HOW DOES IT WORK:

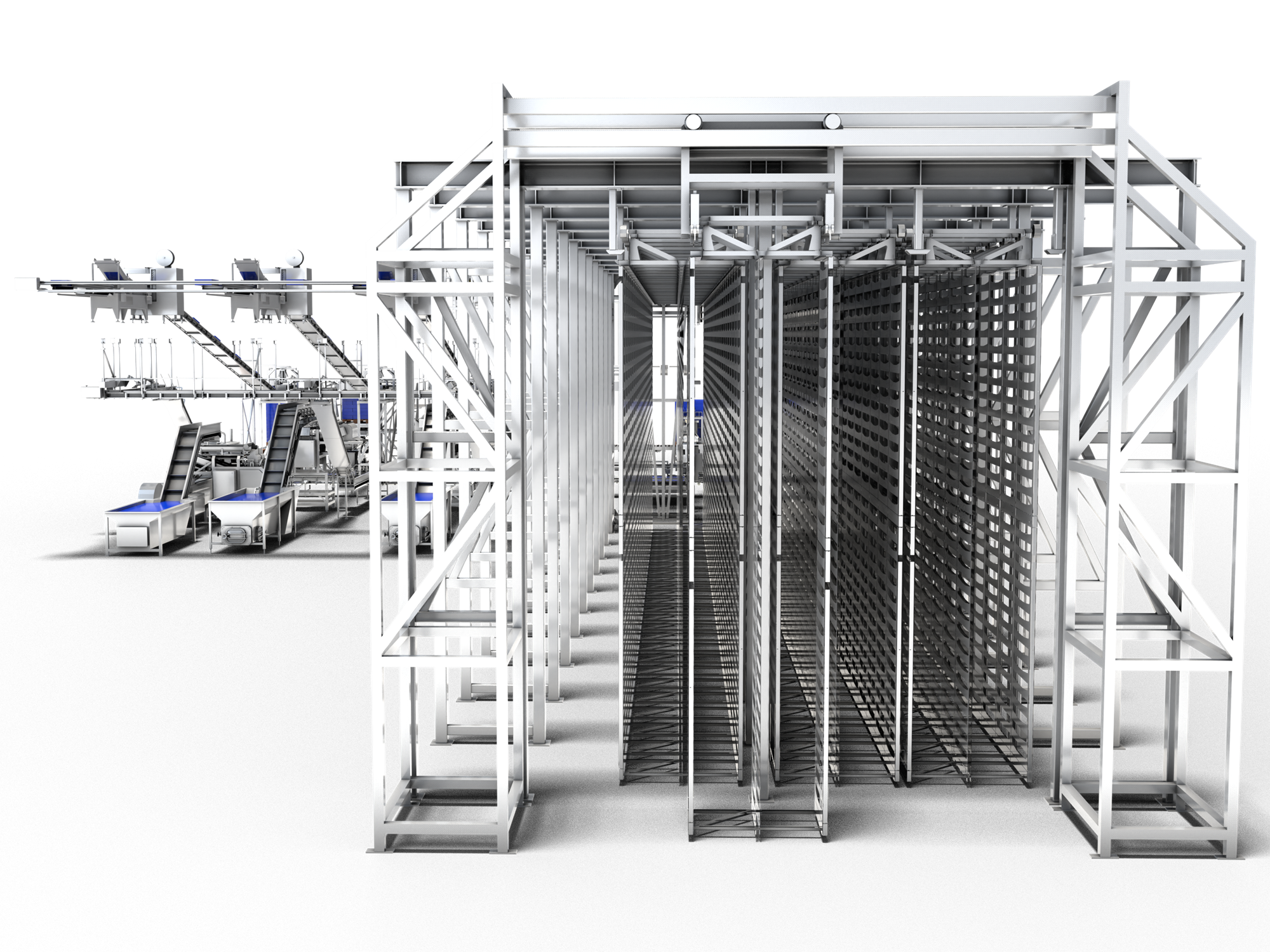

Energy savings are significant because no large doors are repeatedly opening and closing. Freezing racks remain inside the refrigerated area throughout the process so no energy is wasted warming up or cooling down the steel frames.

Loading and unloading are continuous – one stations and one rack at a time – so, unlike traditional static blast freezers, there are no energy peaks or valleys.

