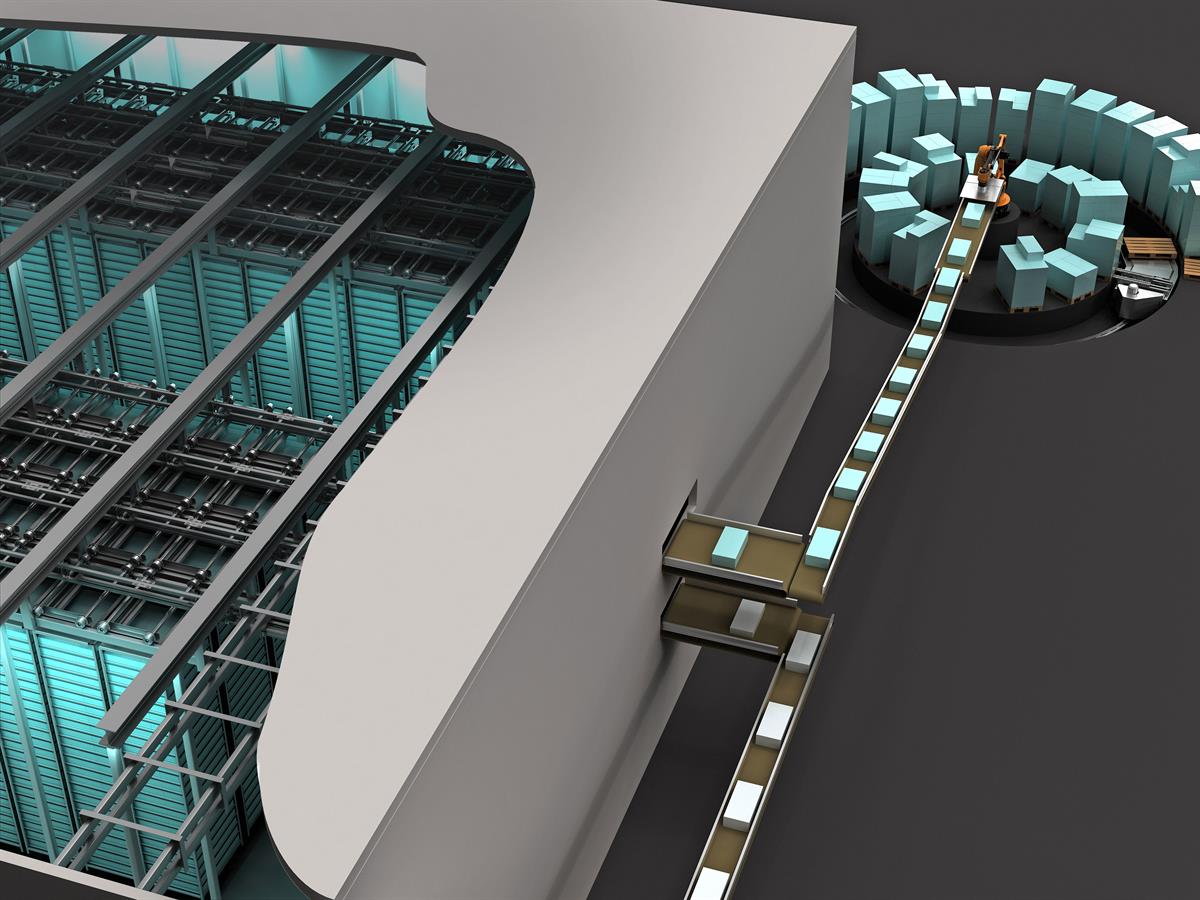

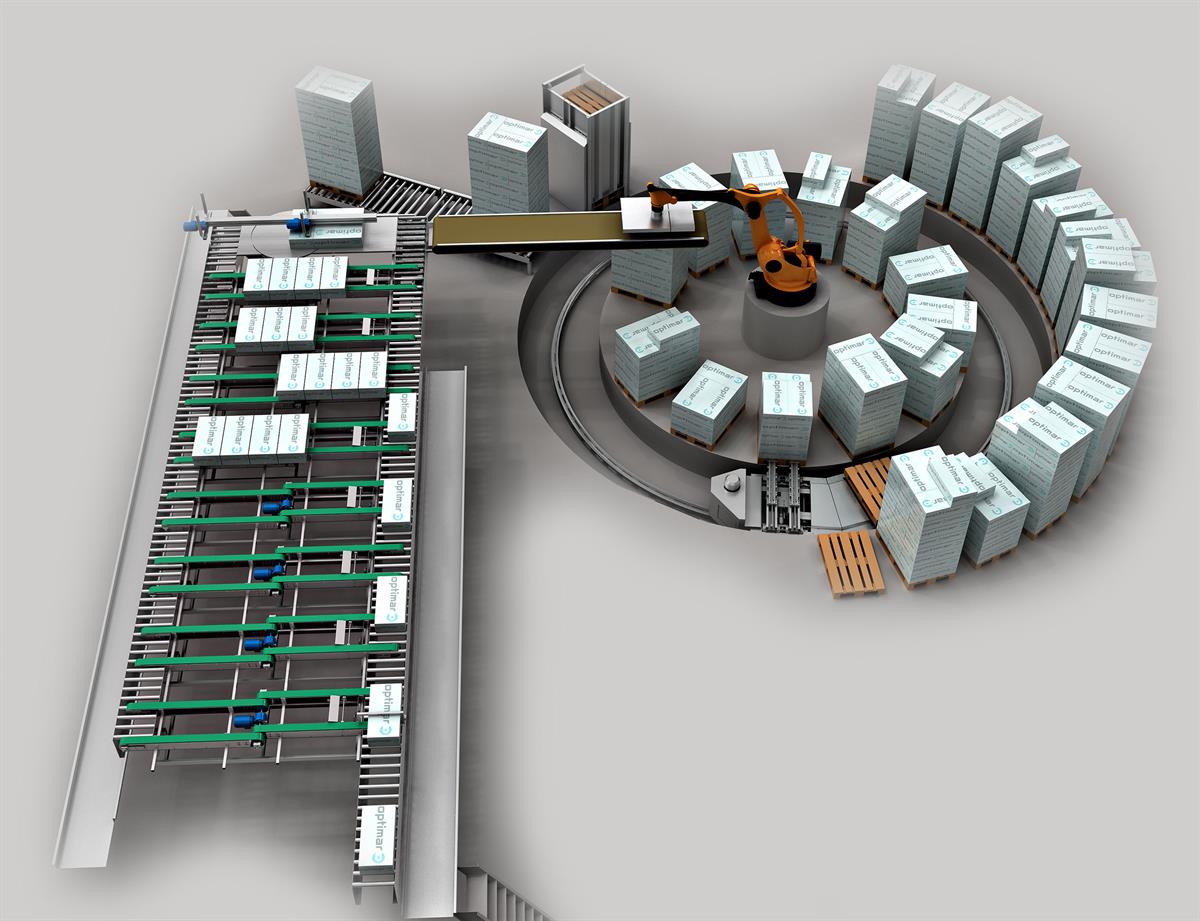

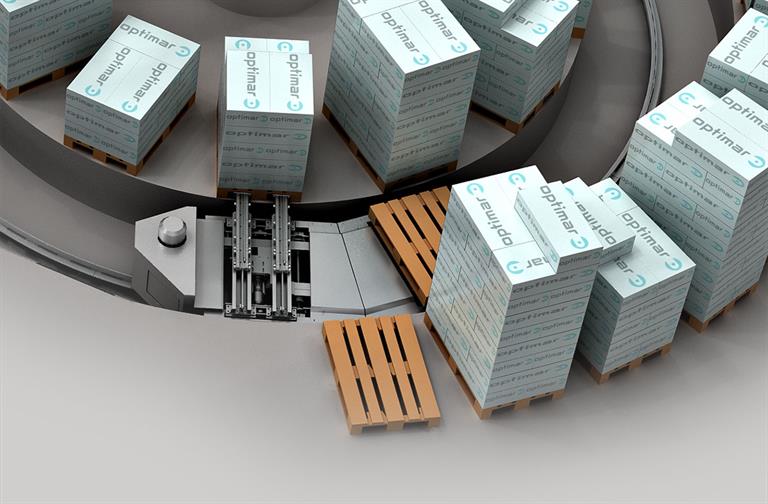

