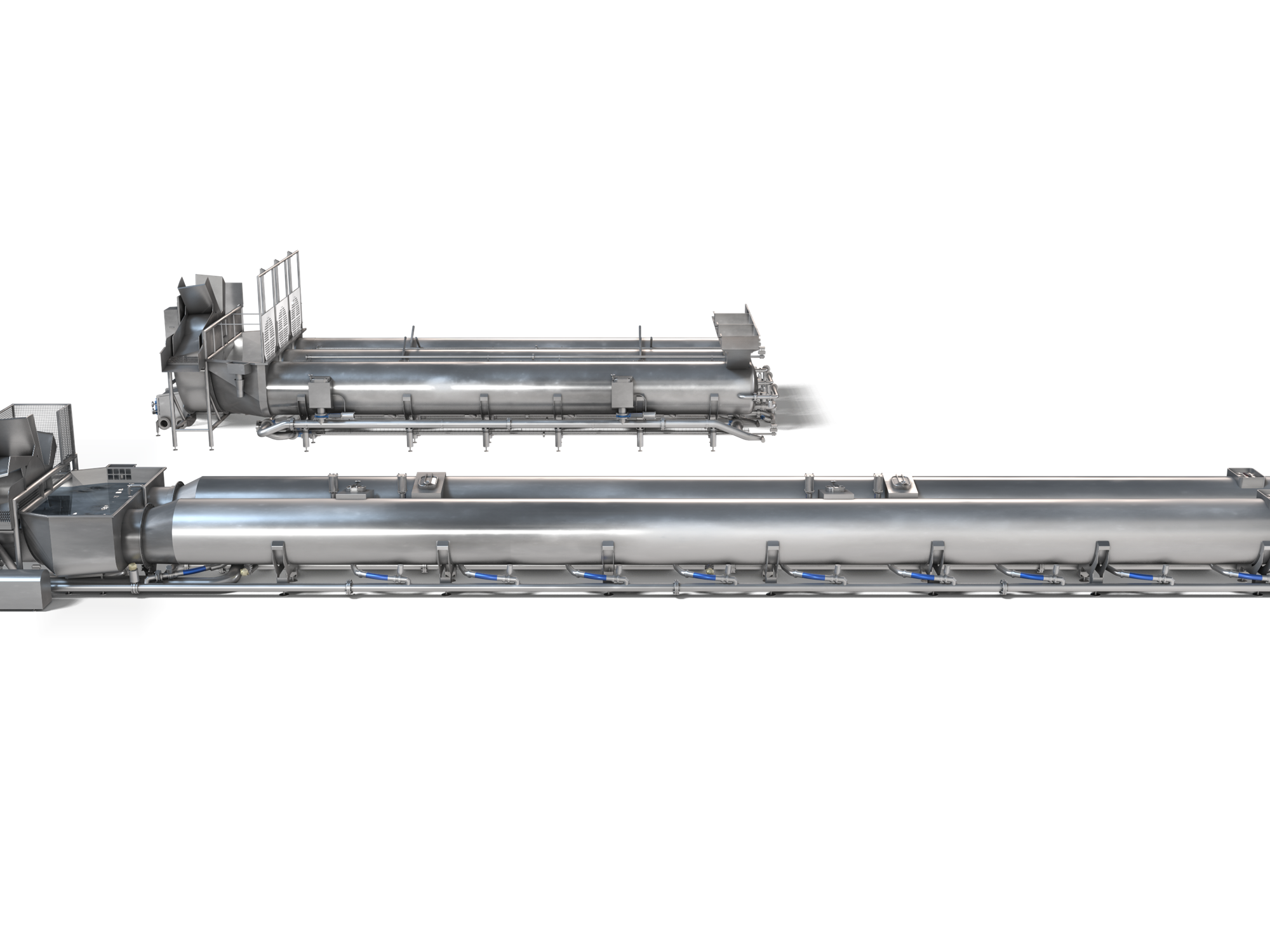

HOW DOES IT WORK?

