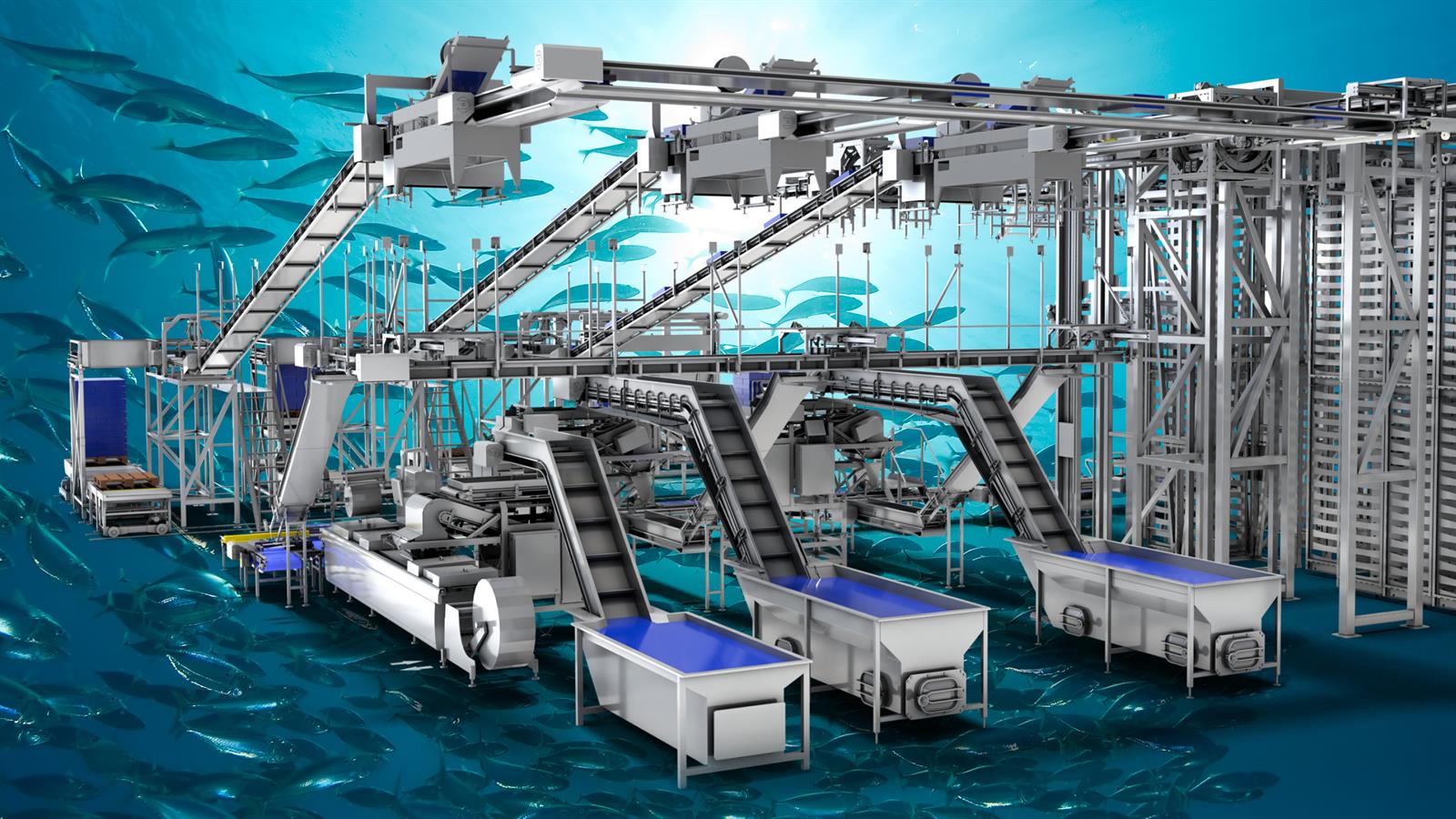

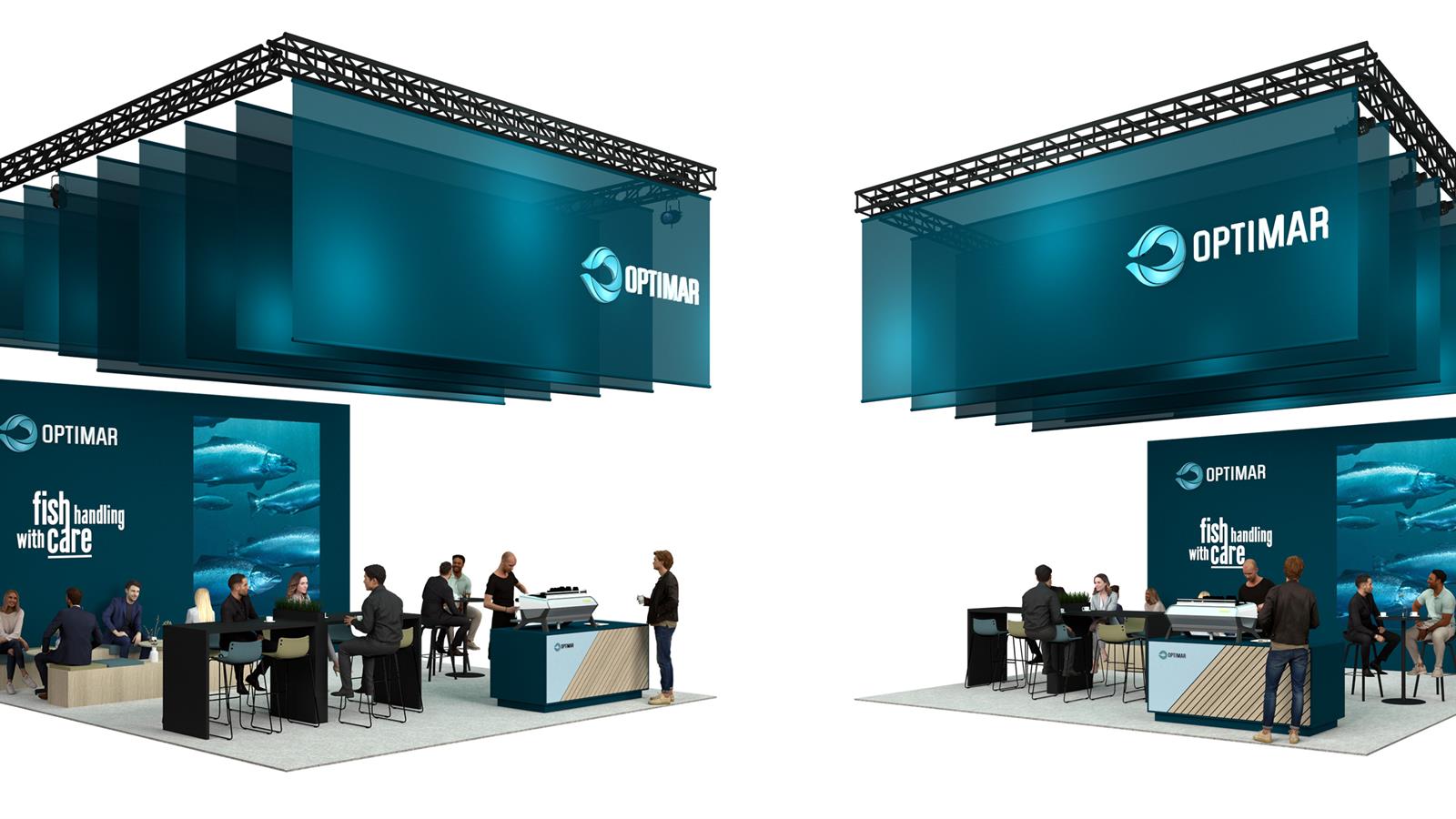

Seafood Expo Global is the world’s largest seafood trade event, bringing together leaders, suppliers, and innovators from around the world. Optimar will be there to show you how our solutions can improve your operations. Whether you're in fishing, aquaculture, or seafood processing, we have the expertise to help you succeed.

