HOW DOES IT WORK

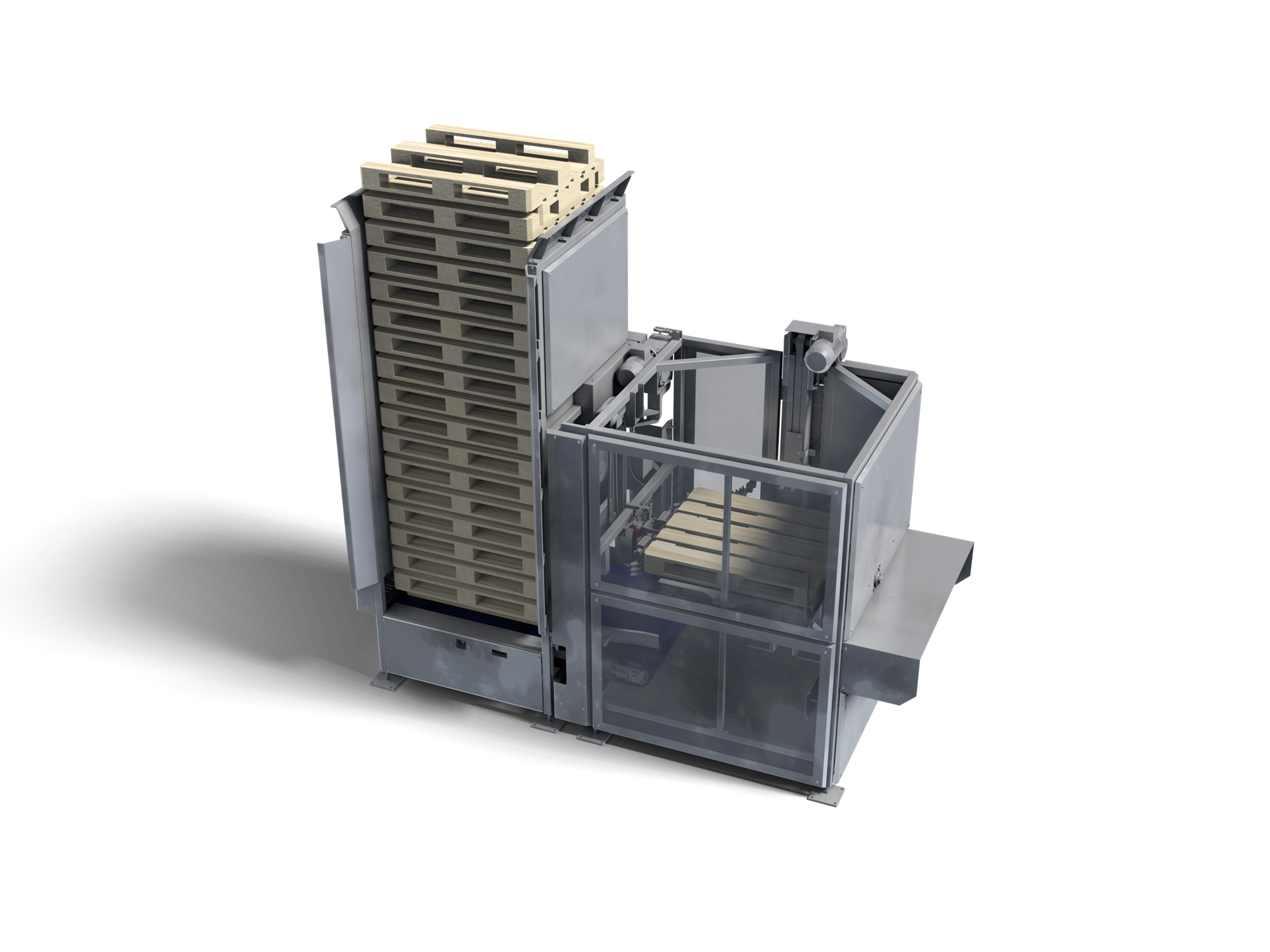

The Pallet Stack Splitter is a pallet magazine who is taking pallet stacks from an interconnected state (placed faced towards each other) to being delivered automatically one by one with the upside up. The process is done in two steps, where it first picks out two pallets, and next split these two into individuals.

BENEFITS

The system can be used on any factory where pallet stacks are delivered in a compact interconnected state. By purchasing pallet stacks like this and combine it with the Pallet Stack Splitter, transport costs and environmental impact may be reduced, without causing any extra labor at the plant where the pallet should be taken into use. Any plant that use automated palletizing for any purpose can have this equipment integrated at their facilities.

SPECIFICATIONS

- General parts are made of Stainless steel 304 or 316 or other corrosion resistant and cleanable materials.

- Size and footprint 3,8m x 1,9m x 3,7m (L x W x H).

- Weight 3,1 tons.

- Capacity 2 pallets per minute.

- Can be delivered for different pallet sizes (1180x980 is the standard configuration).

- Max stacking height of pallets is 2,8m (in standard configuration).

- Automatically operated with Touch Screen HMI.

- Air supply: Ca. 100Nl/min / 7bar / ISO 8573-1 class:3,4,4.

- Power Supply: 3x400VAC+PE ,50Hz, 6.0kW/1x 230VAC+PE, 50Hz, 1.0kW.