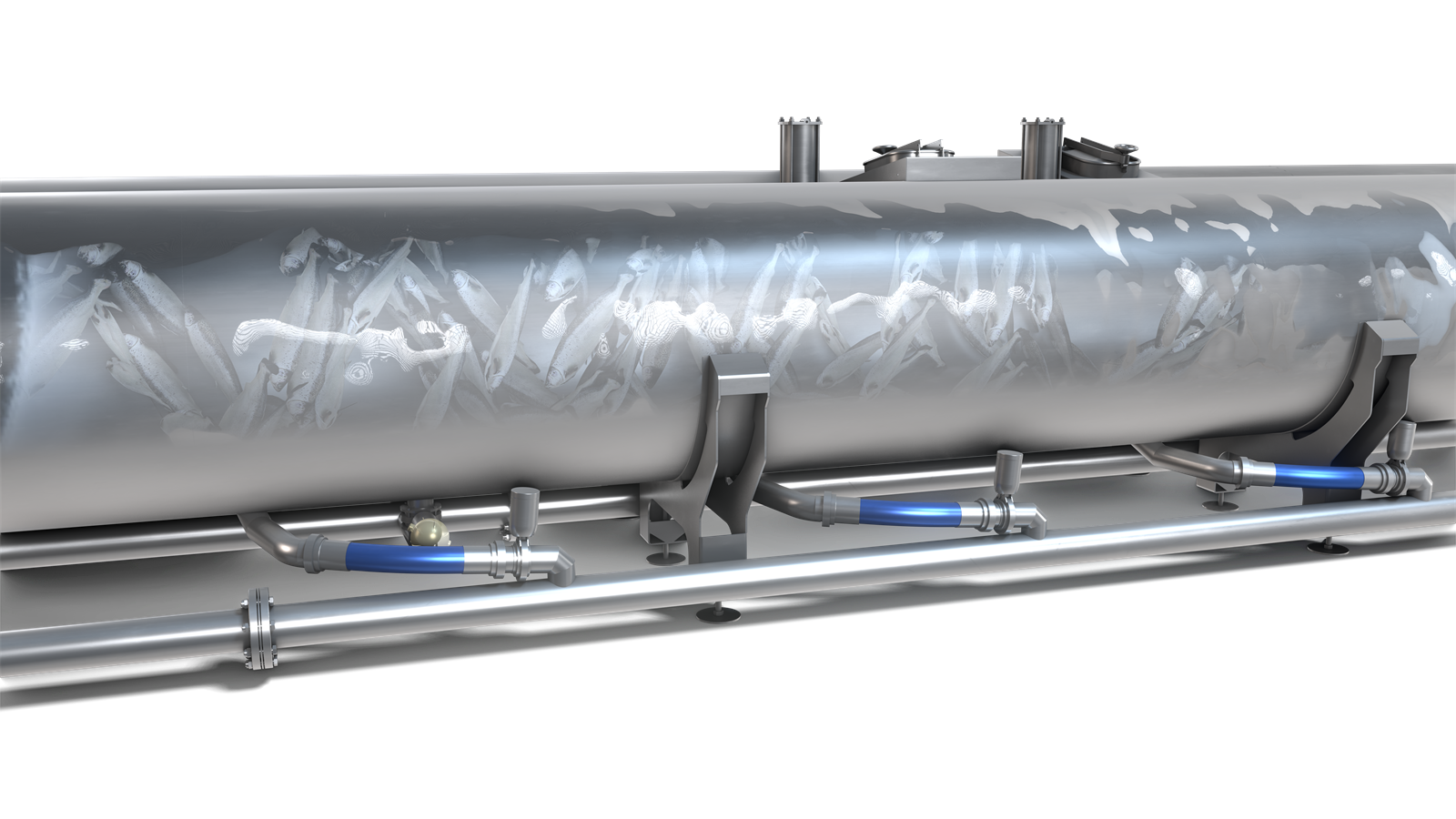

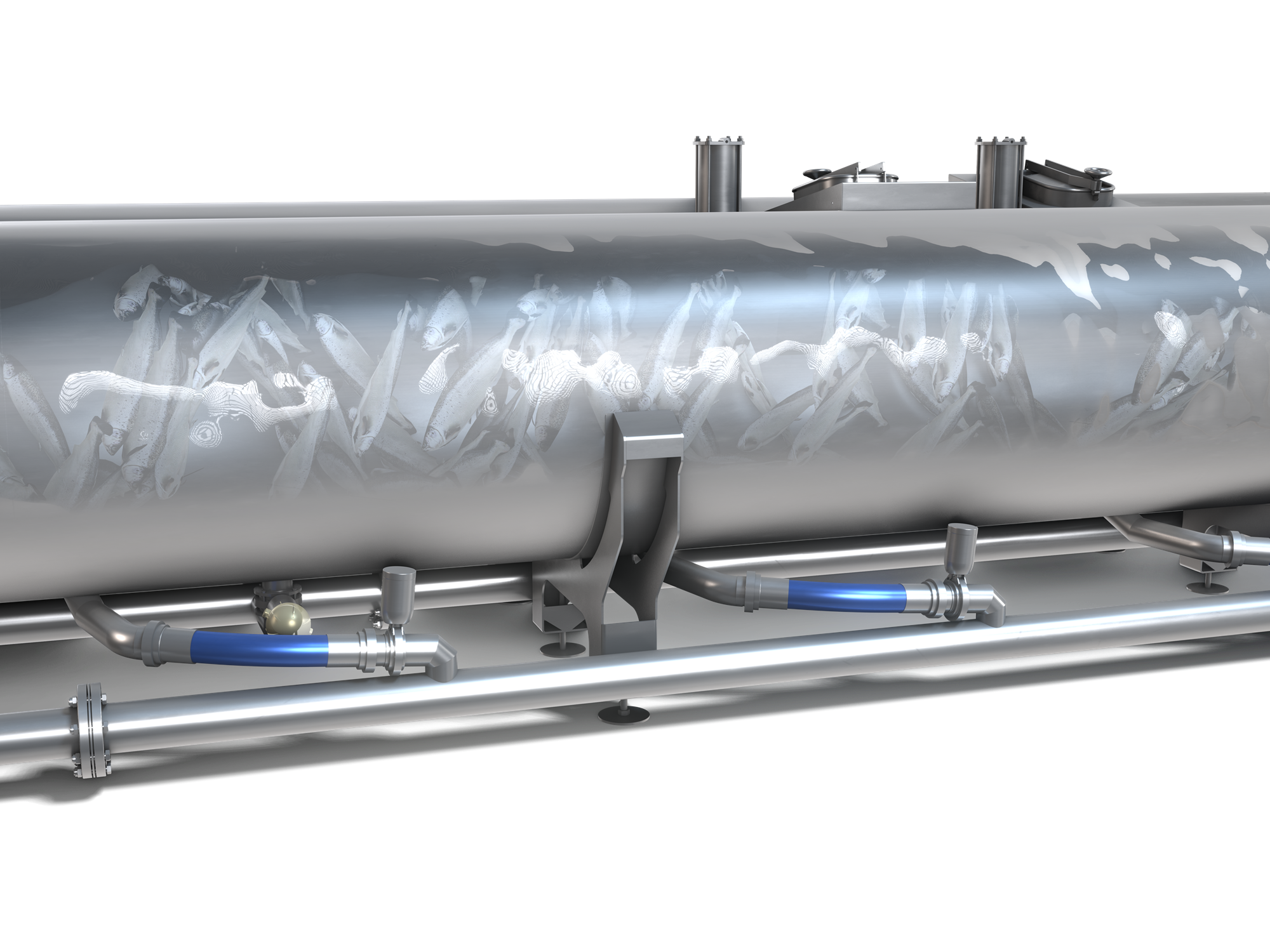

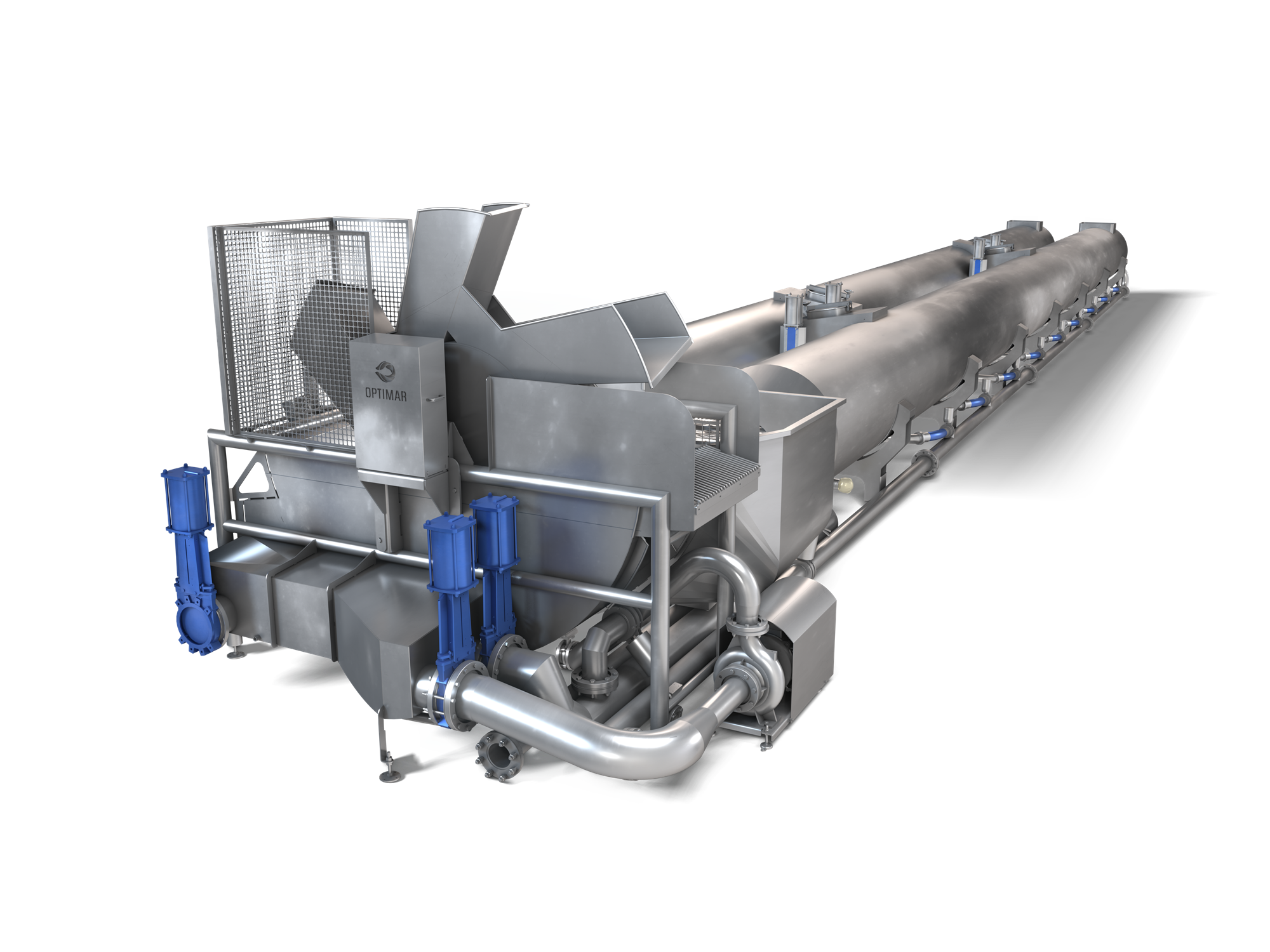

The Main tube is first filled with water from the supporting waterflow system. After and during filling, a pump is providing waterflow circulation from one end to the other. The Main tube is to be filled with fish up to 65% of the total volume, and the fish will then be conveyed by the waterflow to the outgoing end of the tube. Water is injected into the tube via a series of nozzles that creates a special water current that gently pushes the fish forward. At the outgoing end it is placed a drum wheel which is gently lifting the fish out of the tube. The waterflow can also be set to idle mode in order for the fish to be stored for a set period of time.

BENEFITS:

- Extremely flexible and built and operated for your needs.

- Can be placed both inside and outside.

- Dimensions from 10 to 100 cubic per pipe.

