Stun & Bleed System

Fish processing in the most efficient and humane way possible

Increased efficiency, better fish welfare

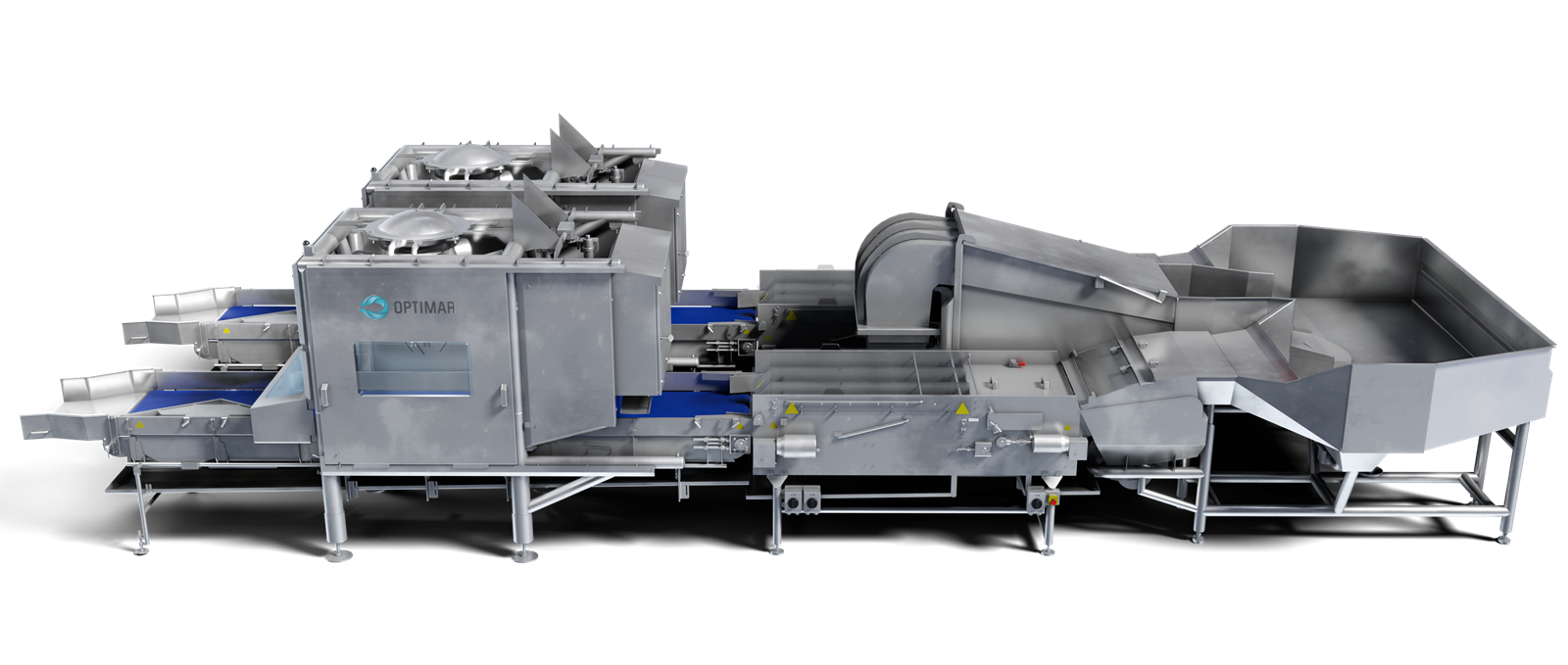

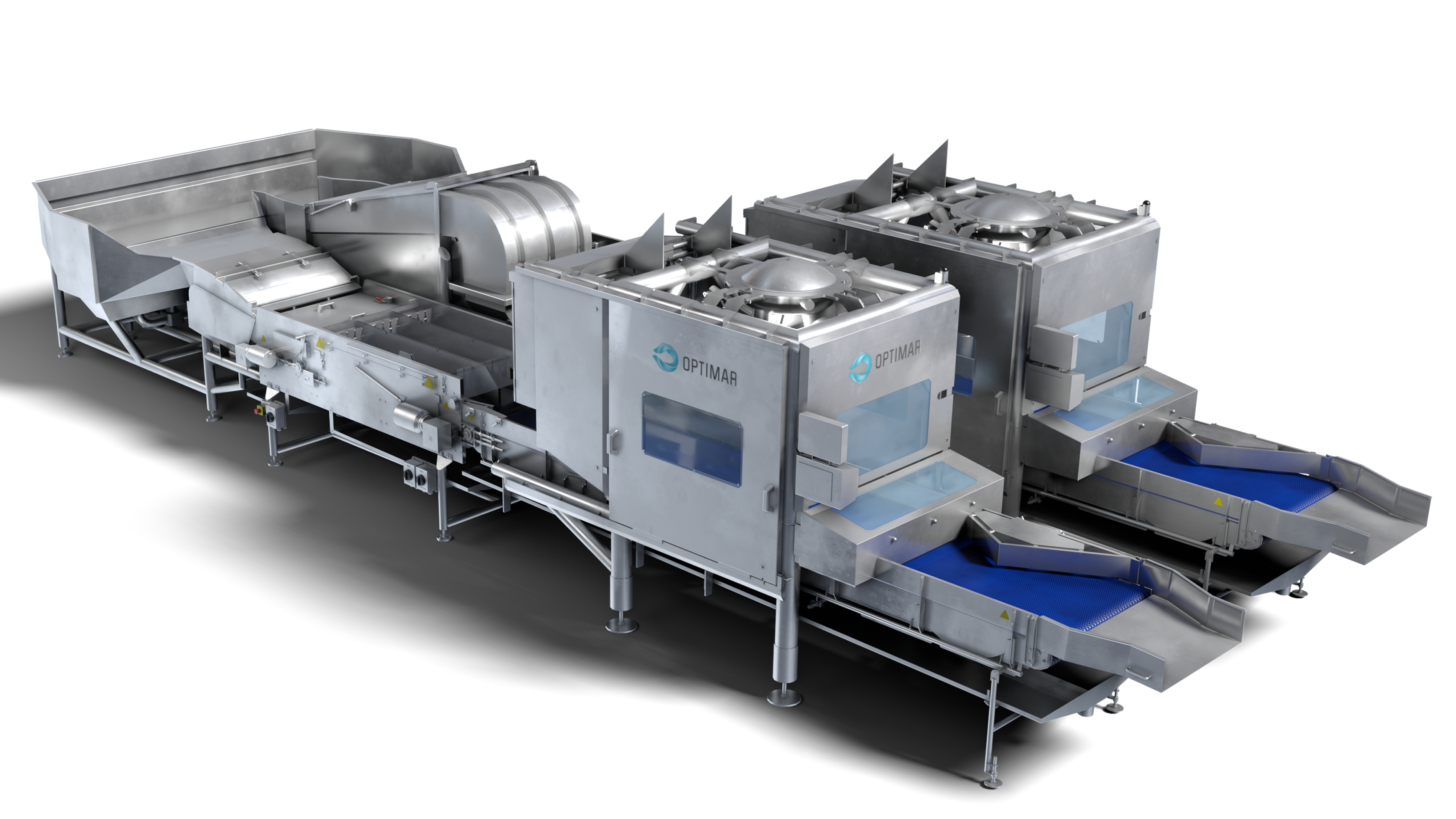

The Stun & Bleed system is taking care of the fish from the moment of entering alive and all the way until a humane killing is completed. The system is designed in order to increase the welfare of the animal, to allow for full automation, easy cleaning and to give access for easy surveillance of the process. Several options for handling different species and maximizing of the profit can be provided.