Continuous freezing also eliminates the risk, common to static tunnel systems, of compromising product quality due to warming, dripping or leaking when products are waiting for a tunnel to be filled.

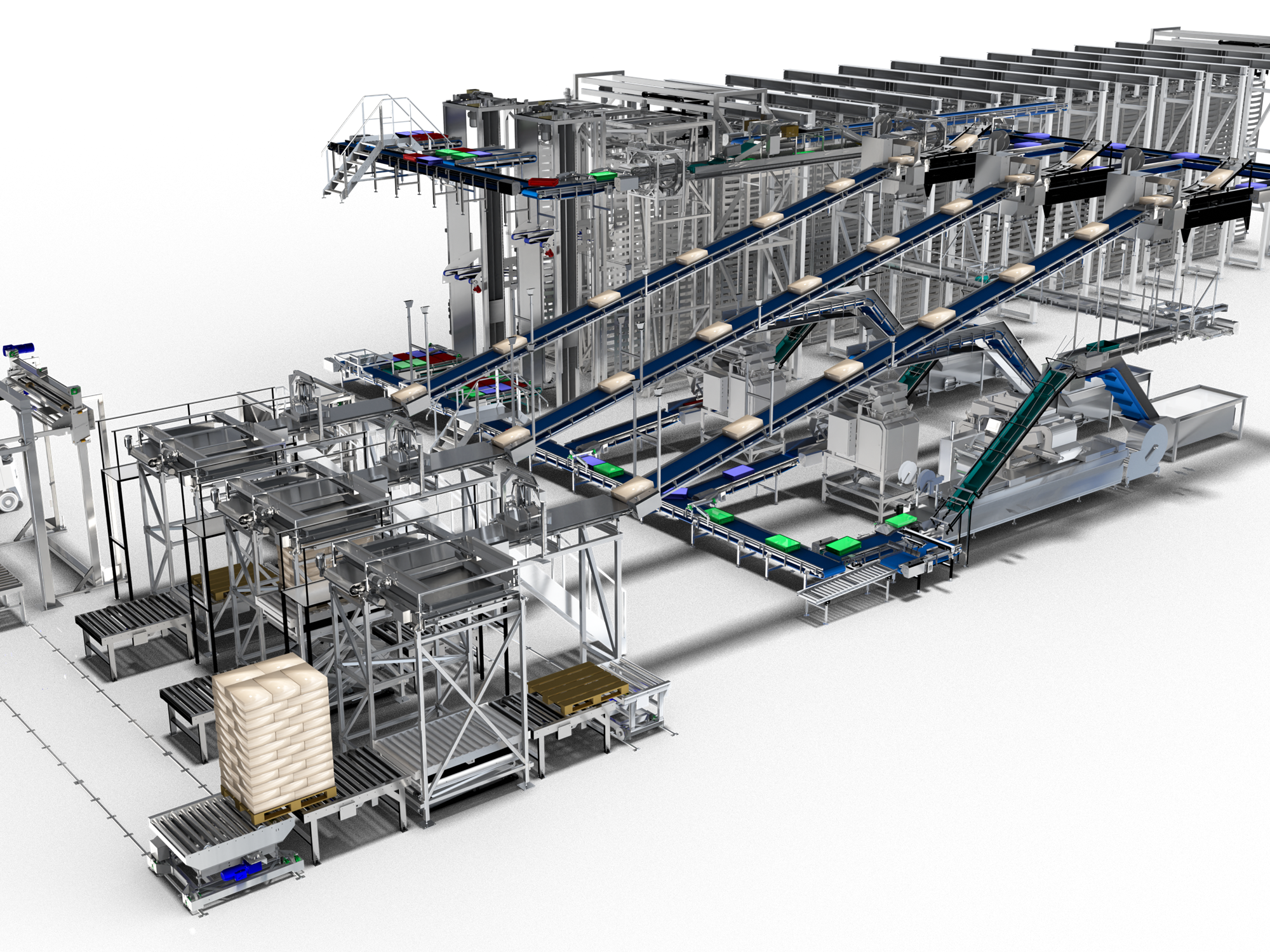

BENEFITS:

- Reduce the area required for freezing by as much as 50%

- Eliminate manual labor and forklifts

- Reduce energy consumption and costs

- Reduce packaging costs

- Improve health and safety in the work environment

- Contribute to improving the global environment

- Ensure product safety and hygiene

- Guarantee product quality.