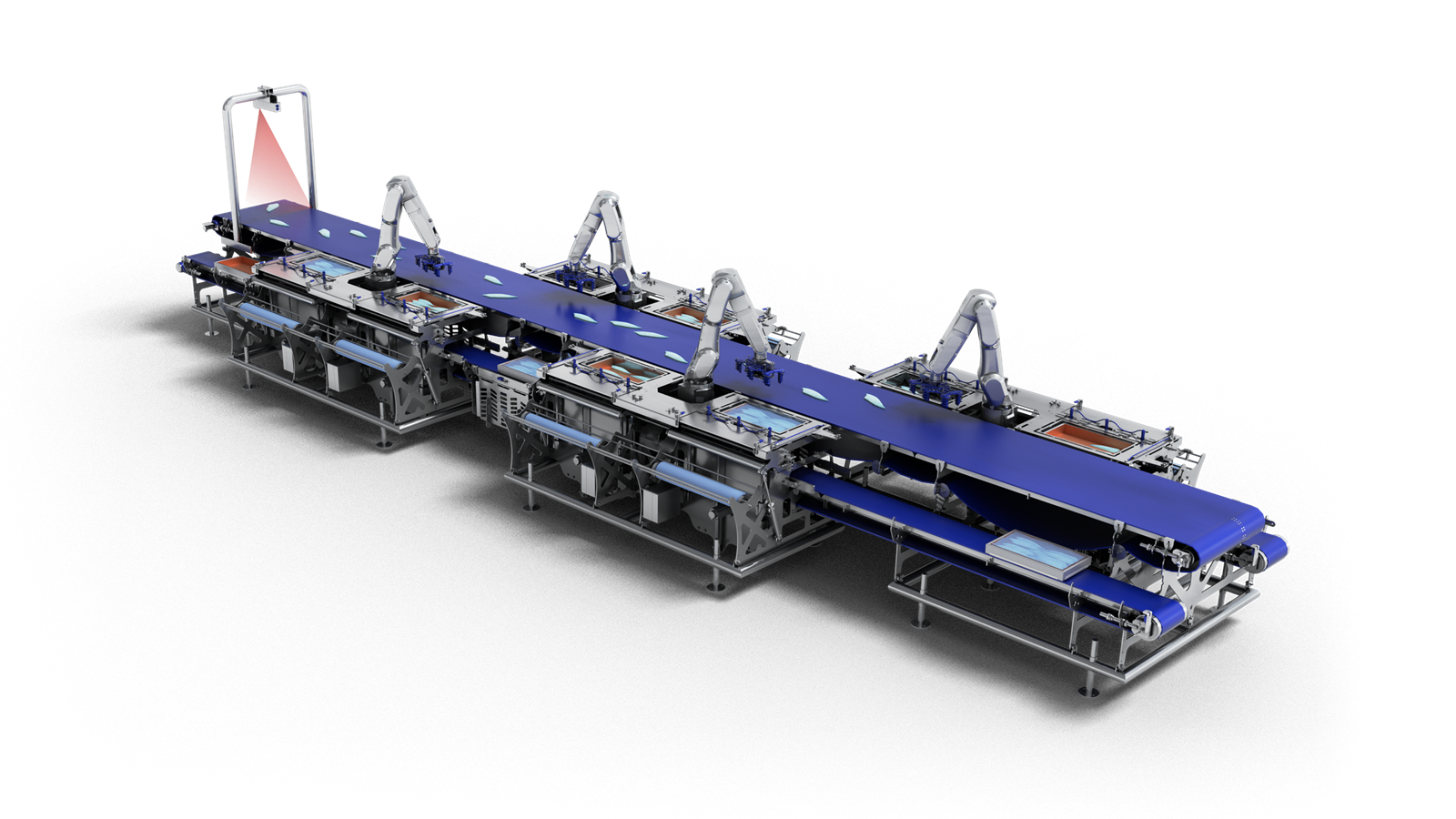

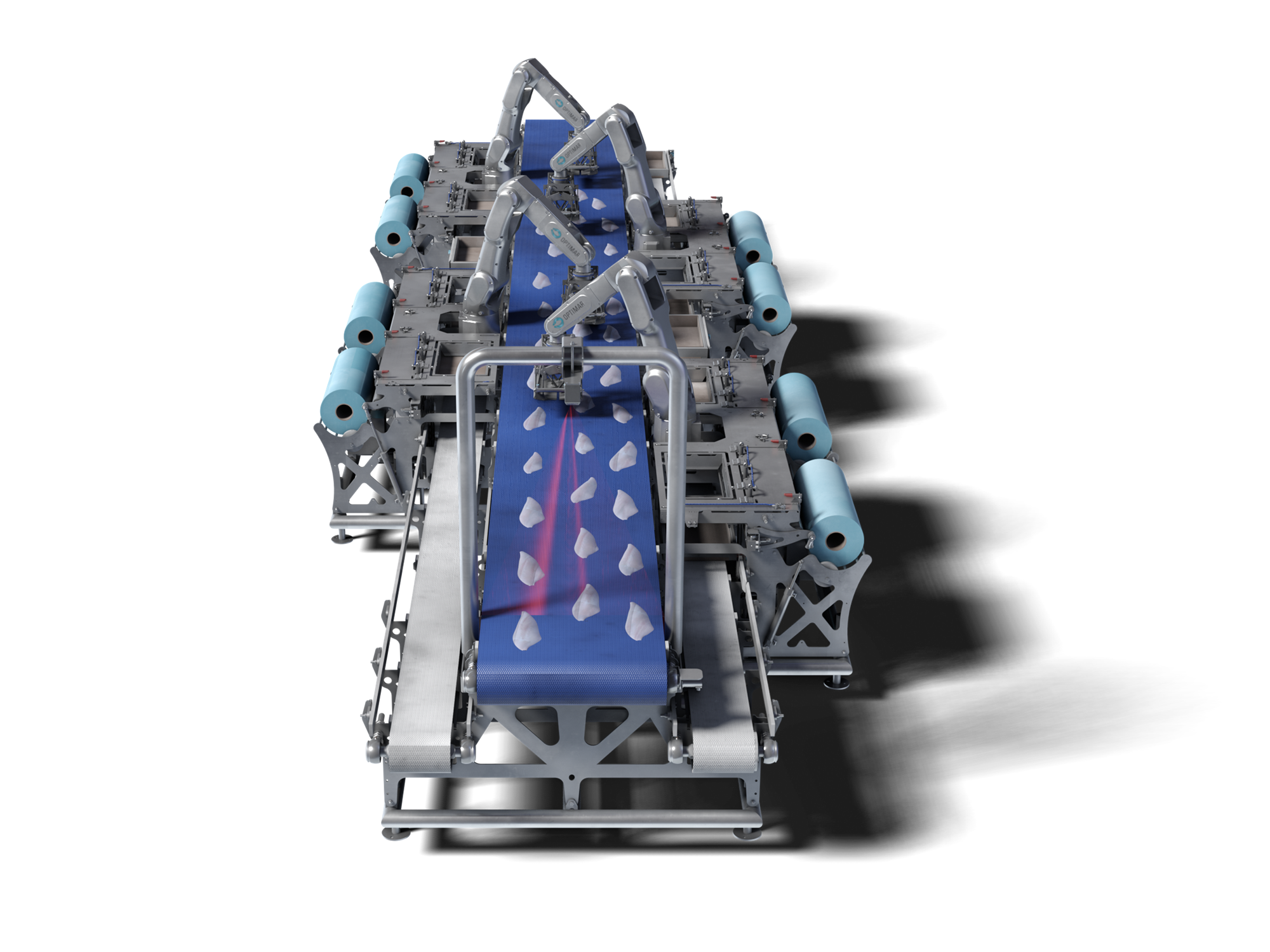

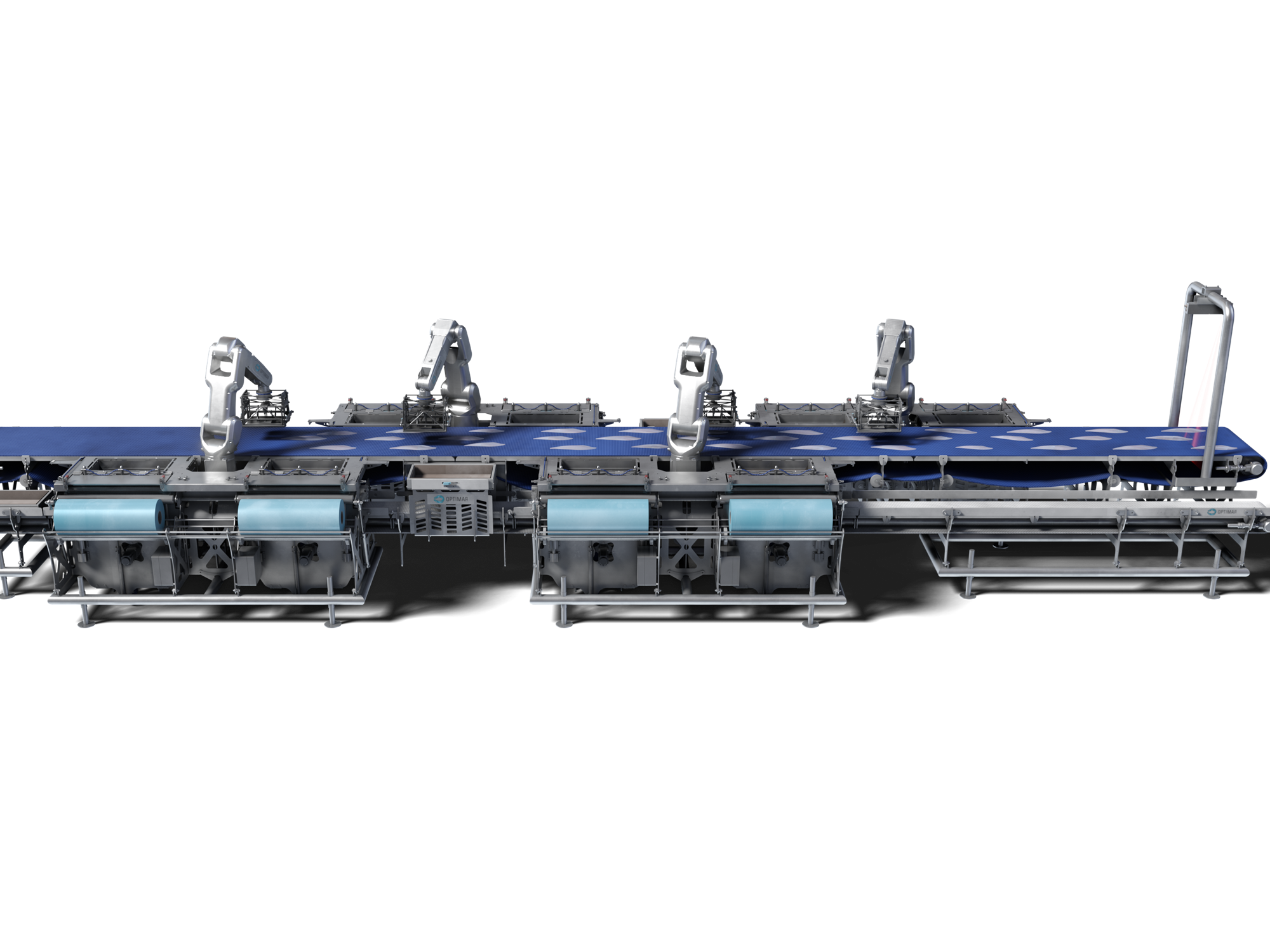

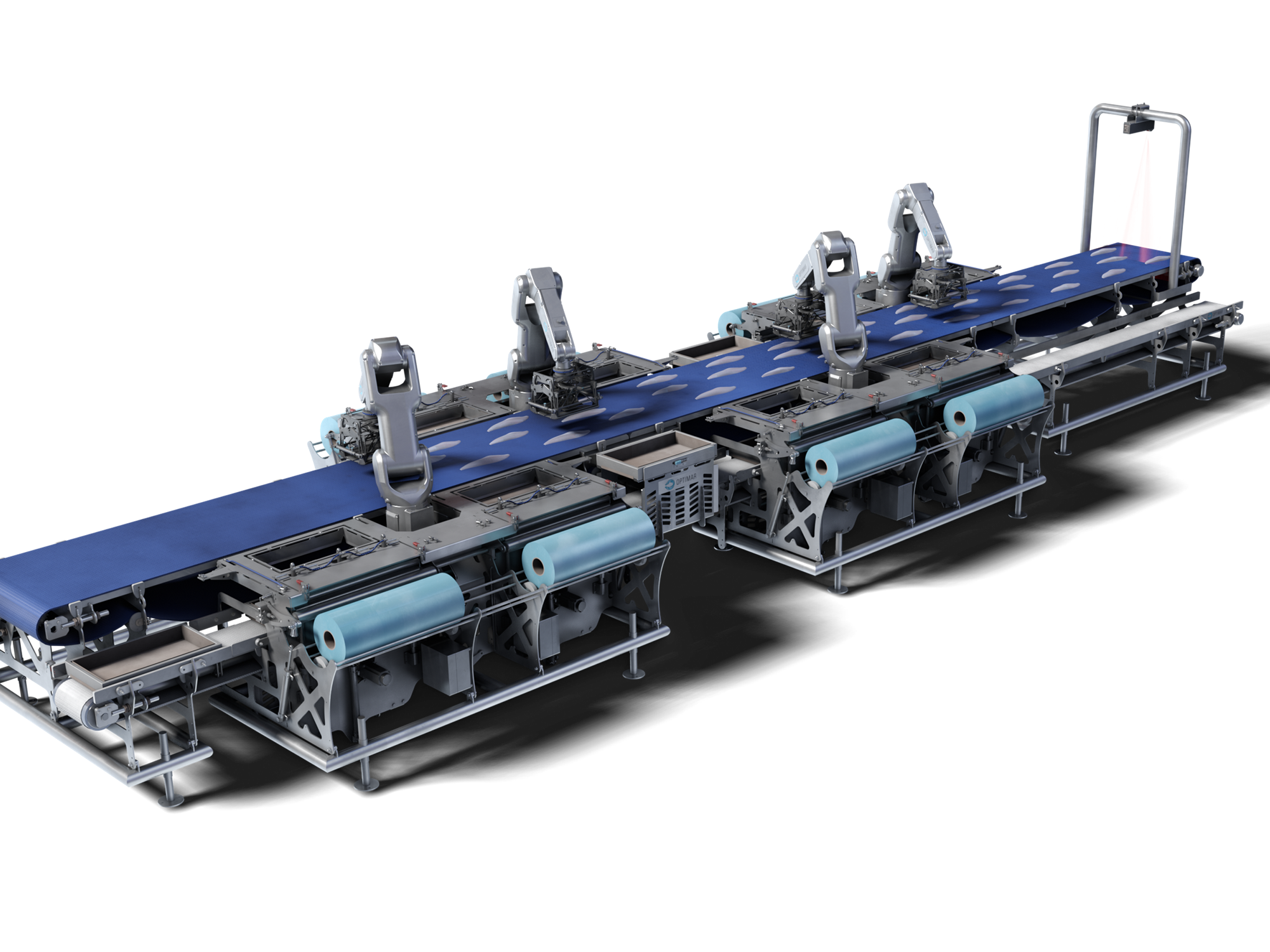

The automated packing table uses a pick and place solution done by a six axes robot and a self-developed interleave packing solution.

The automatic packing table is an automatic solution for weight estimation of the product, grading, packing with interleaving plastic layers, and box weight optimization.

This system has a modular design. Thus, the packing station and infeed conveyor can be assembled and configured as needed to achieve the desired capacity. The recommended minimum of modules would be two modules for efficient weight optimization for boxes and a minimum of 8 modules if the packing table also is going to be used as a grading solution.

CUSTOMER BENEFITS:

- Fewer people are required for packing operations, reduced labour costs.

- Increased accuracy of product weight.

- Less overweight on boxes.

- Compact all-in-one solution.

SPECIFICATIONS:

- LxWxH = 2,1 x 0,94m x 1,6 m.

- Estimated capacity: 38 units per minute per module (Product weight: 2 kg).

- Modular and scalable solution.

- IP 67.

- Weight per module 350 kg.

- Supported fish types: Cod fillets, Rose fish.

- Future supported fish types: Mackerel, round and fillets - Salmon; round and fillet.