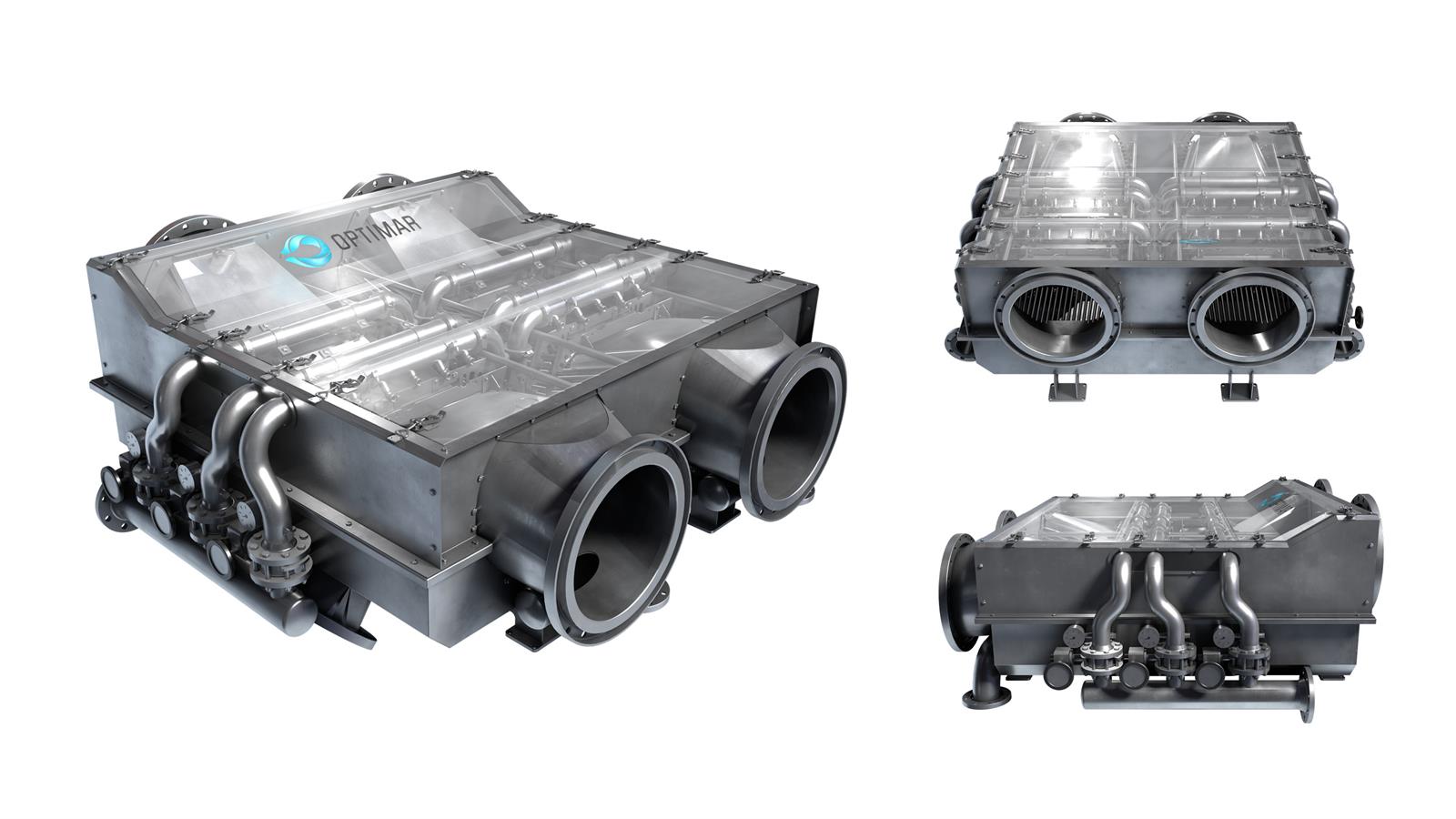

Optimar's Stun and Bleed Solution ensures humane stunning and precise gill cutting, reducing stress and optimizing bleeding to preserve fish quality and freshness. With advanced technology, it boosts efficiency while maintaining superior fish handling standards.