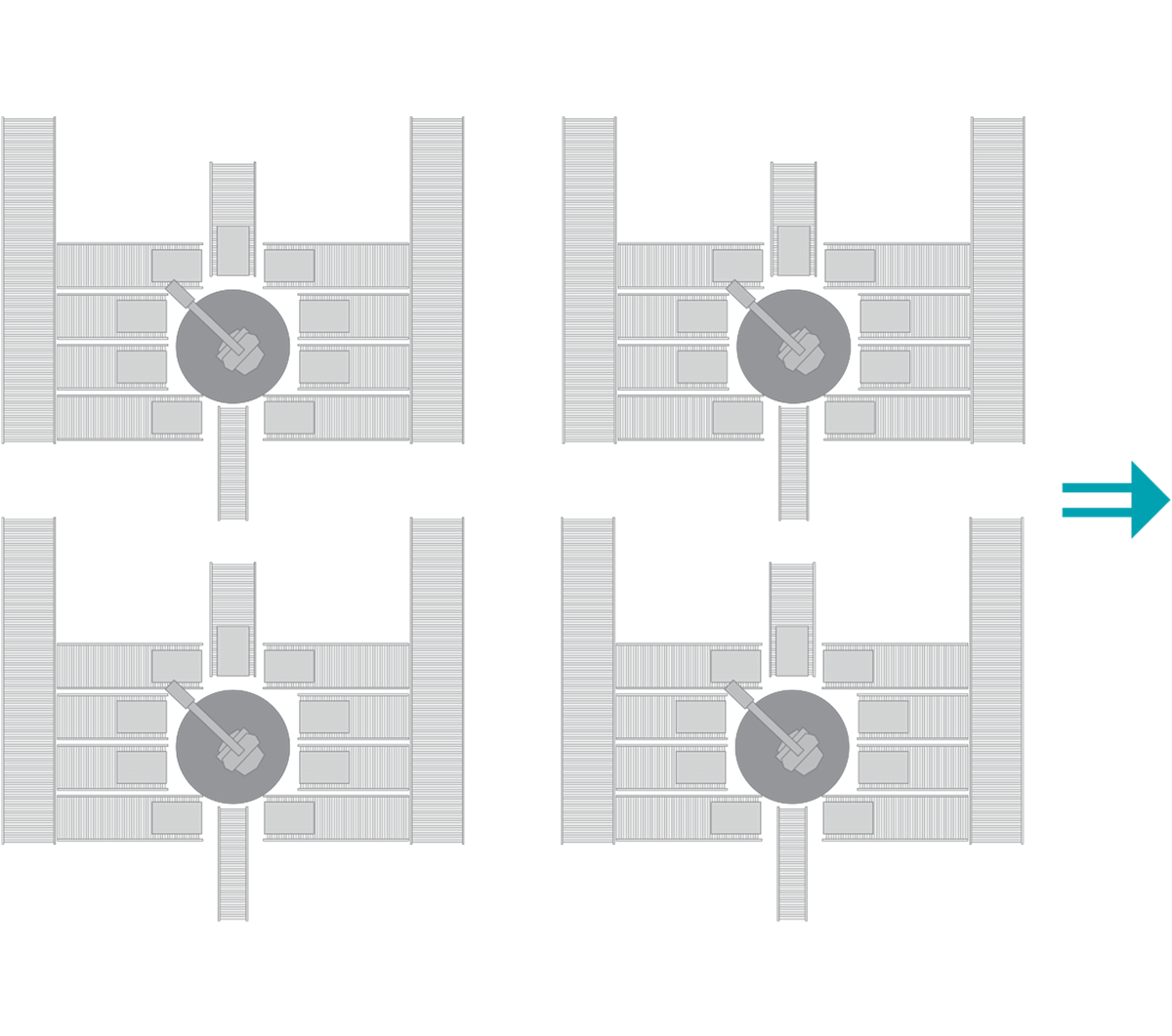

The robotic arm may be the most distinctive feature of Optimar’s unique circular palletizing center but it is only the most visible part of a continuous, fully automatic, total system.

