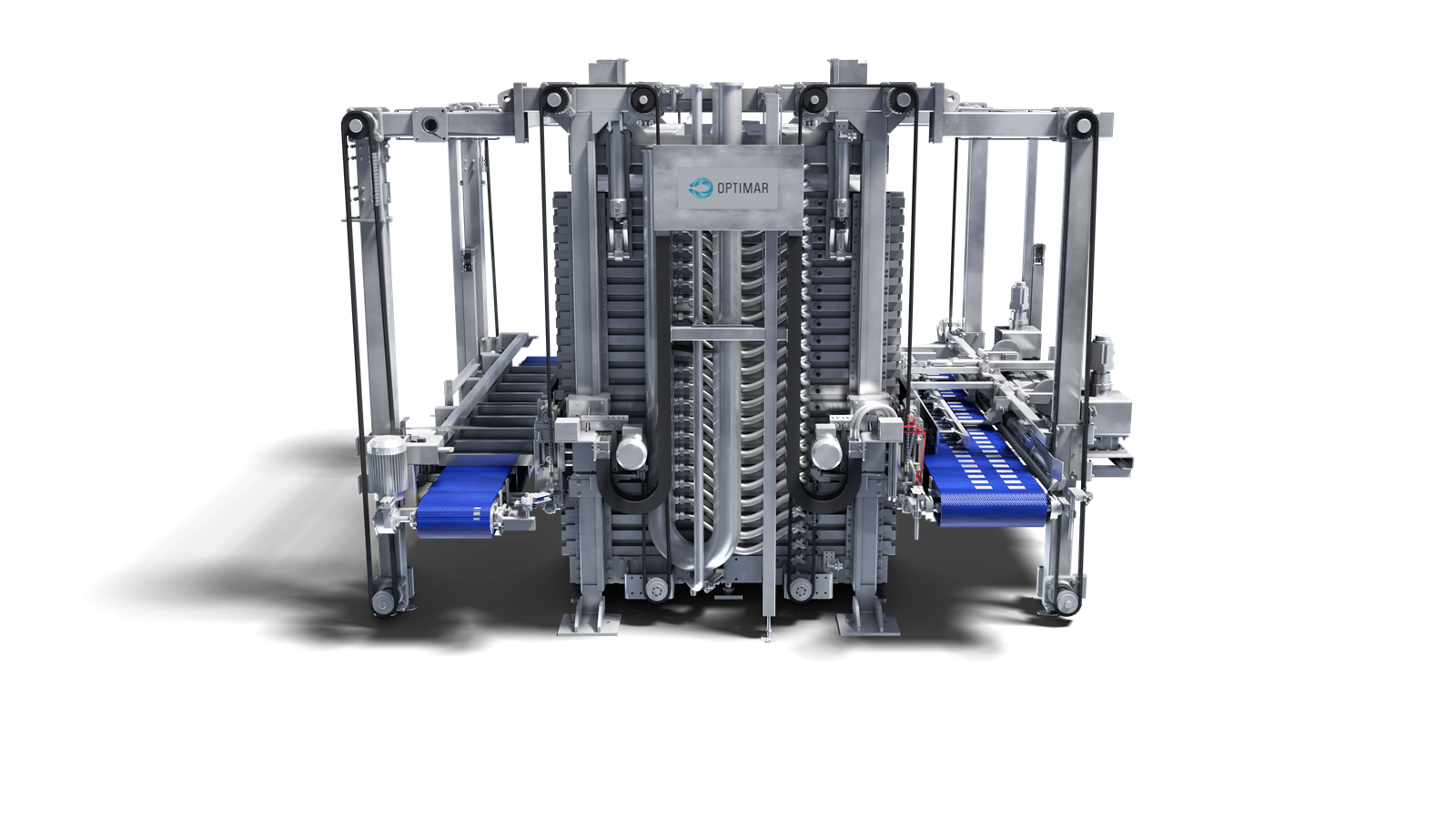

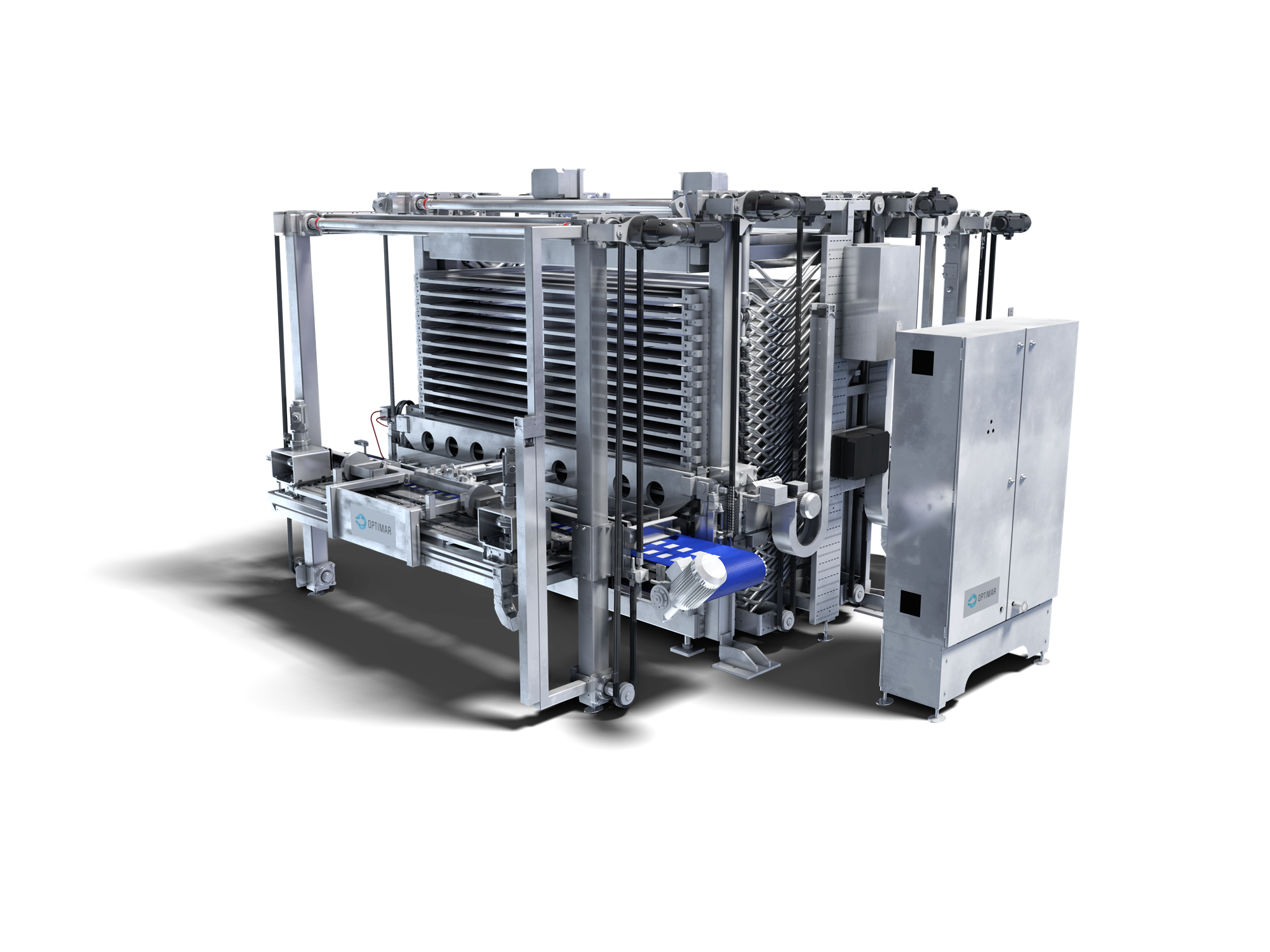

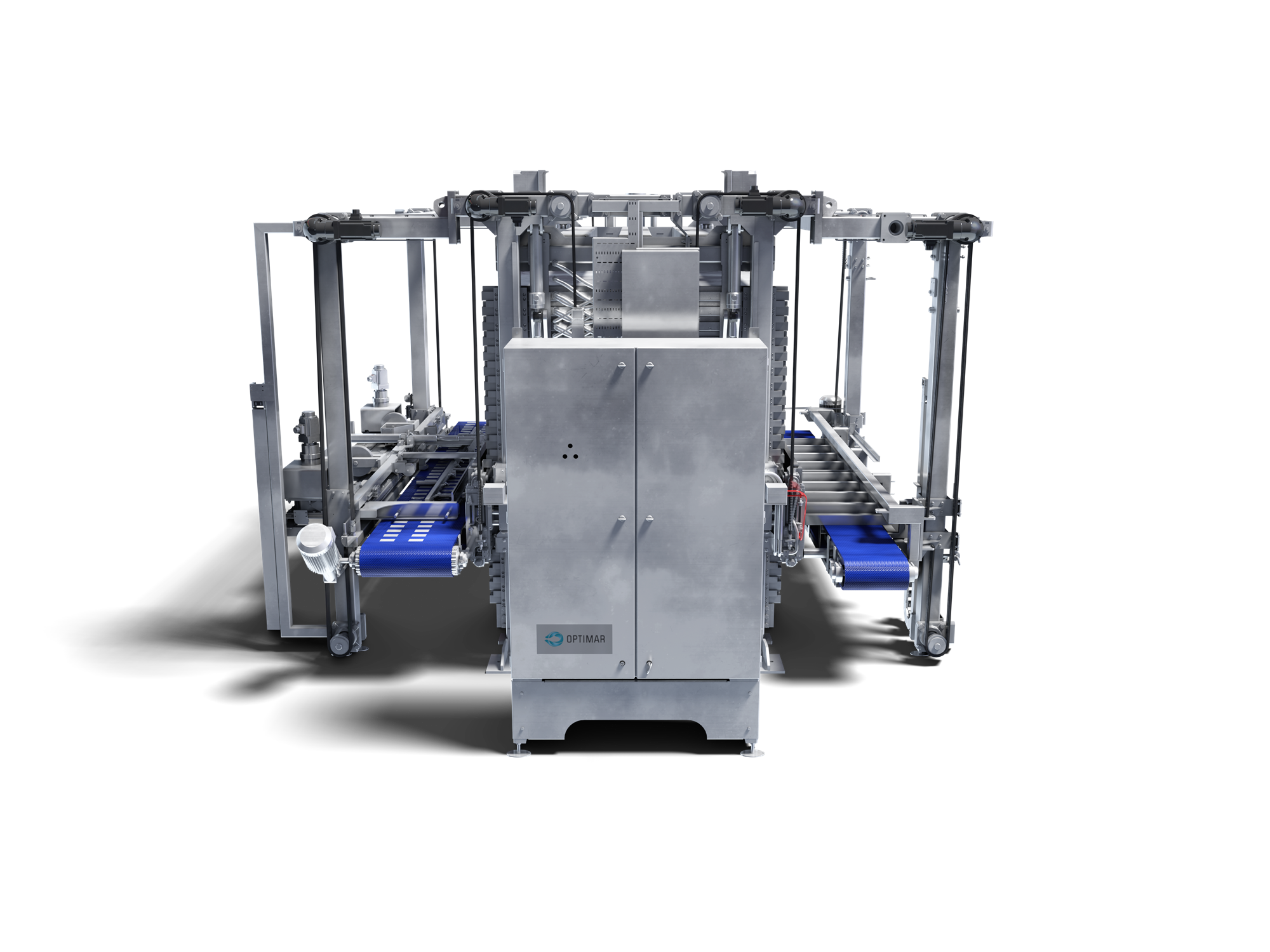

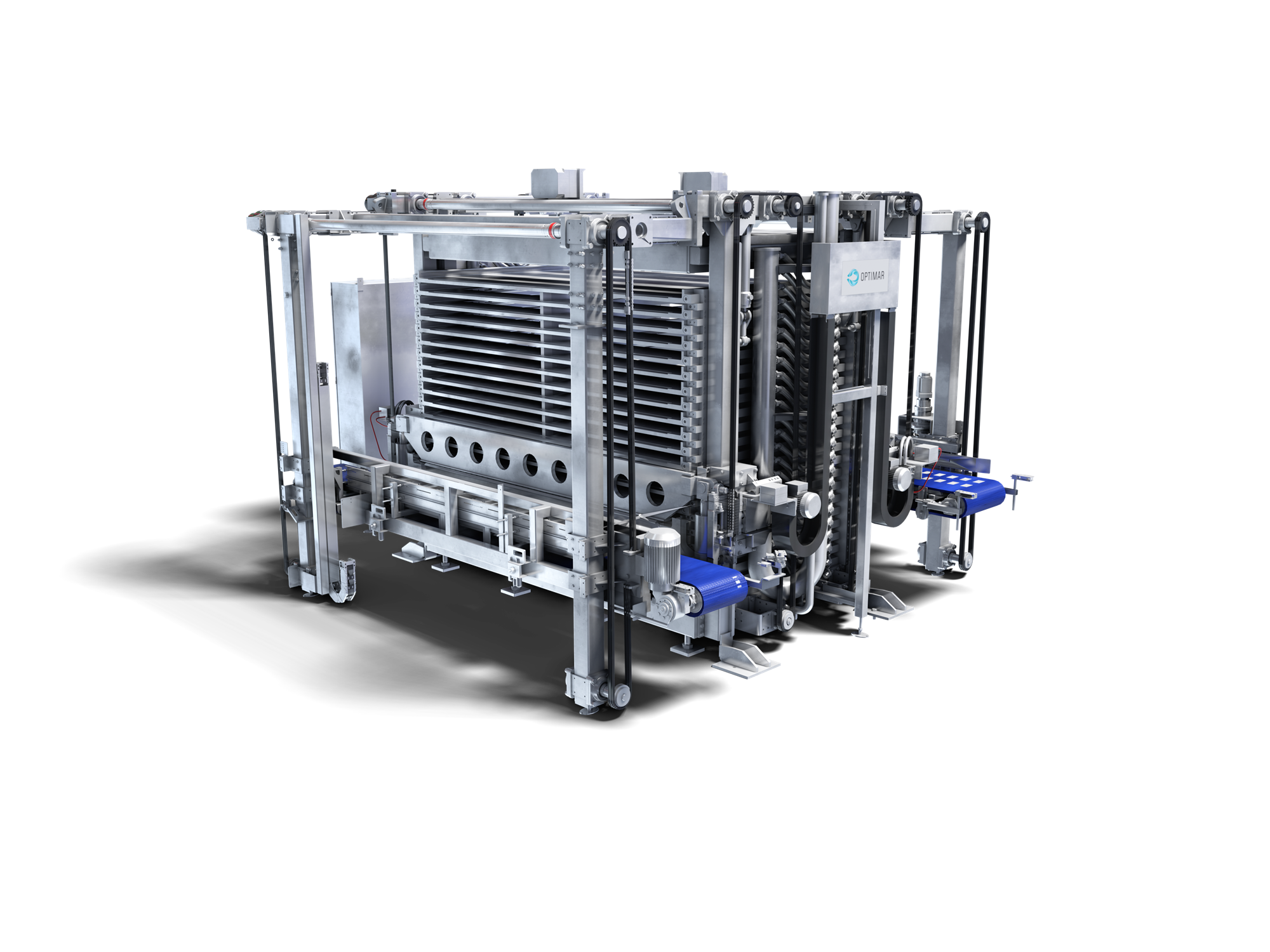

HOW DOES IT WORK:

The freezer has a plate stack that is placed under the pressure of a top frame held down by pressure cylinders that ensures maximum product contact and quick freezing. To open the plate stack when feeding in products, an opening tool is positioned on each side of the stack with the station that is to be filled, and there after opens the plate stack by the use of high power cylinders. If requested the