HOW DOES IT WORK

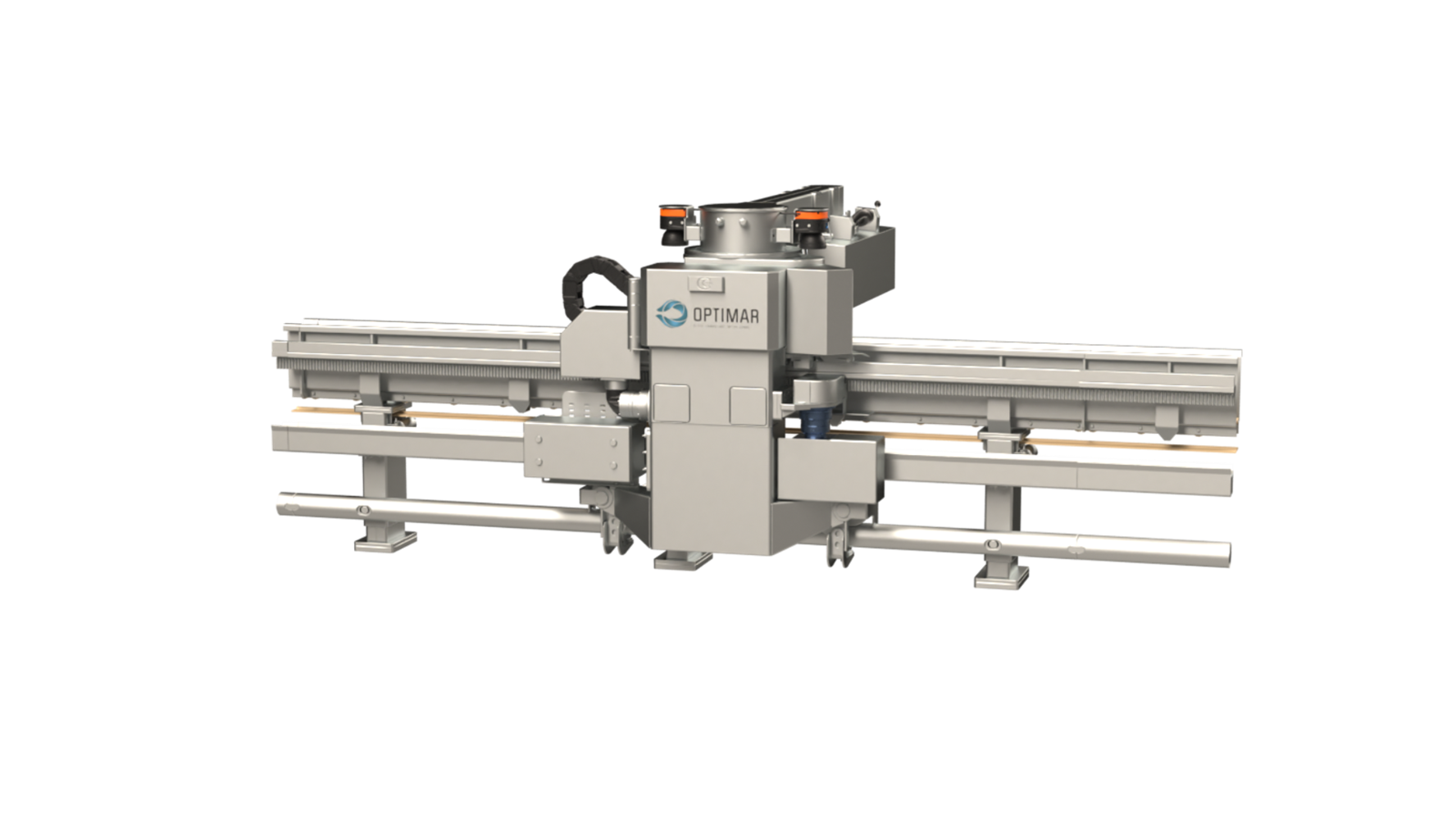

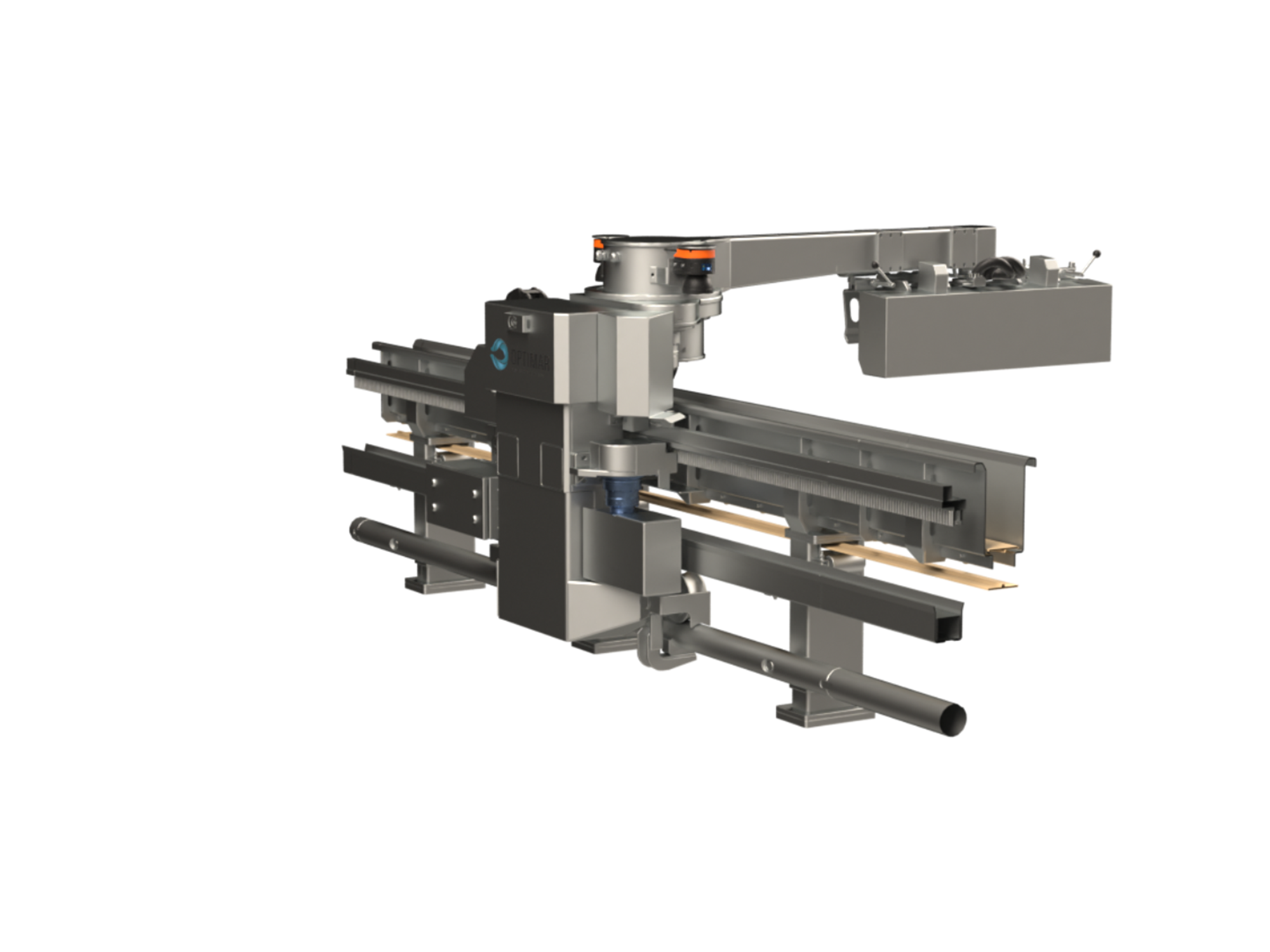

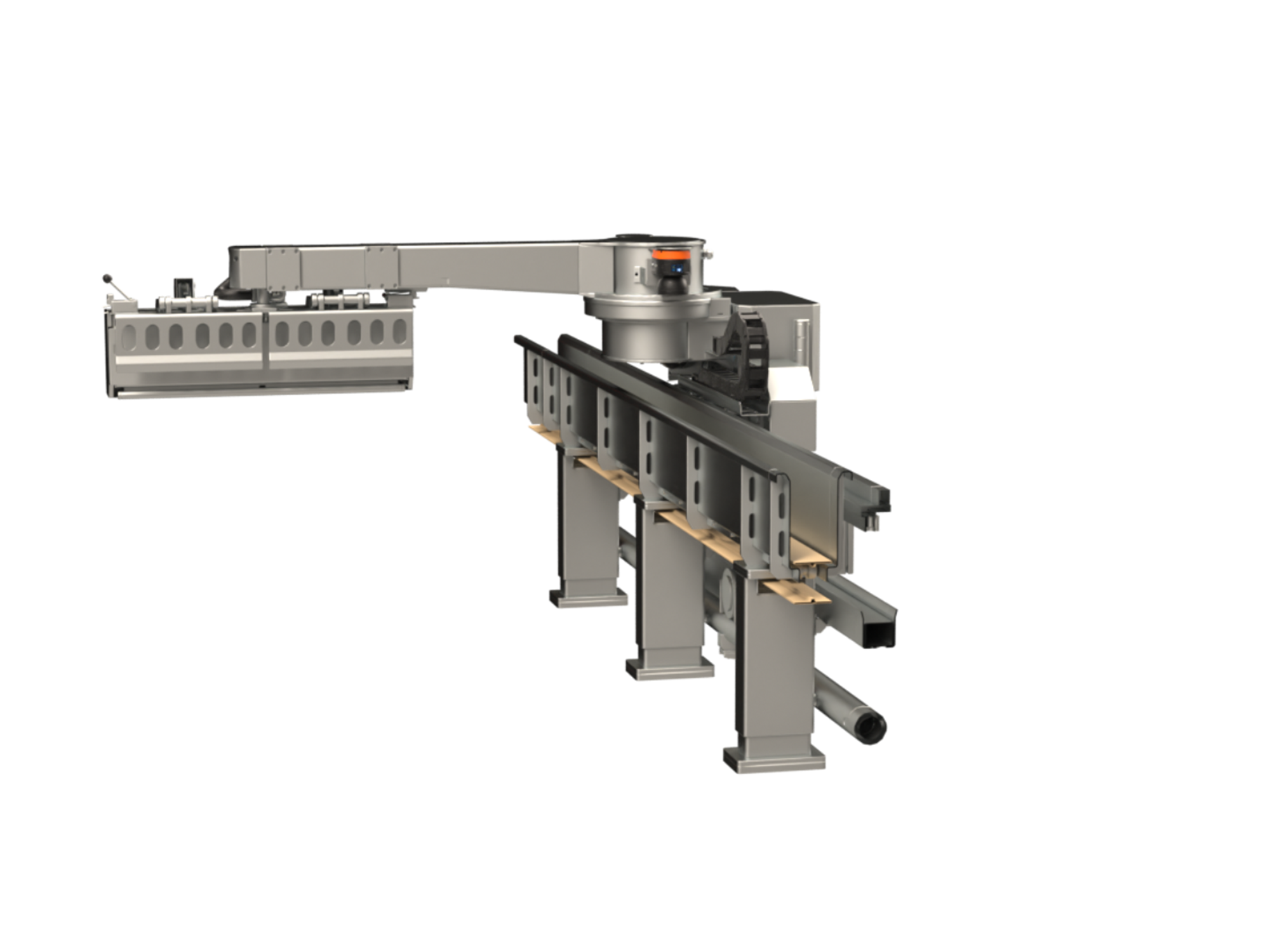

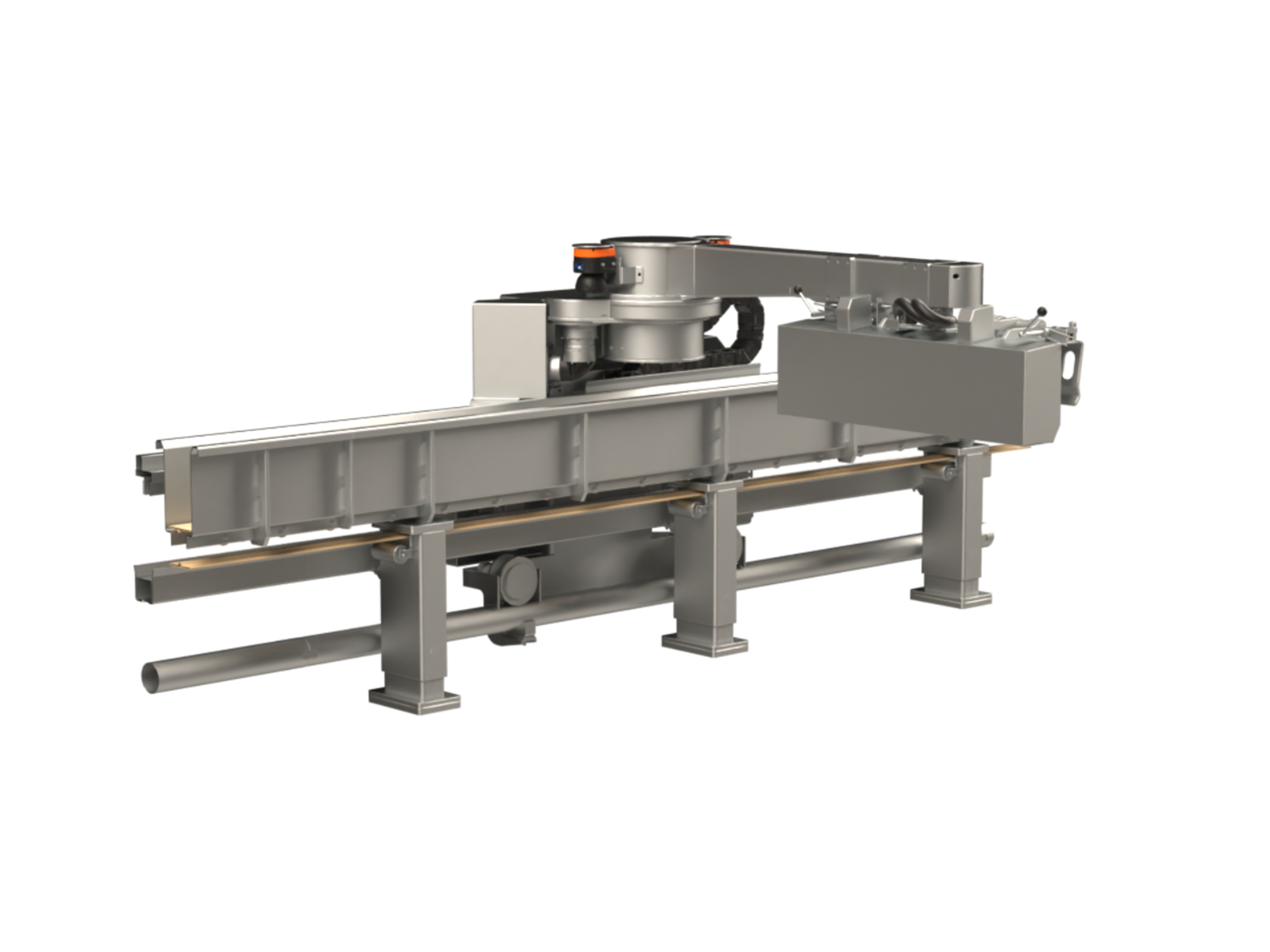

The V4 robotic system is specially designed to grip and lift frozen seafood blocks from vertical freezers in a gentle and foodsafe manner. The robot is is fixed against clean round rails alongside the outfeed conveyor, the same conveyor that is used to take away the blocks to packing. Moving automatically along the