.tmb-xl-narrow.jpg?sfvrsn=ee96fcd0_3)

Circular Palletizing Center

The robot may be powerful, fast and hard working – it is definitely each of these – but its impressive actions depend on the control programs that carefully manage the conveyor and sensor systems, define the timing and direct the packaging decisions the robot executes.

The result of these intricately coordinated efforts is a fully automated palletizing center unsurpassed in design, capacity, power and efficiency.

The Optimar Circular Palletizing center:

- sorts and loads up to 40 pallets according to product type, quality, quantity, weight, special order, etc.

- handles up to 30 boxes per minute.

- loads box-by-box or layer-by-layer.

- uses common-sense to position pallets.

- significantly reduces space required for loading, handling, off-loading.

- easy to operate.

Optimar’s Circular Palletizing Center is a modular system. You can start with the basics – a conveyor and a robot – and gradually expand the system as your needs change. The Circular Center is so time- and cost-effective it won’t take long before what you have won’t be enough.

Sophisticated, robust, efficient

A robot is only as “smart” as the program running it. Optimar’s team works to make yours the very best.

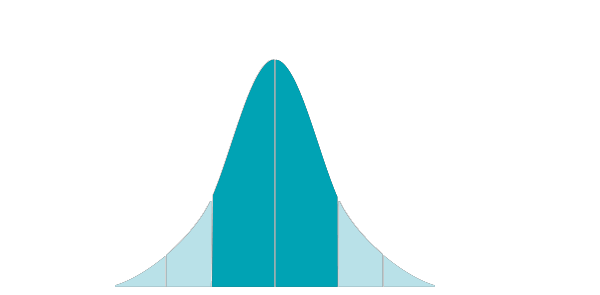

The center of activity

Optimar’s control system uses common sense or, more technically, the statistics of a normal “bell curve” to position pallets around the robot. Since the robot handles the most common product type most often, these pallets are placed closest to the robot’s pick-up point. This minimizes the time and distance the robot uses for the most repeated movement.

Similarly, pallets for less common product categories are placed symmetrically, side to side, around the circle until pallets for the least common items, the extremes of the curve, are in positions furthest from the pick-up point.

In-feed conveyor and buffer

The standard conveyor system feeding the robot can be expanded to provide a temporary storage area where small quantities of less common product types can be collected and held until the pallet from the outer circle is in position.

A booster speeds up handling by preparing a full layer of cartons for the robot to grasp and place on a pallet. The control system keeps track of the layering scheme so the robot automatically turns the layer to ensure the load on the receiving pallet remains stable and well-balanced.

The control system together with the temporary storage synchronizes the workflow, ensuring the robot always has products and pallets to load.

Pallet trolley

Synchronized with all the other action, the control system moves a two-bed trolley around the outside of the palletizing circle to pick-up a full pallet and replace it with one that is empty or, when the time is right, a pallet from the outer ring of less common product types.

A full pallet that is ready for shipping is moved out of the palletizing area while a pallet only partially filled with a special product type may be moved back to the outer circle waiting area until the control system determines there are, once again, enough boxes in the buffer to bring the pallet forward for further loading.

Outer circle

Optimar’s unique outer-circle concept significantly expands the capacity of the Palletizing Center, providing the option of handling up to nearly 30 pallets more than just the basic stations of the inner circle.

