BENEFITS:

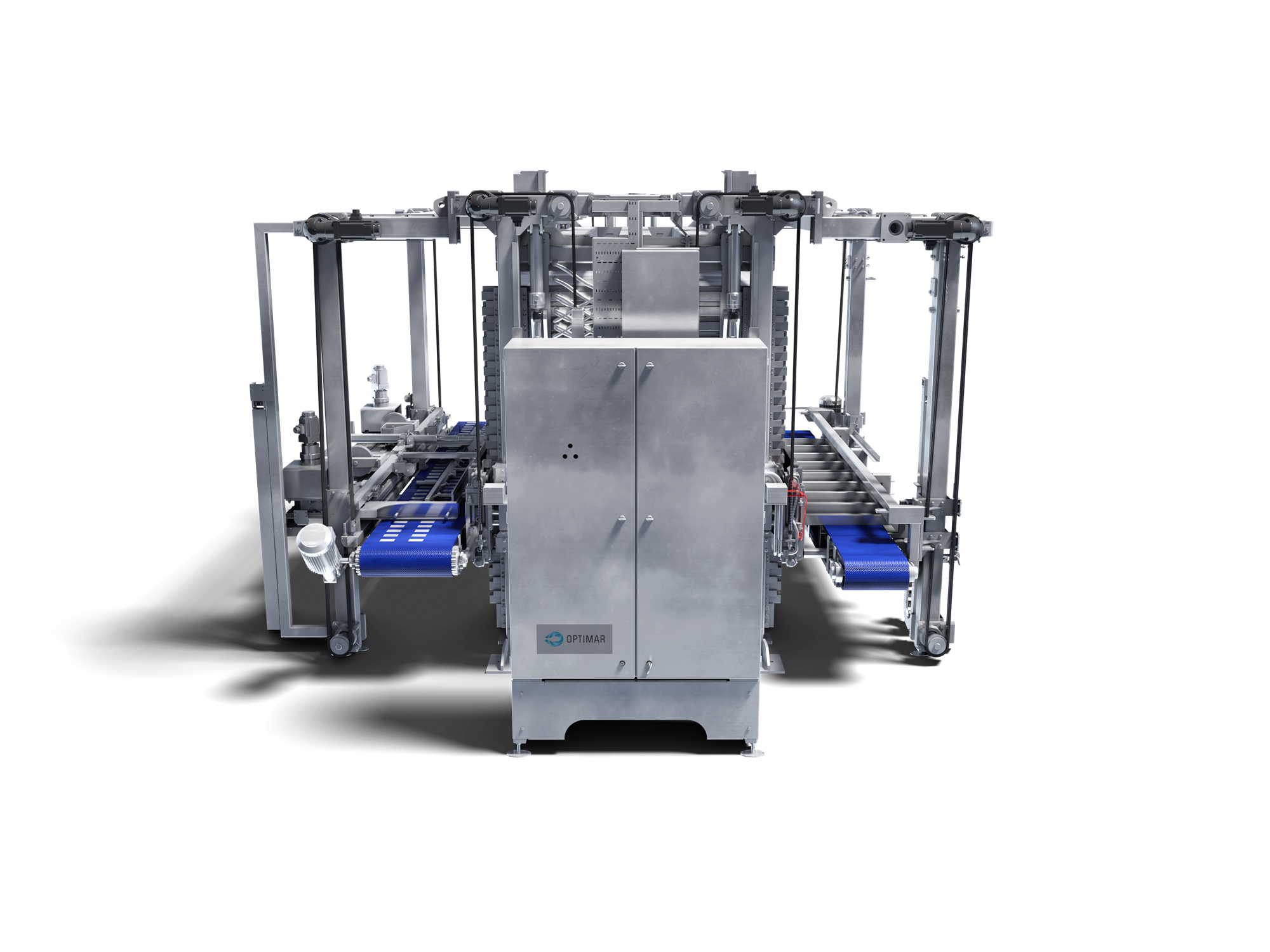

- The freezer can be fitted with a semi automatic washing system that CIP-washes and wipes of the freezing plates.

- The freezer is designed in a food safe manner so that product zones are protected from pollution and is easily cleanable.