How does it work

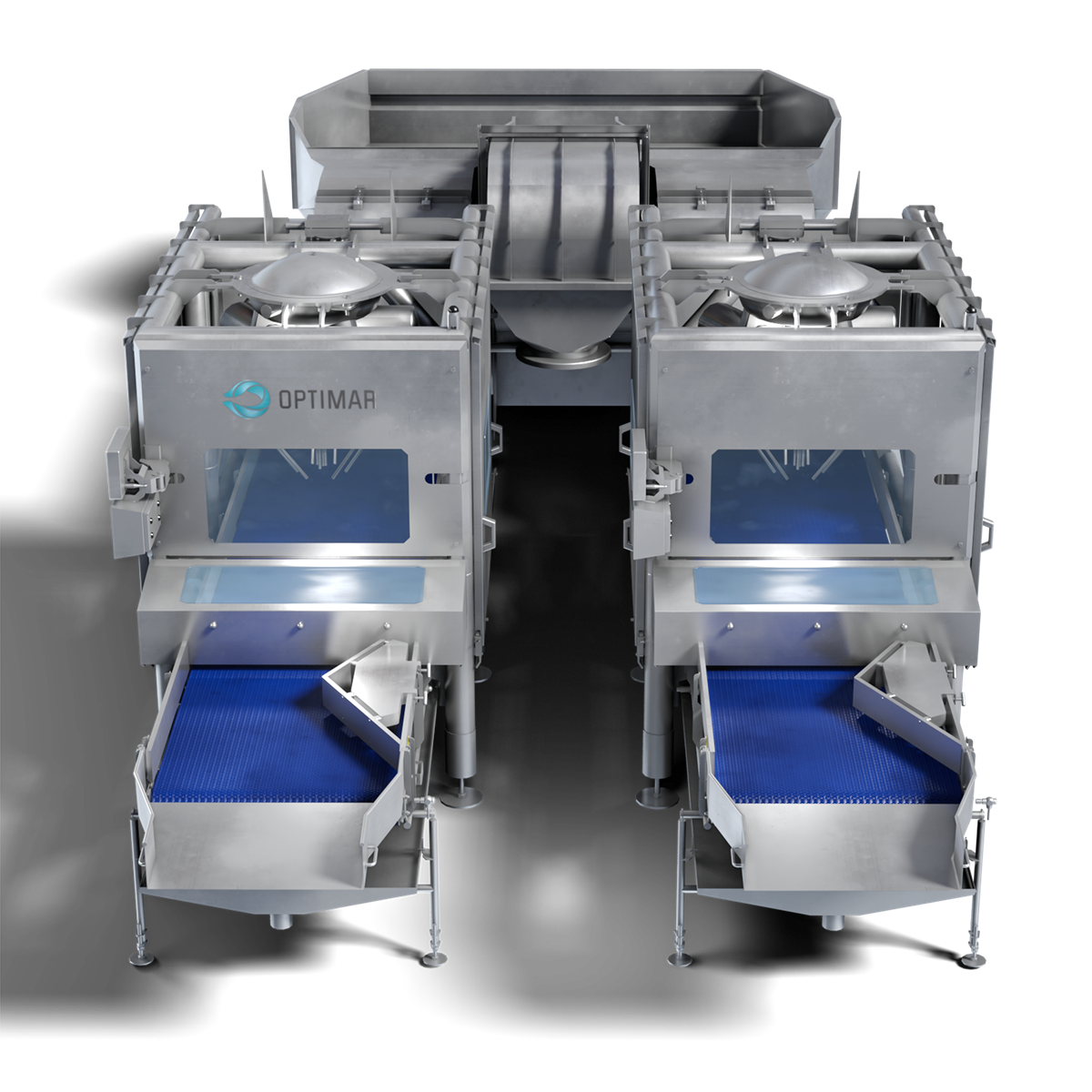

After the alive fish has been provided from any prior system, it slides over a dewatering chute that removes any excess water that was used for conveying it into the system. The fish goes into a Swim-in-unit filled with water, where it may move by own will and thus head first over to our electric stunner. The fish gets paralyzed and at the same time conveyed further towards the Gill Cutting Robot. Here it will receive a gill cut, in order for it to be killed and to allow the process of bleeding to start. In the end there is a control station where an operator can verify that all of the fish has been sufficiently killed as it is moved by an conveyor over to the next step in the process.

The stab position on the fish is decided by a computer vision system that is calculating where to position the cut based on training data and artificial intelligence.

The stab position on the fish is decided by a computer vision system that is calculating where to position the cut based on training data and artificial intelligence.

Benefits

The system can be used for Salmon or Trout as standard. If both species are selected, you can switch between the species just by the click of a button, and by optionally also changing the knife in order to make it perfectly fit for the size of the fish/specie. The system may also be provided for other species upon special request. In addition, the system can be provided with options for slowing down the inlet speed of the fish, for filtering the return water, for dispatching the cleaning fish before stunning, and to dispatch for this and other unwanted fish to go directly to an electric destruction stunner or to other means of killing. It is also optional to integrate an automatic counting of the fish that goes through, for automatic tracking of the success rate, and for weight estimation and for additional species. Optimar offers in addition to this system also both a preceding pump-in system for providing the fish to the Stun&Bleed, and also several kinds of follow-up systems to handle the bleeding of the fish and so forth.

The system typically handles 70 fish per minute per line, and no need of manual interventions is needed except the final inspection of the bypassing fish where it is ensured by man that the fish is sufficiently killed. At the start of the line, the Swim-in-unit is offered in several variants, and depending customer preferences it can be chosen whether this unit should provide fish for one or two lines of stunning and killing. To achieve even more capacity, additional lines may be provided.

The whole system can be integrated with Optimar Commander OnSite, as an overall factory SCADA system for monitoring and control. Other suppliers’ systems and machines could also be integrated for better overview and control, having the entire factory available on one control platform. Commander Web enables tracking of data towards operations and generating reports, as some of the key features. Commander enables full overview of the process, both on the factory floor and from anywhere in the world.

The system typically handles 70 fish per minute per line, and no need of manual interventions is needed except the final inspection of the bypassing fish where it is ensured by man that the fish is sufficiently killed. At the start of the line, the Swim-in-unit is offered in several variants, and depending customer preferences it can be chosen whether this unit should provide fish for one or two lines of stunning and killing. To achieve even more capacity, additional lines may be provided.

The whole system can be integrated with Optimar Commander OnSite, as an overall factory SCADA system for monitoring and control. Other suppliers’ systems and machines could also be integrated for better overview and control, having the entire factory available on one control platform. Commander Web enables tracking of data towards operations and generating reports, as some of the key features. Commander enables full overview of the process, both on the factory floor and from anywhere in the world.

Properties

- All electrical and pneumatically driven.

- General parts are made of Stainless steel 304 or 316 or other corrosion resistant and cleanable materials.

- All parts of the system have a full wash-down design.

- Size and footprint are specially tailored according to customer needs. Typical length is approximately 11 meters.

- If new species are requested, it is necessary for us to consider the amount of training data required for the Computer Vision system to know the specific specie and its cutting position, and also to evaluate if the cutting mechanism must be tailored accordingly.

Download product sheet

Videos

Contact