The outer circle serves as a holding area for partially filled pallets of less common products that may be sorted by type, weight, quality, quantity, content, etc. The palletizing control system determines when enough boxes of a certain type have been set aside in intermediate storage and can be loaded efficiently onto the corresponding pallet in the outer circle without interrupting the workflow.

We run circles around the competition

Replace up to 4 conventional traditional systems with only 1 Optimar Circular Palletizing Center.

Traditional robotic palletizing

- requires complex distribution logistics

- services at most 8 active palletizing stations per robot

- requires one inactive position to store empty pallets

- handles only one box at a time

- handles at most 8 to 10 boxes per minute

- wastes robot’s capacity in order to handle empty pallets

Optimar’s Circular Palletizing Center

.tmb-lg.jpg?sfvrsn=ee96fcd0_1)

- robot dedicated to only one task – palletizing

- handles up to 40 pallets of different products

- loads box-by-box or layer-by-layer

- handles up to 30 boxes per minute

- conserves space and energy

- robust and reliable

- easy logistics to and from palletizer

Beyond the basics

The fully automatic Rack Palletizer is designed to unload the racks that the OptiSpecials Rack Loader fills. It is designed to handle very heavy loads very efficiently – up to 60 tons per hour.

Automatic palletizing from racks

In addition to its standard single - and double- push shelf-ejection systems, Optimar offers a unique triple-push ejection option – the only available system of its type with a track record of reliability proven by years of daily use.

A touch-screen control panel makes it quick and easy to adjust the Palletizer to handle racks of different heights or to change the height of the pallet stack (10, 12 or 14 layers for example). Depending on the number of shelves in a rack, the number of shelves ejected at one time, and the number of layers in a pallet, the Optimar Rack Palletizer is capable of handling up to 60 tons per hour.

To ensure heavy-duty durability and dependability in extreme environments, the Palletizer uses hydraulic actuators. Although designed as a complete system, including conveyors and a plastic wrapping machine, the units of the Rack Palletizer are modular and can be adapted to fi t most existing processing facilities. The Palletizer can potentially reduce the labor force by 10 to 12 people.

Any product on any pallet

Whether loading box-by-box or layer-by-layer, one pallet at a time or 40 at the same time, Optimar has a palletizing system to meet your needs.

We can do it!

Since even our basic systems far exceed the criteria generally considered “standard” by others, you will soon see why it is perhaps most accurate to say, “we have a customized solution just for you.”

Our background in handling frozen products that are heavy (like a rock) and slippery (like a fish) has helped us develop systems that have incredible power applied so carefully the product is not damaged. We have perfected a few other features too.

OptiPall systems are:

- able to tolerate extreme temperatures, vibration, moisture, etc.

- modular solutions that can be adapted to a wide range of specific products: light or heavy, fresh or frozen, soft or firm, etc.

Optimar takes hands-on care of every part of its unloading and palletizing systems, whether hardware, software, mechanical or control components. They can be serviced via the Internet and easily interfaced with OptiControl NetCenter.

Service

Beyond the call of duty?

"Optimar can’t help you avoid a catastrophe, but they CAN help you recover in record time!" Read more testimonials...

Optimar customers know our machines work in extreme conditions ? they know we do too!

Just as a ship was docking in the calm summer waters of a port in South America, a container ship carrying new Optimar equipment destined to update the vessel encountered the brutal winter conditions of the North Sea. The ship and crew survived the turbulence further north but many containers were lost or damaged, including those holding Optimar’s automated onboard-processing systems built specifically to modernize the ship in the south.

“We assumed the vessel would be out of commission for a full season,” recalls Hitoshi Aita, president of EMDEPES s.a Chile that owns the ship. “This would have meant a tremendous loss of time and income.

“Fortunately,” says Mr. Aita, “Optimar disagreed. They promised to have the vessel up and ready just weeks after the original schedule, something we thought was a ‘mission impossible’ given the time and distance. However, Optimar came through and the ship in South America left the harbor with a fully operational state-of-the-art onboard fish processing plant only fourteen days after the originally scheduled launch date.”