Optimar and Slippurinn Akureyeri are strengthening their collaboration with a strategic partnership to enhance their position in both domestic and international markets. This alliance will create new opportunities for both companies and their customers.

Team Optimar is happy to participate in the North Atlantic Seafood Forum 2025 in Bergen! Three of our experts will take the stage to share insights on innovative solutions, industry trends, and responsible resource management that drive the future of seafood processing.

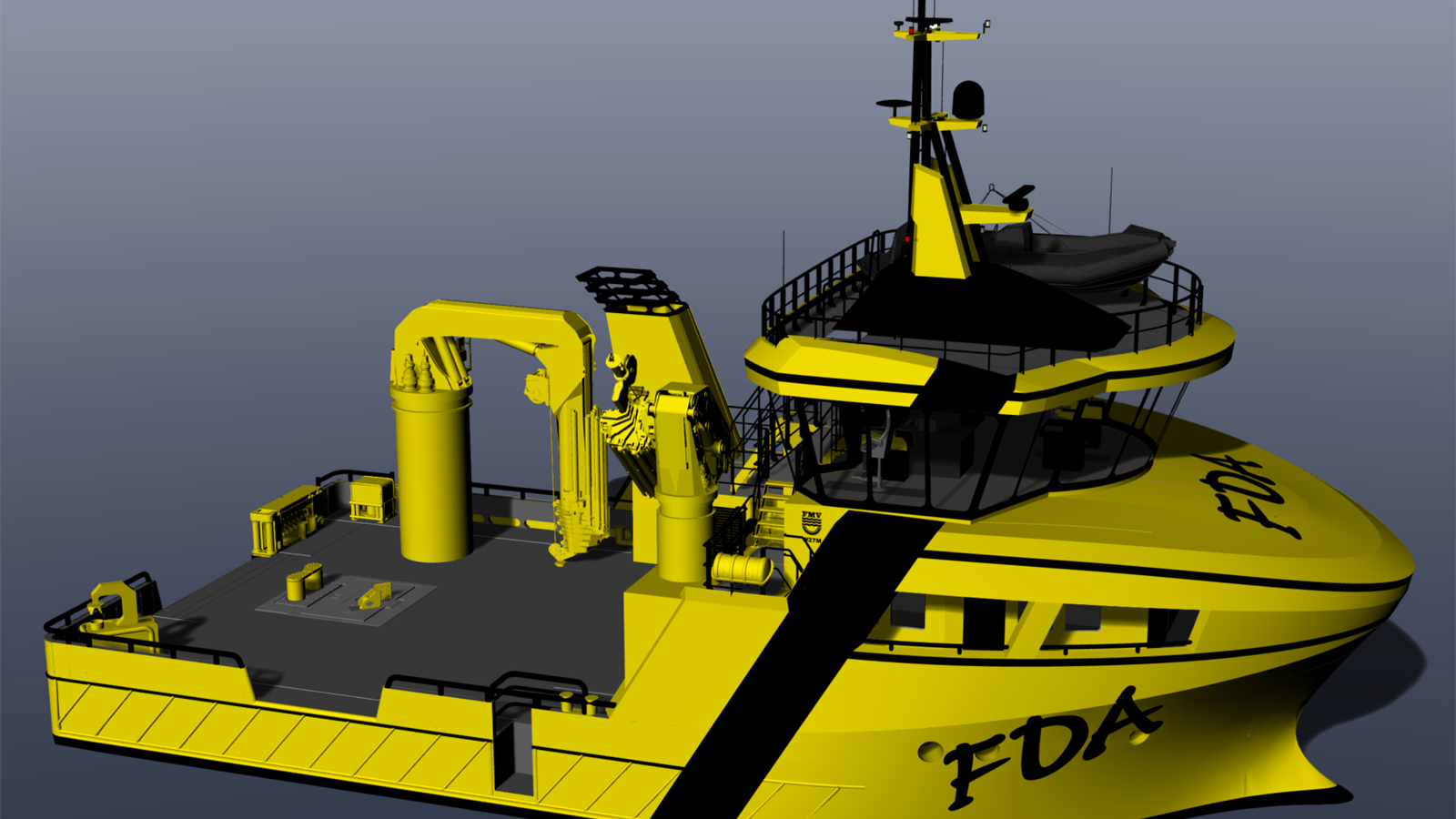

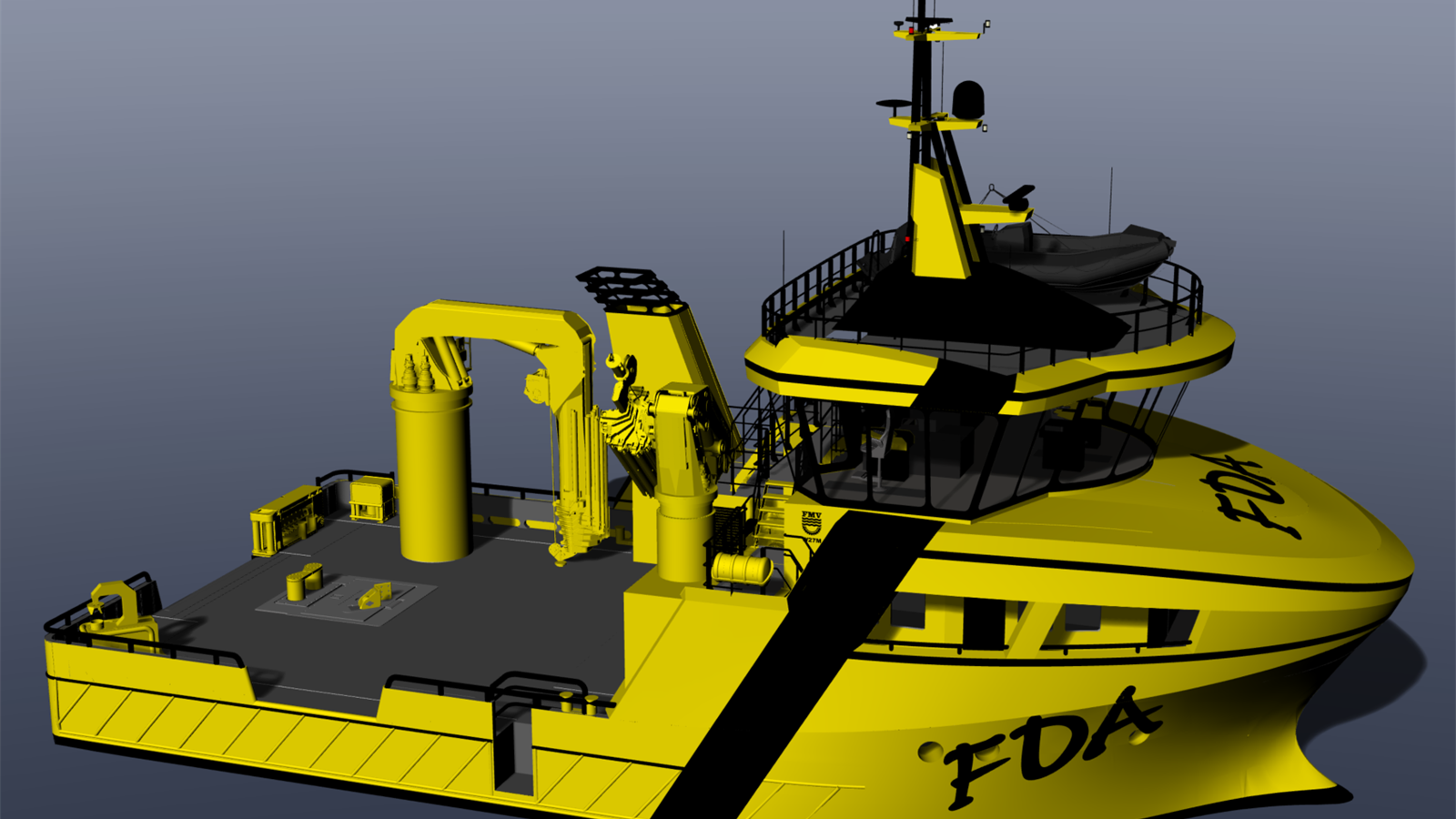

Servicebåten til Finnsnes Dykk & Anleggservice er for tiden er under bygging hos Fitjar Mekaniske Verksted. Den skal leveres i august. Fartøyet utrustes med bløggeanlegg fra Optimar, melder selskapet i en pressemelding. Båten er utstyrt med to fisketanker på til sammen 115 kubikk.