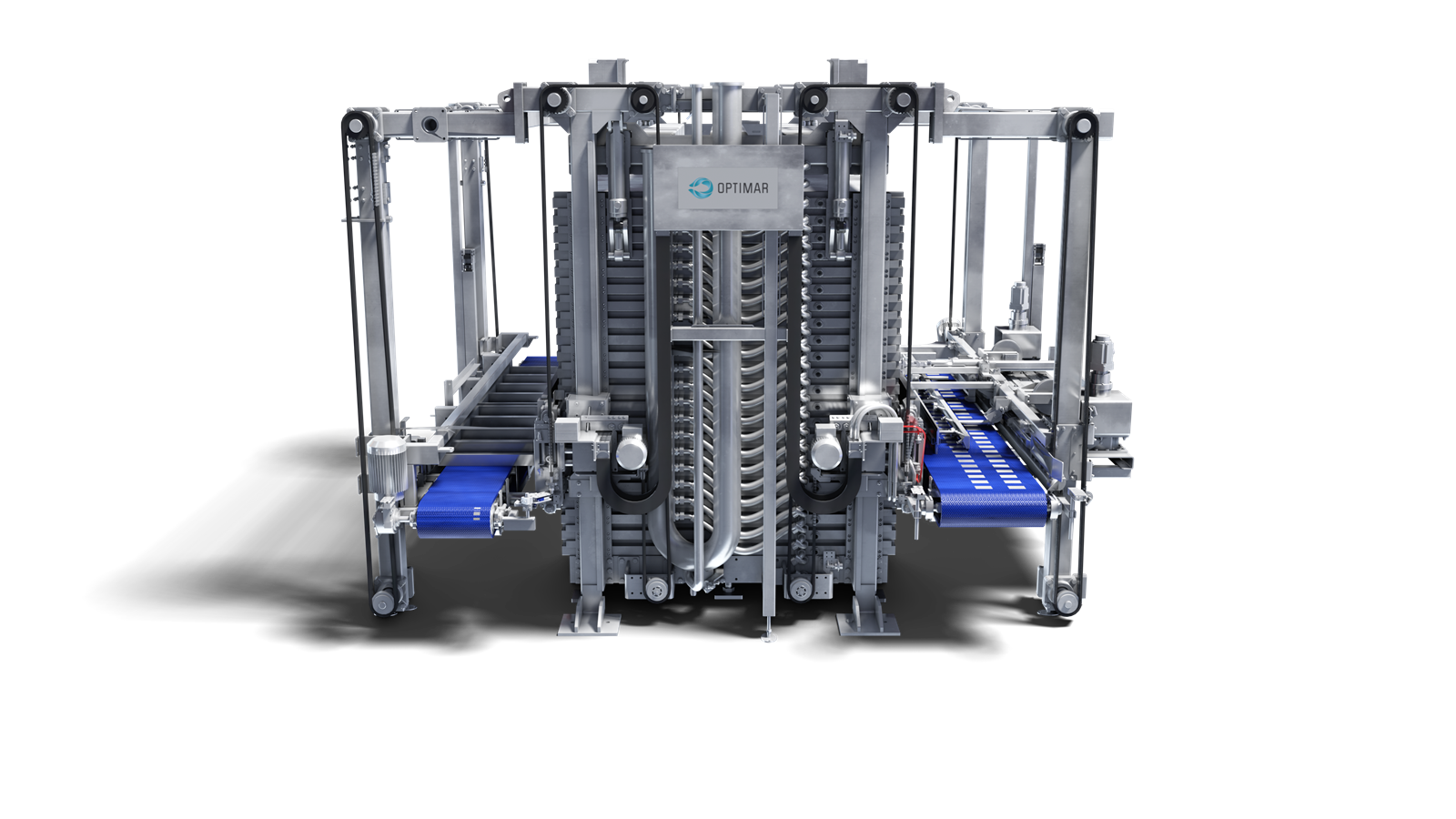

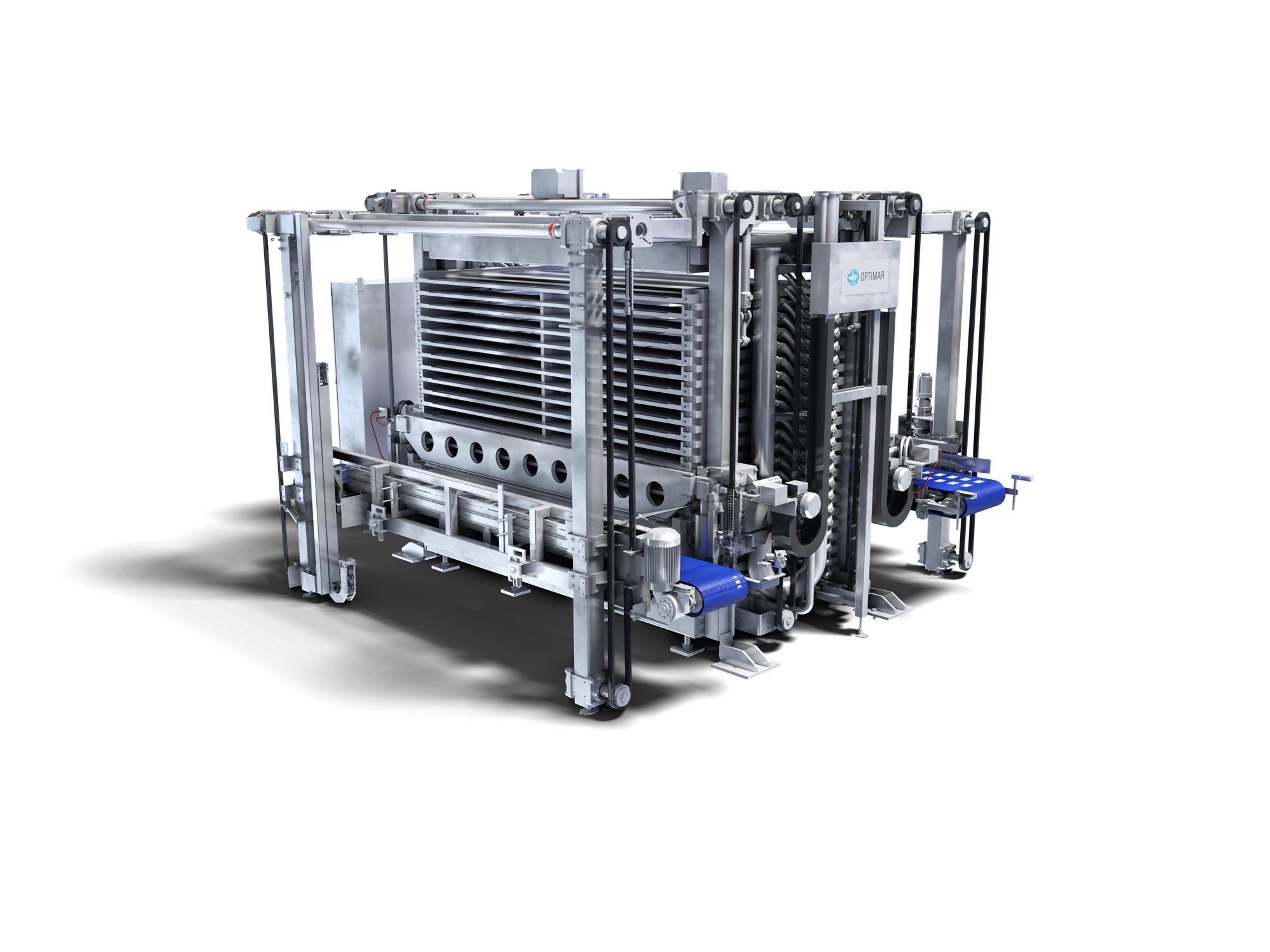

- Equipped with a compact chain pusher (Optimar patent) that in addition to provide the infeed and outfeed of products also ensures the possibility to automatically empty the freezer for all frames before washing.

- The adjustable plate pressure functionality improves the product contact surface and reduce the freezing time. (Standard pressure 0,7 bar/10psi on product)