“I was very impressed that a company close to the Artic Circle could re-deliver the equipment to a shipyard in Chile within the given timeframe,” concludes Mr. Aita.

Prompt deliver to the most remote spots

A long-liner fishing vessel enroute from New Zealand needed critical parts for its onboard loading and unloading elevators in order to continue its extended working voyage. Optimar’s first challenge was to machine the parts as quickly as possible. The second and greater challenge was to get the parts to the vessel. The ship’s captain determined that the parts should rendezvous with the ship at the port closest to the point where the ship encountered the mechanical problems. It was vital that the parts be in port and ready for installation the moment the ship docked.

The port of destination was St. Helena, a remote island in the southern Atlantic midway between Africa and South America. The island, a British colony until 1981, is most famous for the fact that Napoleon was detained there from 1815 until his death. For Optimar, an even more important fact was that the island had no airport and was itself accessible only by the Royal Mail Ship, sailing at intervals from Cape Town, Walvis or Ascension Island.

The parts took the most direct air and sea routes possible and arrived in St. Helena well ahead of the vessel. Half a world and ocean away, Optimar delivered the order with the same precision it made the parts.

Shipping address:

The Island of St. Helena South Atlantic Ocean

Coordinates:

15o57”S, 5o42”W

Population:

4255

Area:

420 sq. km

Optimar can’t help you avoid a catastrophe but we can help you recover in record time

In November 2007, at the peak of the fishing season, a fire in an electrical cable-trace at the Norway Pelagic factory in Bodø, Norway, stopped the entire factory and caused considerable damage to the processing equipment.

Before the ashes were cold – and that doesn’t take long above the Artic Circle – it was clear that the process of putting out the fire had caused a strange chemical reaction that left all the stainless steel equipment covered with acid spots.

Fortunately, there were no injuries but with the holiday season approaching the loss of time and income for the employees as well as the company was as damaging as the loss of the machines.

When Optimar was called for advice, technicians were on site immediately, assessing the damage and determining what to replace and rebuild to get the company up and running as quickly as possible.

With round-the-clock, well-coordinated efforts by Optimar’s production and service teams, Norway Pelagic’s own crews and local suppliers, Norway Pelagic celebrated the new year in a fresh, clean, rebuilt facility – less than a month after Optimar received the emergency call for help.

Prevent a minor problem from becoming a major crisis

No matter how good your Optimar equipment is – and we think it is the best – problems can and will occur, especially when it is run at full capacity in extreme conditions in even more extreme environments.

We can’t predict everything that might happen or when, but that doesn’t keep us from being proactive in trying to prevent unplanned downtime and production surprises.

Based on our accumulated histories and expertise, OptiService has developed preventive maintenance schedules for all Optimar equipment, from the most basic conveyor to the most sophisticated robot.

All newer Optimar machines, for example, are equipped with software that monitors the operating time and parts that should be serviced or changed accordingly. Just like a car, each machine requires different levels of maintenance at different timesdepending upon factors such as the intensity of the work load and the products being handled.

Without preventive maintenance, the risks for fatal failure, spoiled products and, as a result, the costs for lost production increase dramatically. We don’t want to take that risk and we don’t want you to take it either.

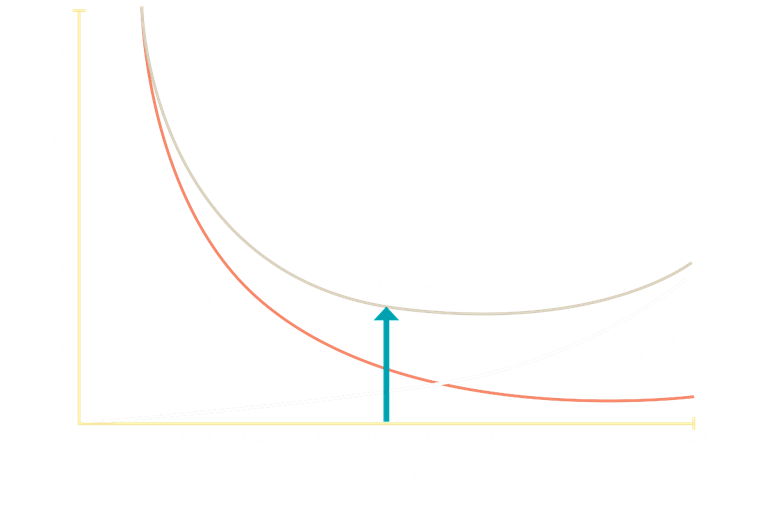

Replace a part before it fails or after?