The service boat for Finnsnes Dykk & Anleggservice is currently under construction at Fitjar Mekaniske Verksted and is scheduled for delivery in August. The vessel will be equipped with a bleeding system from Optimar, according to a company press release. It features two fish tanks with a combined capacity of 115 cubic meters.

Müşteriler, çevre ve pazar genelinde balık ve kabukluların en etkili ve insancıl şekilde işlenmesi ve kesilmesine dair net beklentiler var. Tüm bu gereksinimleri ve beklentileri karşılamanıza yardımcı olacağız.

There are clear expectations from customers, the environment, and the market in general - to handle and slaughter both fish and crustaceans in the most effective and humane way possible. We will help you to meet all these requirements and expectations.

As of 2025, the Aquaculture Stewardship Council (ASC) is enforcing new standards for humane electrical stunning in fish slaughtering. This shift is crucial for producers looking to maintain ASC certification and meet consumer demand for ethically sourced seafood.

In the world of fisheries, where every minute counts and every operation is critical, having a reliable partner by your side can make all the difference. At Optimar, we are always ready to help, 24/7. No matter how big or small your problem or need is, we are here to solve it for you.

Jannicke Valderhaug has transitioned from Marketing Manager to Chief Commercial Officer (CCO) at Optimar, bringing years of experience and industry passion to the role. She looks forward to supporting Optimar’s sales team and driving growth.

This past year has been all about working shoulder-by-shoulder with our customers, tackling challenges to make everyday operations smoother. Before entering the new year, we’re more ready than ever to set the standard for responsible seafood processing.

Optimar Electric Stunner ensures humane slaughtering of all fish and crustaceans trough the slaughtering process. Our commitment to humane handling is tied to our dedication of producing a final product of high quality.

Det er som kjent flere utfordringer med lakselus for næringen. Det optimale er å få fjernet lusen uten bruk av kjemikalier eller medisiner. Det må også gjøres på en skånsom måte, for å unngå skader på fisken. Med nylig patent i Norge setter Optimar OptiFlush en ny standard innen fiskevelferd og bærekraftige avlusningsmetoder. Denne unike løsningen er utviklet for å møte de krevende behovene i oppdrettsnæringen på en skånsom og effektiv måte.

She has played a key role as Group Chief Accountant at Optimar since 2021. In other words, she brings valuable experience and engagement into her new leadership role. As CFO, she will further develop the company’s financial strategy to strengthen Optimar’s position.

Visit our stand 2MB12 at Conxemar, and see the Optimar Electric Stunner live - the most effective and humane way to stun all aquatic species. We will also be presenting other innovative and sustainable solutions for your factory, both onboard and onshore.

The project is an innovation competition under the Norwegian Directorate of Fisheries’ FangstID project. It challenges the industry to develop solutions for automatic catch registration and reporting on board the fishing vessels, as close to the fishing operation as possible. The project was launched in November 2022, and Optimar was announced as one of three companies advancing to the final phase.

The Optimar Electric Stunner ensures the welfare of fish and crustaceans throughout the slaughtering process. Our commitment to humane handling is tied to our dedication to producing a final product of high quality. By prioritizing the welfare of each animal, we embrace our ethical responsibility and support our customers in their daily work of farming and fishing.

In a significant milestone for the fishing industry, Optimar has successfully delivered and installed a state-of-the-art factory on board the freezing trawler "Berlin" for Deutsche Fischfang-Union (DFFU). The advanced factory is now fully operational, allowing the vessel to fish efficiently while ensuring 100% utilization of their catch.

Are you ready to transform your seafood business? Join us at Nor-Fishing, the industry's premier event, where we will showcase our cutting-edge solutions designed to enhance both the welfare of marine life and the efficiency of your operations.