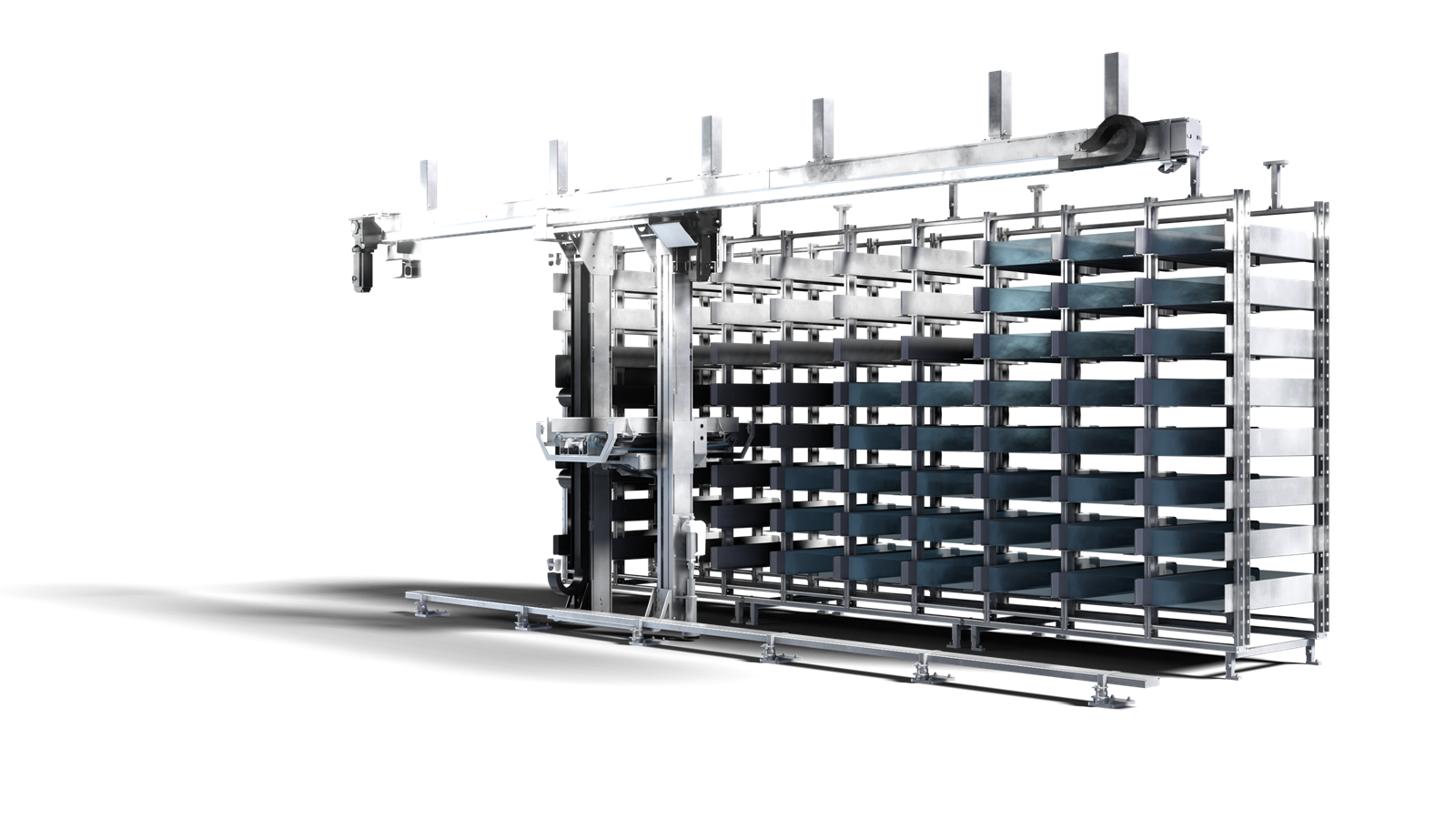

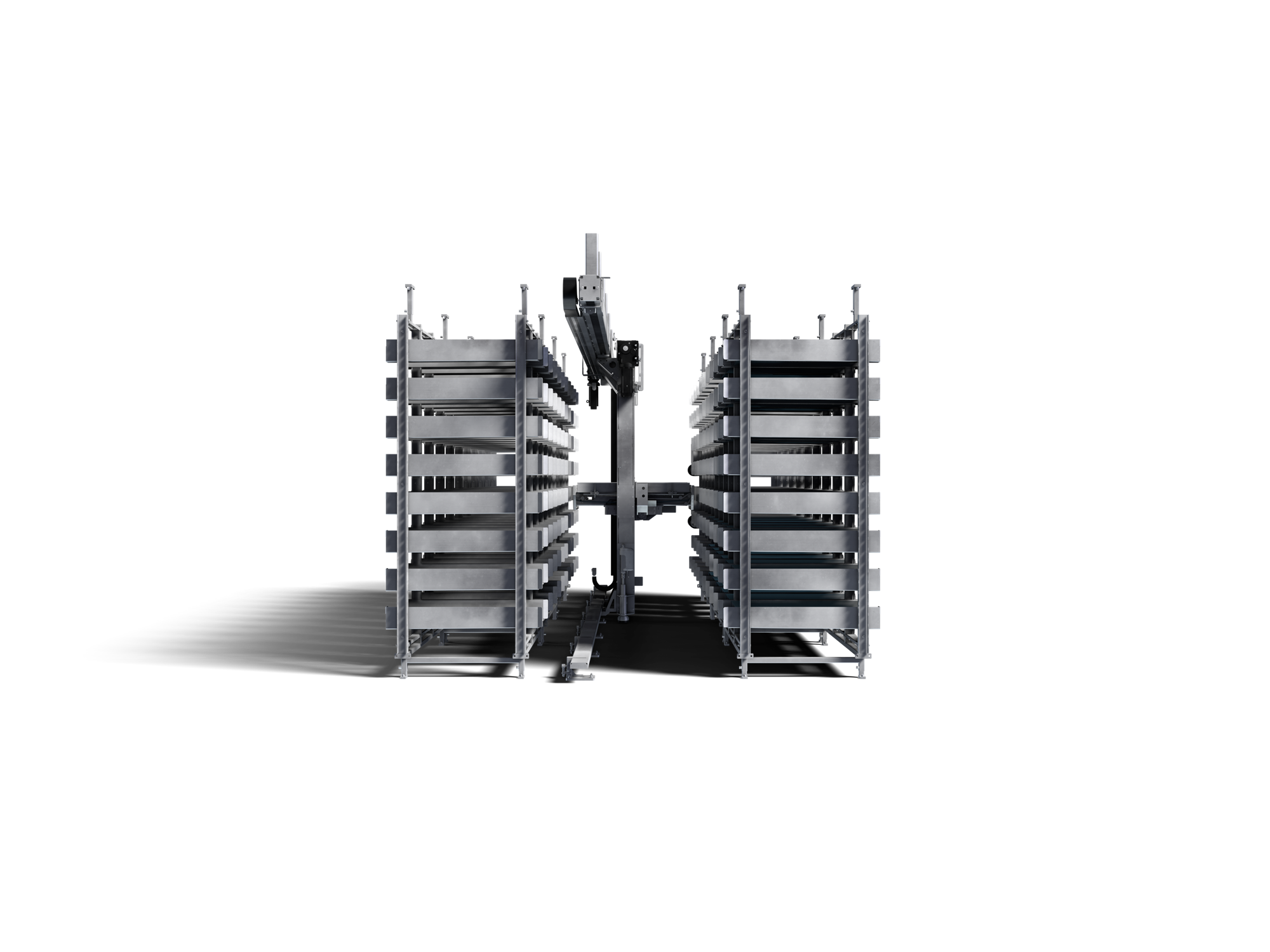

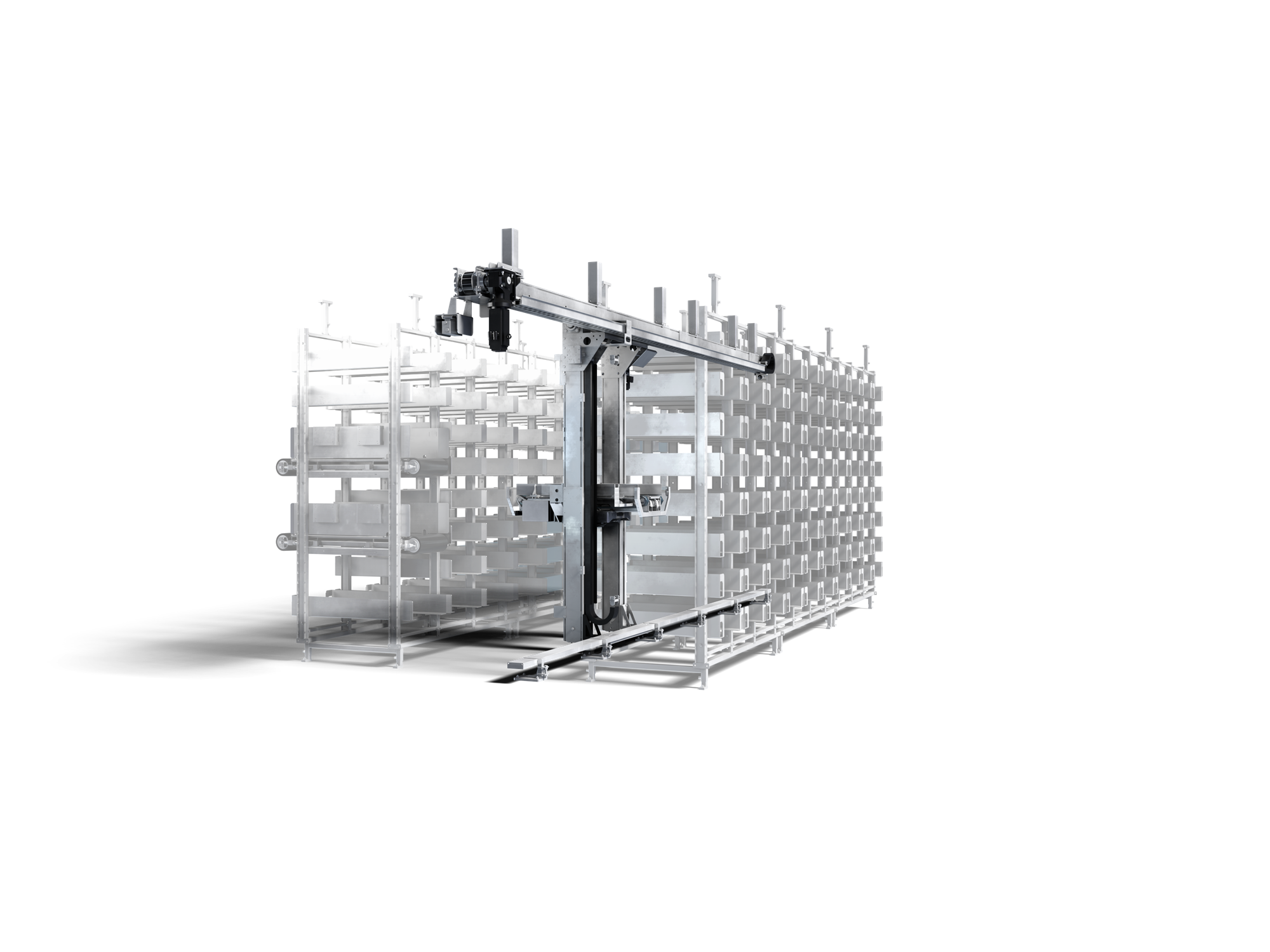

As they are entering the system, a hatch opens and a XY-axed servodriven elevator unit will pick up the product and run it to a suitable spot for temporary storing. Next and in between the XY-elevators may provide finished sortings for palletizing, as soon as there is enough for a full pallet. It can run infeed simultaneously with direct palletizing ongoing in parallel, so that all goods types except one goes to the hotel. This gives a total factory palletizing capacity higher than that of the hotel receive rate. At all time you have a full overview via HMI screens of the present contents in the hotel, and you can make signal whenever you want to run a new pallet and of which sort you want. You can create specific mixed pallets based on your requested setup.

CAPACITY:

Capacity depends on the following factors: Length and height of freezing room, number of products on shelf, and number of infeed. Example: Room: 8m length, 2,95m height, 4 master cartons on shelf and 1 infeed:

- Receive rate: >=2 cartons per. minute.

- Deliver rate: >= 8 cartons per. minute.

Higher capacity rates are available with the Optimar Z2 hotel system.

SPECIFICATIONS:

- All made from Stainless steel and/or other corrosion resisting materials.

- Omron Control System and HMI.

- Power Supply 3phase ,440V/60Hz, 15kW.

- Power Supply 1phase ,230V/60Hz, 2,2kW.

- Comp. Air 7 Bar, Approx.: 30Nl/min. ISO 8573-1 Class 3,3,4.