It may be hard to believe but preventive maintenance leads to significant short- and long-term savings. Numerous studies and real-life histories show that preventive maintenance:

- improves system reliability

- decreases cost of replacement

- decreases downtime

- improves management of spare parts inventory

An OptiService Agreement is as durable and reliable as all Optimar products. We work closely with you to keep your Agreements up-to-date and functioning as well as the equipment they protect.

OptiService works very hard to strike a balance between your risk – the cost associated with a failure – and the time between preventive maintenance visits.

When equipment doesn’t work the product doesn’t flow and neither does your profit.

Components that wear out are candidates for preventive maintenance. When the cost to repair or replace a component before it fails is less than the cost to replace the component after it fails, it makes sense to maintain the component preventively.

Source: Reliability HotWire, issue 96, February 2009

Comprehensive, reliable, guaranteed

Optimar’s innovative service plans are designed to ensure you stay up and running or quickly recover if you aren’t.

.tmb-xl-narrow.jpg?sfvrsn=349bfcd0_3)

OptiService Agreement

Each agreement is tailor-made to ensure that the right service options are combined in ways that best match your specific processing needs. All agreements, however, are based on Optimar’s fundamental guarantee:

Details in an OptiService Agreement may vary according to the type of production, the location of the facility, the level of automation and technology, the use of new and existing equipment, and even the current activities of your closest competitors.

Optimar applies the same creative problem-solving approaches to its service agreements as it does to each of its products and each of your challenges. The results are what set us apart:

- Spare-parts leasing programs.

- Price guarantees.

- Online webshop for one-stop spare-parts ordering or browsing.

- Remote diagnosis and resolution of a problem by phone and/or Internet.

- Individualized preventive maintenance plans.

- Notification of changes in local, national or international regulations or standards.

- Analysis of existing equipment to upgrade, relocate or replace.

- Operator training.

An OptiService Agreement is as durable and reliable as all Optimar products. We work closely with you to keep your Agreements up-to-date and functioning as well as the equipment they protect.

Any part, any time, any place

It is not unusual for a supplier of small- or large-scale equipment, like Optimar, to include a spare-parts package of components in a product delivery.

It is very unusual, however, for you to have theopportunity to specify the contents of the package.

It is even more unusual for you to have the opportunity to lease the package and pay for a part only when you use it.

Whether this week, this month or this year, you pay for parts only as you use them.

Full-time service from a full-time partner

Optimar is itself a full service team and OptiService is a vital player from the very beginning. The way we play the game, however, there is no final whistle – we’re here to stay and to help you at a moment’s notice.

These are facts-of-life in the processing industry and Optimar takes them as seriously as you do.

These are the reasons why OptiService is a well-defined Optimar product and, like all our products, one we stand behind long before and even longer after your purchase is complete.

Our service technicians have hands-on, real-life, real-time experience with everything we supply; from conveyors, freezers and palletizers to the nuts, bolts and gaskets that hold them together to the software that controls them.

Optimar’s designers, system engineers and sales representatives not only recognize the value of this practical experience, they depend on it. They work just as closely with our service staff as they do with you to determine the best ways to meet your needs and requirements.

Fact

At one time or another, every penny of your profit passes on, to or through the Optimar equipment you own.

Fact

Whether you are processing fish, chicken, spinach or hot dog buns, time and timing are critical factors to ensure freshness, quality and consumer health.

Fact

Downtime is not an option!