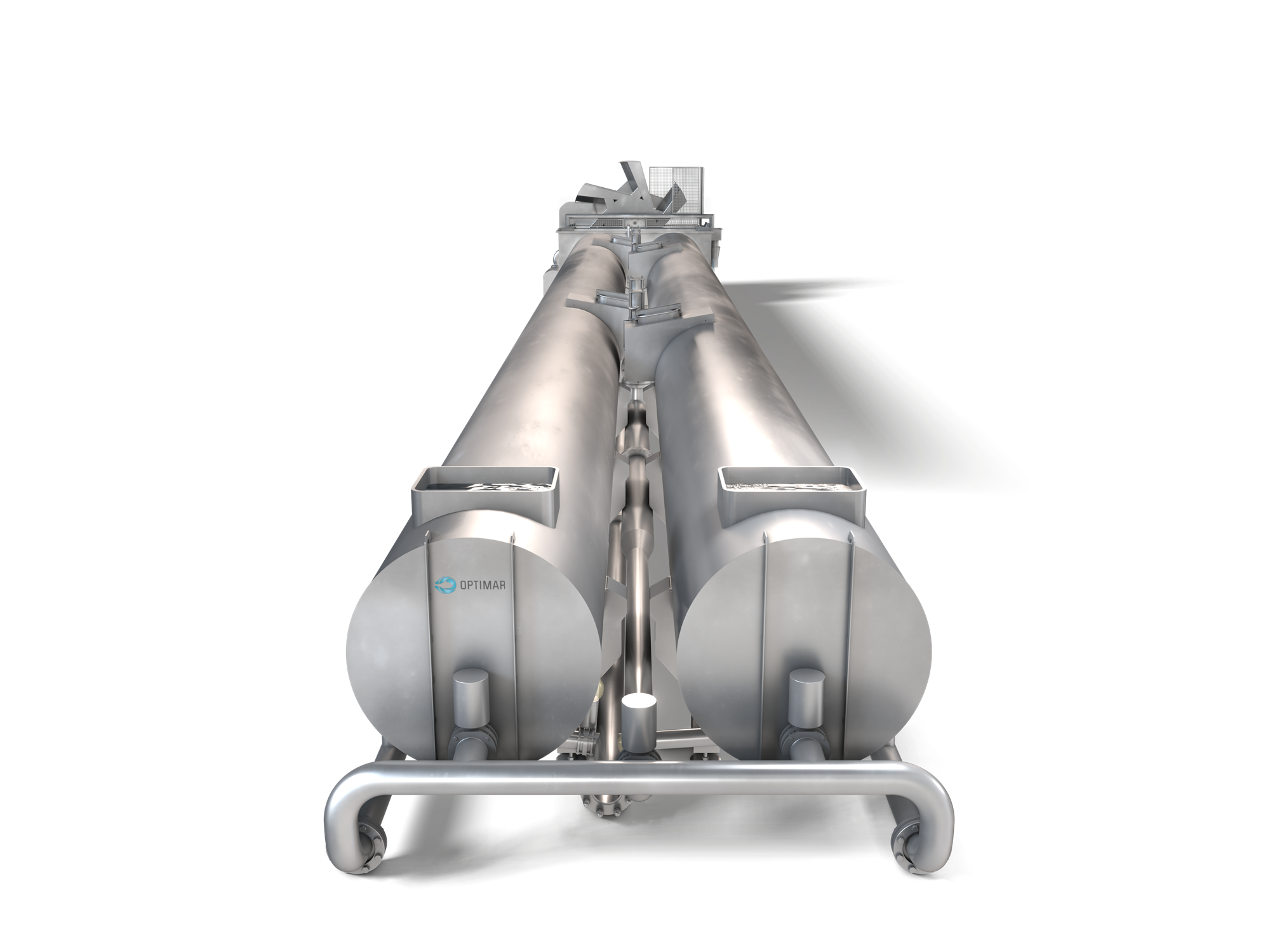

- Up to three pipes per outfeed unit, where each pipe can run in each their mode depending on the present need (chilling, storing, bleeding, washing).

- Capacity 70 tons per hour per outfeed unit. Scaled up outfeed units are also available.

- In example a 20m long DN1000 tube will have a holding capacity of 16 cubics. The same arrangement with a DN1200 tube will hold approx 23 cubics. Additionally the outfeed tank will represent an additional 8 cubics of hold ing capacity, whereof upto 65% of the volume can represent pure fish.

- Motion and cooling of the fish before and after gill cutting creates an efficient bleeding process.

- Storing and buffering during slaughtering.

- Flexible bleeding time.

- Helps you emptying the receiving area or boat efficiently during production.

- Helps preventing blood in the RSV tanks.

With Optitube there are almost no limits!

SPECIFICATIONS:

- Standard outfeed rate is maximum 1000kg fish per minute. Higher capacity available if requested.

- Diameter = (Ø1,0, Ø1,2m or Ø1,4).

- Length = up to 36 meters.

- Fish filling rate = up to 65%.

- Outfeed wheel = 8m3.

- Number of pipes = 1, 2 or 3.

- Bleeding time and capacity tailored to customer needs.

Included:

- Main tube and framework built in AISI304 Stainless Steel.

- Stainless steel Outfeed wheel for 1-3 tube(s) 8m3 capacity, hygienically designed for gently lifting out processed fish.

- Inlet valves at the start section of the tube, and for each 1,5m of the tube.

- Outlet valves included to control the fish flow towards specified positions to enable storing of fish within the pipe, or to increase the bleeding time.

- Circulation pump.

Optional:

- Valve for holding fish separated from the outfeed unit during storage.

- Optimar Commander Web and Commander On-site.

- Integration with RSW system for chilling and changing of water.

- Retractable washing nozzles for automatic cleaning inside of the tube (CIP).

- Washing nozzles for automatic cleaning outside of the tube.

- Stand alone Control Cabinet controlled by Omron PLC and Optimar Software. Specific parameters can be adjusted from a Omron HMI panel on the Cabinet.