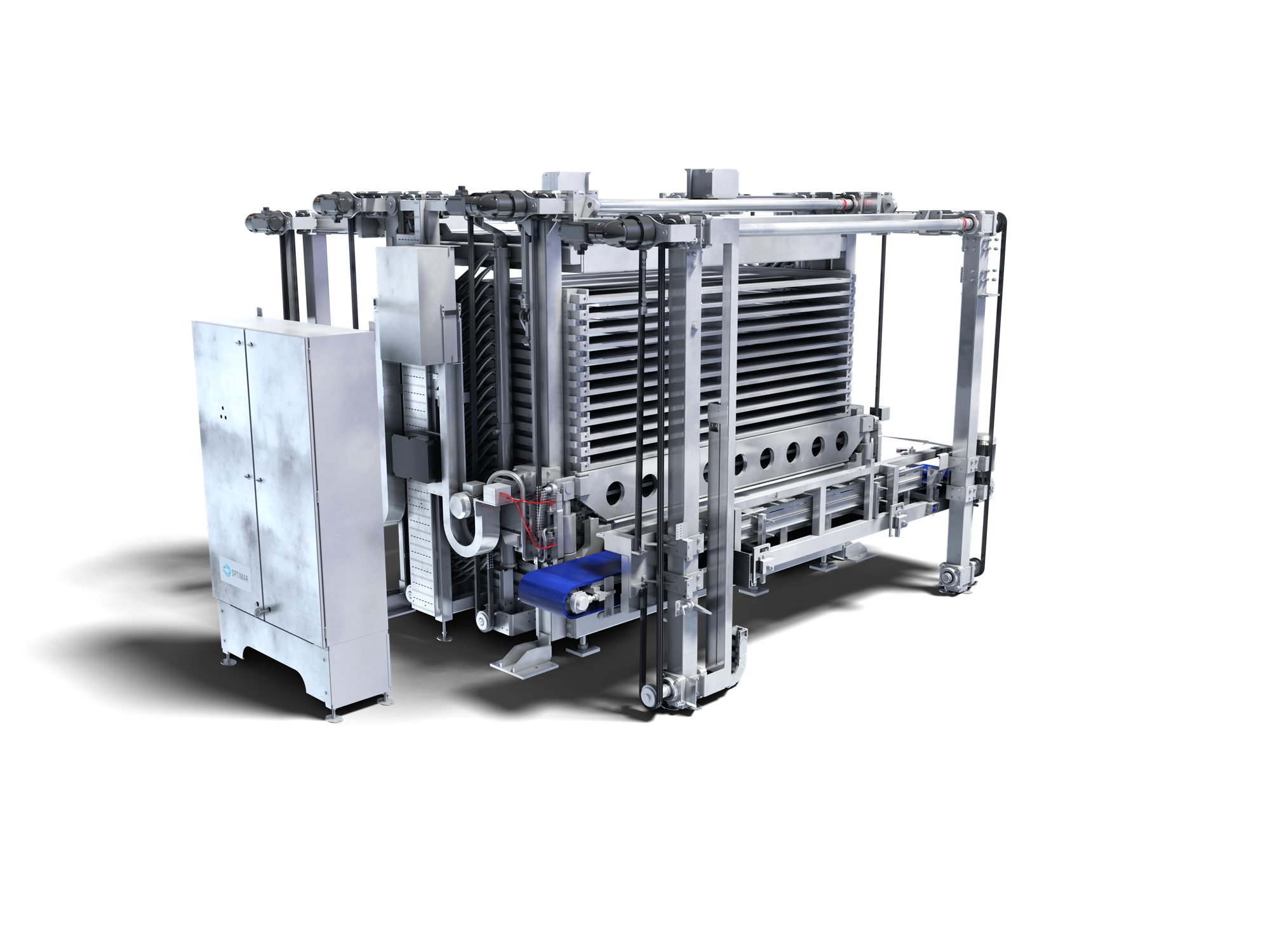

- The freezer can optionally be equipped with “constant pressure”. This gives equal pressure also during loading and unloading.

- Loading and unloading elevators runs independently from each other and are able to automatically adapt for varying freezing expansion within the plate stack.

- The freezer can also be configured for use as a batch freezer (multipurpose freezer).

SPECIFICATIONS:

- Configurable number of stations (21 is standard).

- Can handle various frame sizes, and more than one frame size (Standard plate = 2450 x 1800mm but configurable).

- Can be fitted both for CO2 and ammonia (CO2 is the recommended selection).

- A full plate stack pressure mechanism ensures maximum contact surface and minimum freezing time.

- 60-100 tons per day depending on product, size, temperature requirements and type of freezing plant. Freezing time to be calculated and/or tested to decide final capacity.

- Loading and unloading is approx. 20 seconds per row (3 rows per station = 1 minute).

- Power 480V, 3 phase, 60hz. 15kW.

- Hydraulics 160 Bar, 60L/minute.

- Minimum operating temperature is -34⁰c.

Technical Specifications