HOW DOES IT WORK

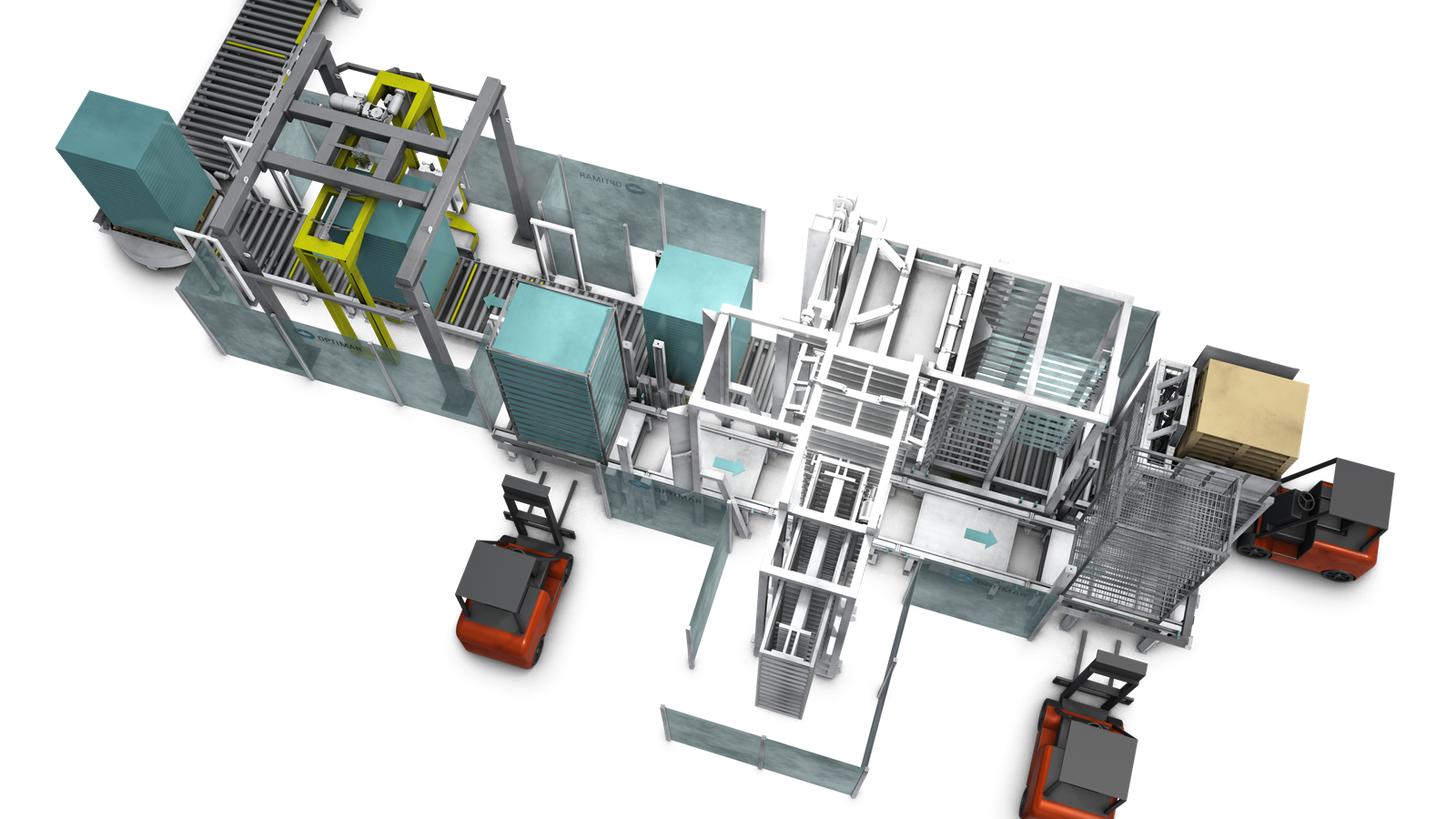

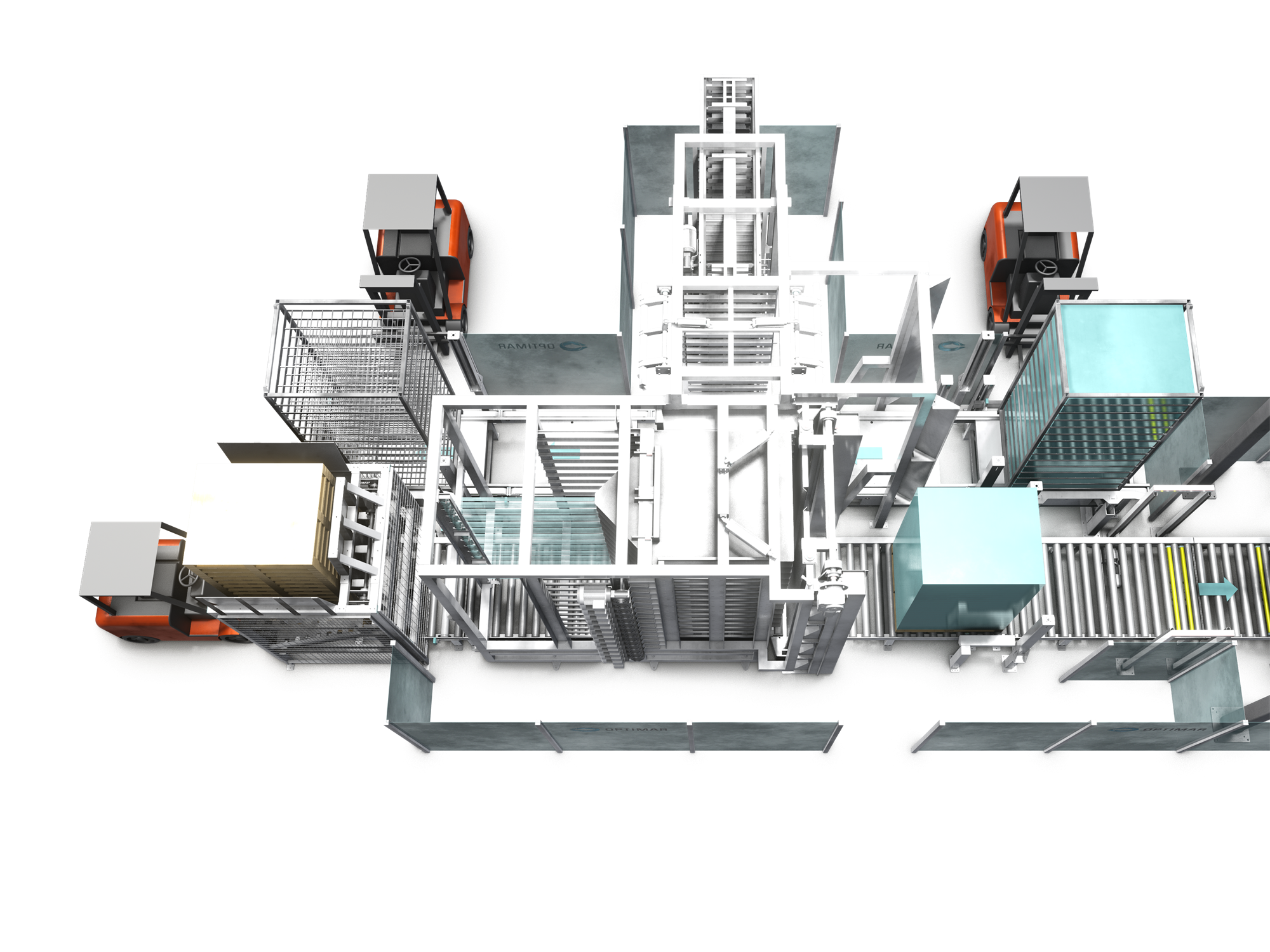

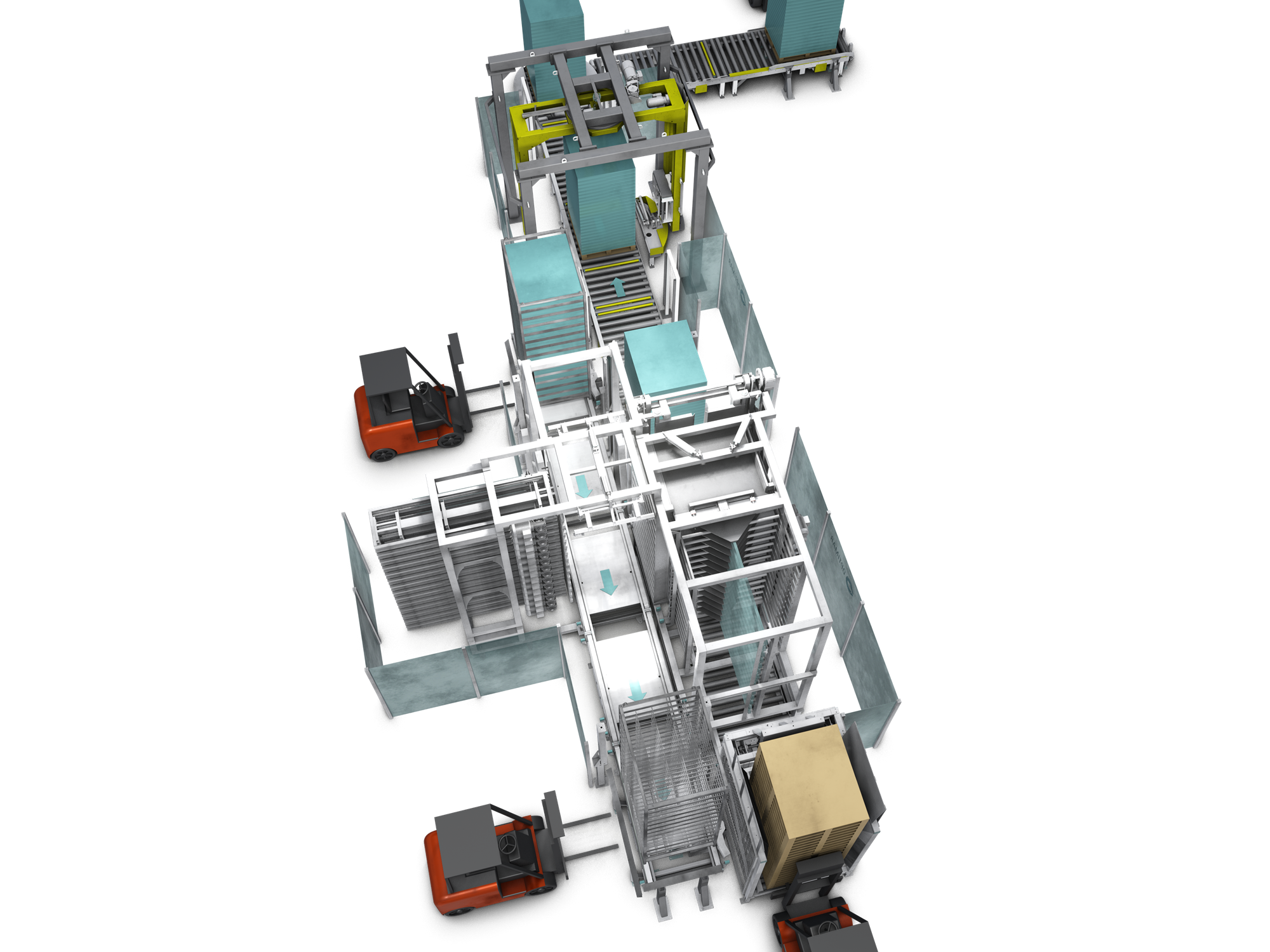

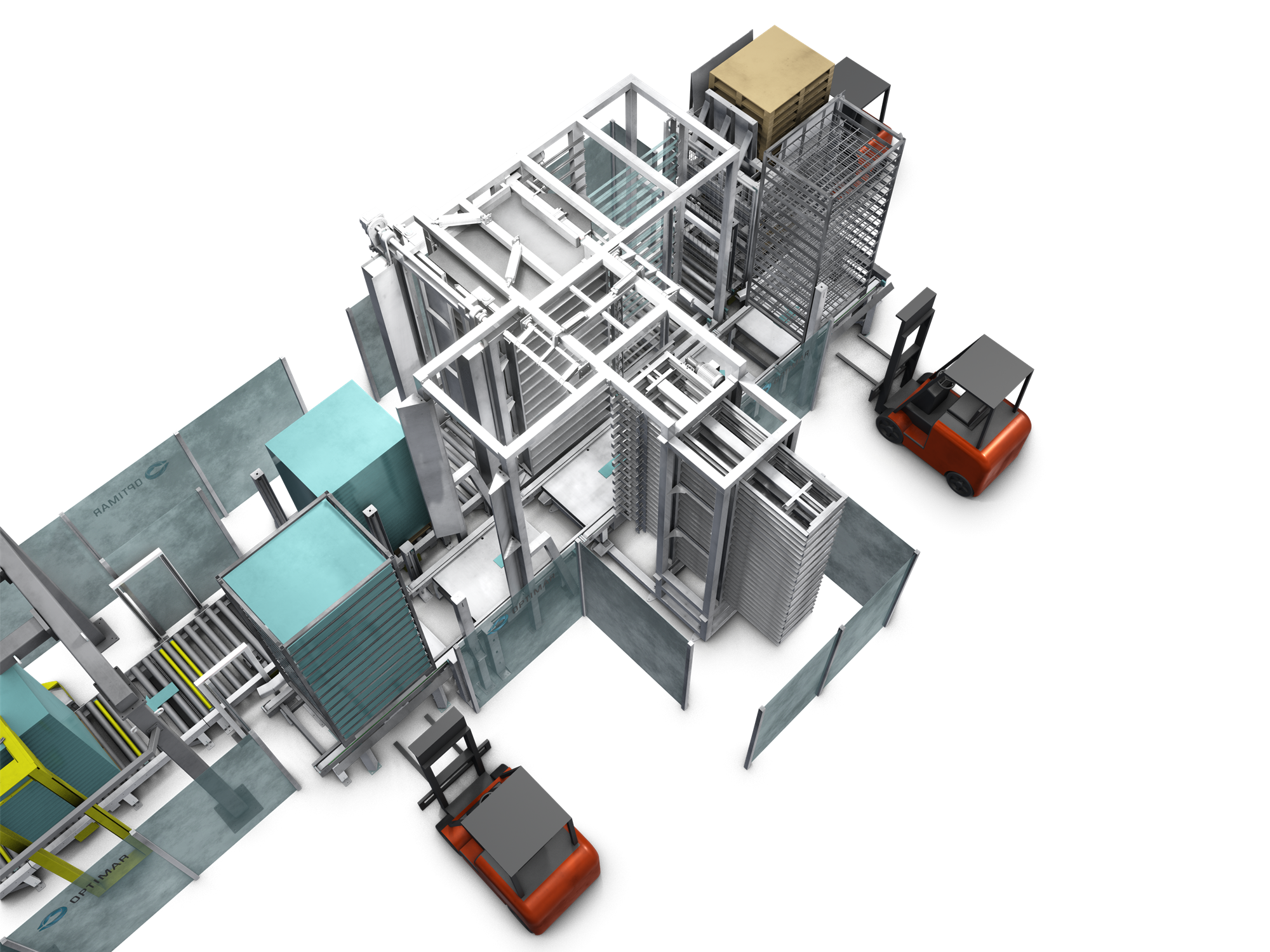

To begin, racks of frozen products are positioned into the machine on a chain conveyor, typically by the use of forklifts. From there racks are transported into the de-stacking zone.

The frozen products are pushed all at once onto retractable shelves and thereafter lowered onto an automatically vertically positioned pallet. And if there are deviations between numbers of layers between the rack and pallet stack , this is also calculated and accounted for.

Once the pallet is complete, it will be transported to an automatic plastic wrapper.

The finished pallets will be routed to the cold store by a conveyor system or by forklift handling

BENEFITS

- Very high-capacity de-stacker and palletizer for frozen cartons.

- Palletizer is delivered in stainless steel materials.

- Safety fences and safety barriers according to EU regulations.

- Touch screen operated control system.

SPECIFICATIONS

- Designed to palletize layers of 20kg cartons with footprint dimension of 400x600mm

- Number of shelves in racks: Up to 14.

- System capacity: Approx. 60-90 Ton/hour, depending on number of shelves in the freezing rack and number of layers on the pallet.

- The highest capacity is met when there is same number of shelves in racks as number of layers on pallets.

- Pallet size: 1000*1200 mm (US).

- Main power supply: 3x440V, 60Hz or 3x400V, 50Hz; 30 kW.

- Control voltage: 220V AC / 24V DC.

- Air supply: Appr. 200 Nl/min. (7Bar).