plate stack pressure tool can simultaneously provide full pressure also during opening of the plate stack. When the plate stack has one station opened, a loading unit will quicky feed products into the opening. When the freezer is fully loaded with products, a row of finished products will go out to an outfeed unit each time a new row of products is pushed in. Between each cycle the return pusher ensure that products are appropriately positioned on the freezing plates. When the freezer is to be emptied, the infeed process stops while the outfeed process continues all the way until the freezer is empty. The emptying goes fully automatic regardless of how many frame inserts contained.

The freezer can be fitted with an automatic washing system that CIP-washes and wipes of the freezing plates.

BENEFITS:

- Individual infeed and outfeed which makes it easier to integrate with rest of factory without bad compromises.

- Individual flexible heights on the infeed and outfeed.

- Via the constant pressure solution you will have a better freezing efficiency during loading and emptying.

- The fast moving elevators is perfect for high capacity demanding factories.

SPECIFICATIONS:

- 18 stations a 60mm height or according to costumer request.

- Plate usable size 2450x1685 or according to costumer request.

- Total Height 2600mm as standard.

- Total footprint 4300x4400mm as standard.

- Weight 13000kg as standard.

- Special designed aluminium freezing plates.

- With CO2 refrigerant freezing time can be as low as 75 minutes for a 60mm block.

- Total capacity approx 2500kg/hour.

- Loading and unloading time approx 1 minute per station.

- Hydraulic oil pressure 160 Bar, 60L/minute.

- Power 480V, 3 phase, 60hz, 4-wire. 15kW.

- Refrigerant CO2/ammonia.