freezers, the robot picks up one whole block section at a time, and places the blocks on the OPTI v4 Conveyor. The V4 unloading system can be adapted to most customer needs, and to various setups, including setups with multiple robots.

BENEFITS

- Robust Stainless Steel Design

- One Robot can empty several freezers and on both sides

- Can be placed in existing walkway between freezers.

- The design is clean and easy to wash and maintain.

- No hidden areas underneath or above the product

- Works together with manual emptying of freezers, using the same method as human personnel.

- Can be used for any frozen product, for both full and half blocks, both at sea and on land.

- Can be equipped with different type of grippers, including adjustable grippers and grippers that adapts to the shape of the product to ensure maximum grip while still being gentle to the product.

- Sensors and servo technology ensures no harmful crashes of the equipment.

MAIN SPESIFICATIONS AND OPTIONS

- Capacity 3-6 blocks per minute

- Approx 2m radius, 360 degrees reach

- Unlimited lengthwise reach

- Corrosion resistant and >IP65 protected materials

- Standard blocks 100 or 150mm

- Servo gearmotors with feedback

- Automatic operation

- Operation interface with HMI panel and RF wireless control

- Ewon internet module for remote diagnostic is included

Block unload robot:

- 3x380-440 VAC, 50-60HZ, 4,0k

- 1x230 VAC, 60HZ, 2,2kW

- Air: 6 bar 10 l/min

OPTI V4 Conveyor:

- 230/400V AC, 4P, 1.5 KW