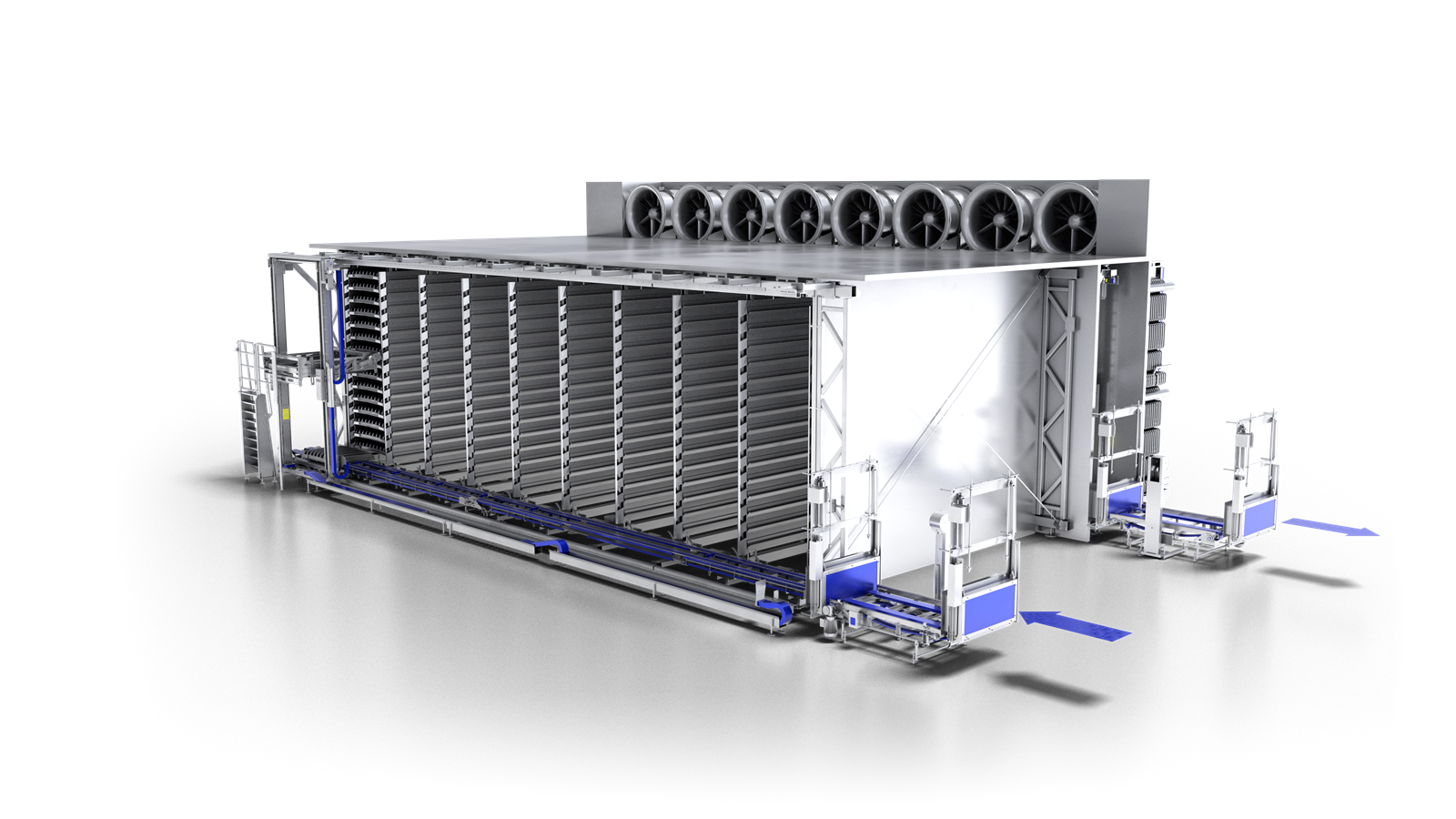

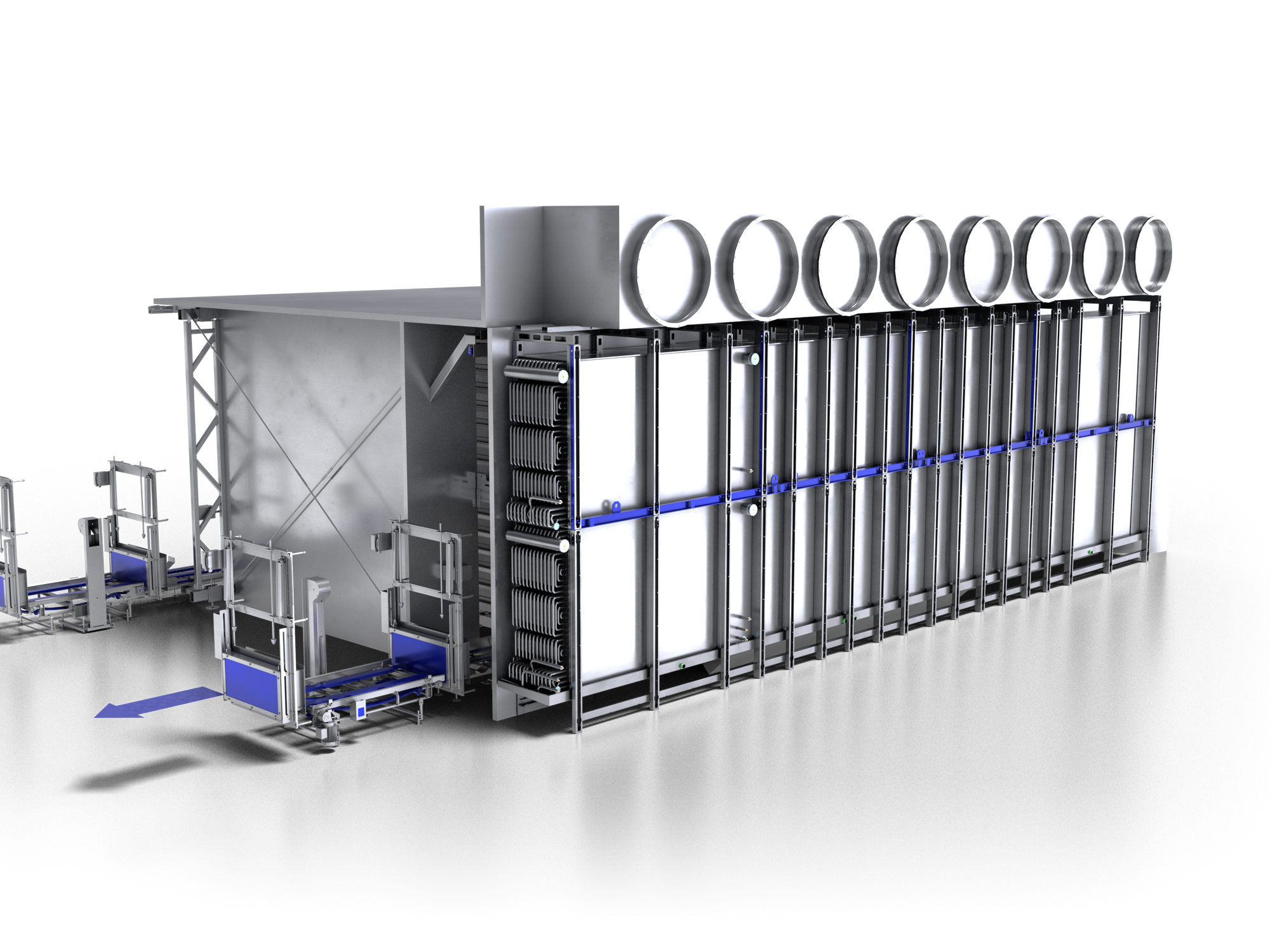

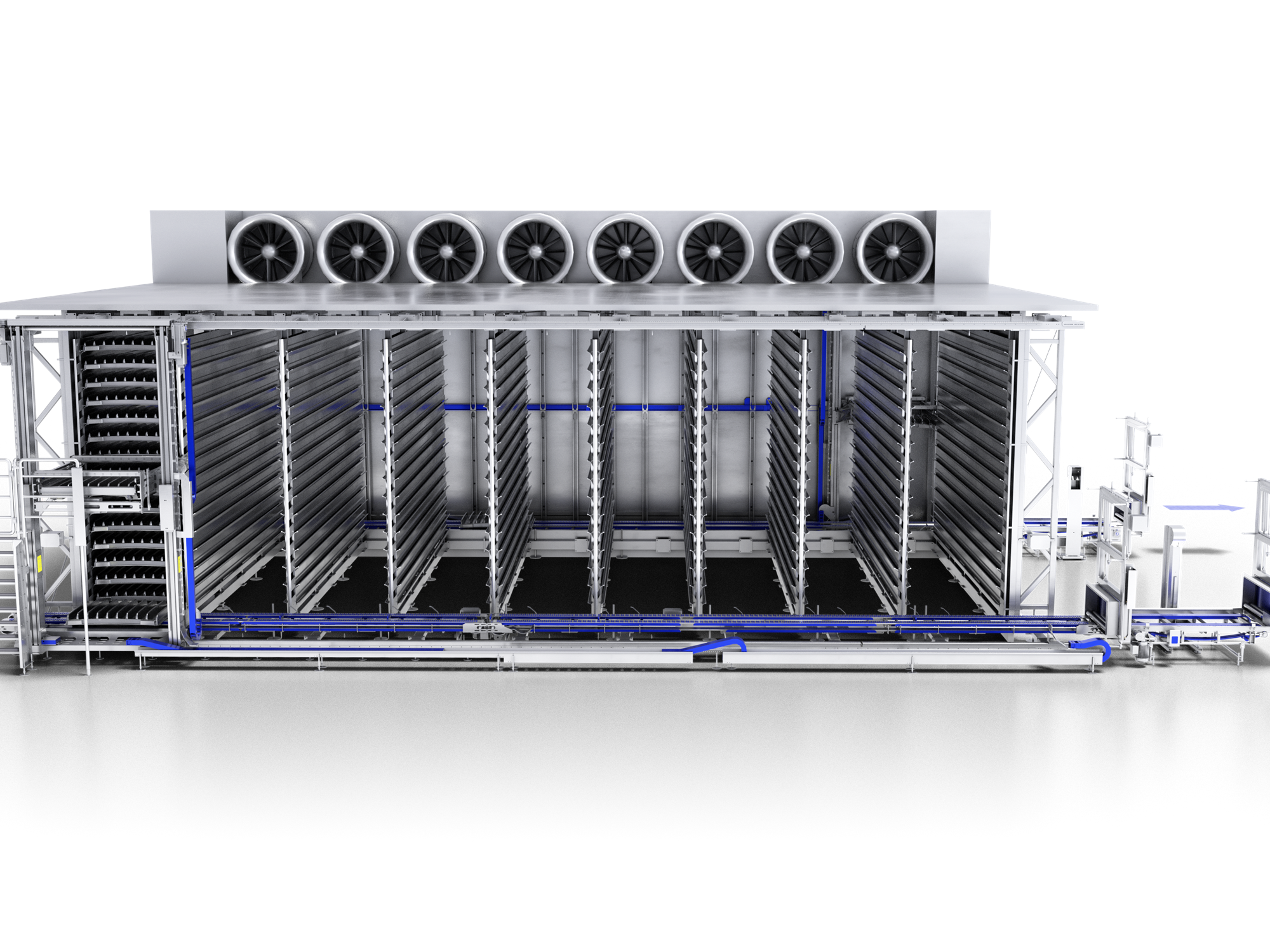

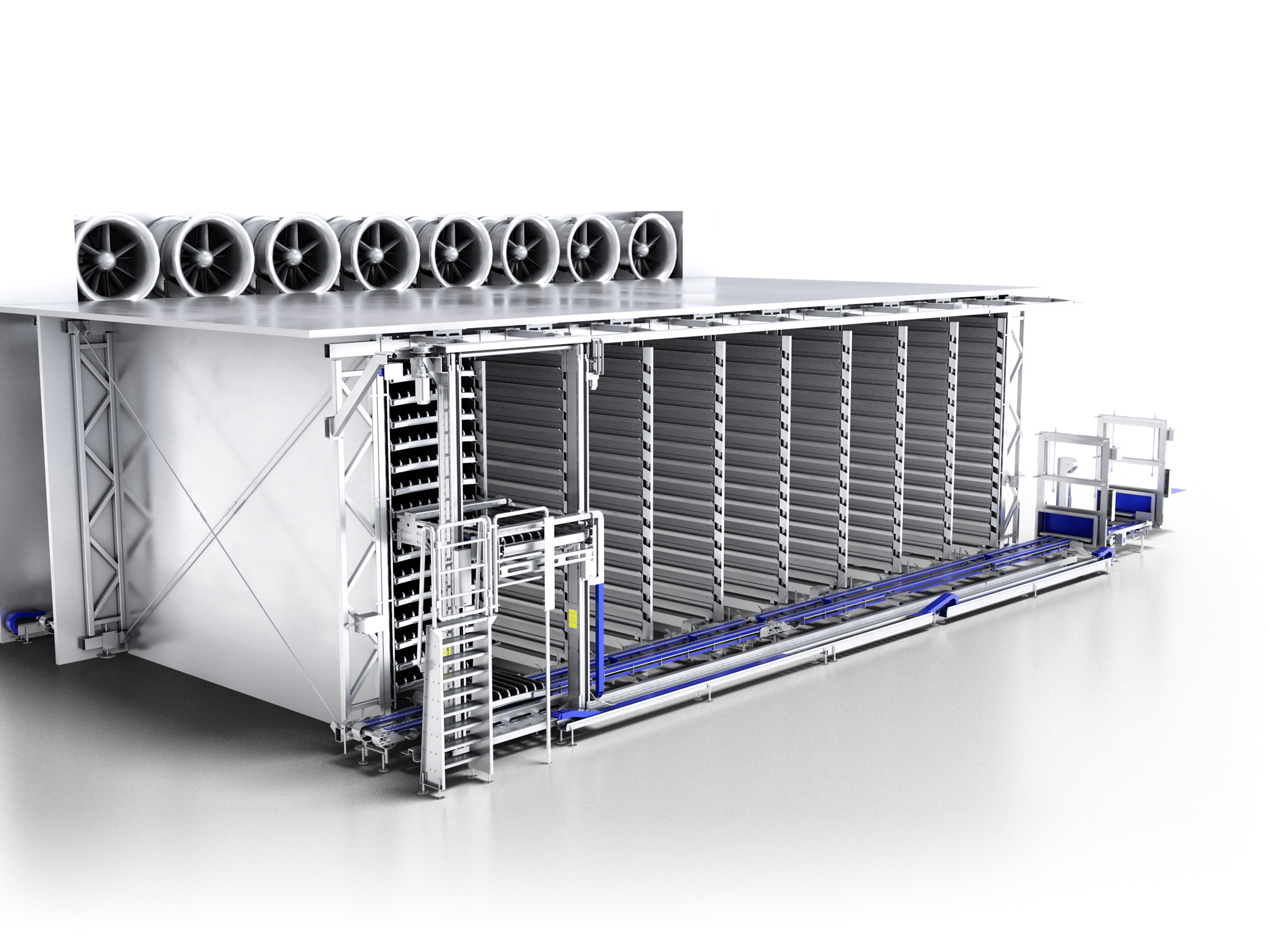

Fish get stored in tray and get transported to the freezer. Two lock hatches prevent the “warm” air form the factory to come directly into freezer. Automatic elevators will place the tray in pre-defined shelving, and the system start to log freezing time. After freezing time has been achieved the elevator pick the tray and the transport out of the freezer starts. Two lock hatches prevent the “warm” air form the factory to come directly into freezer also for the output line.

CUSTOMER BENEFITS:

- Less people needed for operating the system.

- Proper freezing time in freezer.

- No needs of people inside Freezer.

- Truck not needed for transporting product

into freezer.

SPECIFICATIONS:

- LxWxH = … 11,6 x 9,9m x 5,7 m.

- Hight between shelf: 240 mm.

- Estimated capacity: 50 t, 8 hours production time (fish size 4 kg).

- Arranged for saddle, wave and flat tray.

- Can be extended in length direction unlimited.

- Elevator speed: 3 trays per minute.

- Freezer temperature -35°.

- Product temperature before freezer 4°.

- Supported fish types:

- Salmon (round and filet).

- Trout (round and filet.)

- Can be used for all type of products.