As the world’s population grows, feeding everyone sustainably is becoming increasingly challenging. A dietary shift is necessary, with a greater emphasis on ocean-derived proteins. Technology plays a key role in this transition, and Optimar is at the forefront, delivering state-of-the-art equipment and solutions for sustainable, efficient and secure seafood production.

The signing of this exclusive agreement with OctoAqua strengthens their commitment to the Turkish aquaculture market.

At Optimar, our commitment extends far beyond providing cutting-edge fish handling solutions and processing equipment. As part of the seafood business, we harvest large resources from the ocean and often see the effects of environmental pollution firsthand. We take our role as environmental stewards seriously.

With tailored systems from Optimar, the slaughter capacity at the facility will increase from 40,000 tons per year to an impressive 120,000 tons per year. This represents a significant boost and reflects the increasing demand for quality products in the seafood market.

Are you in the fishing industry, either with wild catch, farming of fish or crustaceans? Then you know that there are clear expectations from customers, the environment, and the market - to handle and slaughter both fish and crustaceans in the most humane way possible. Team Optimar can support you with our expertise of fish handling with care.

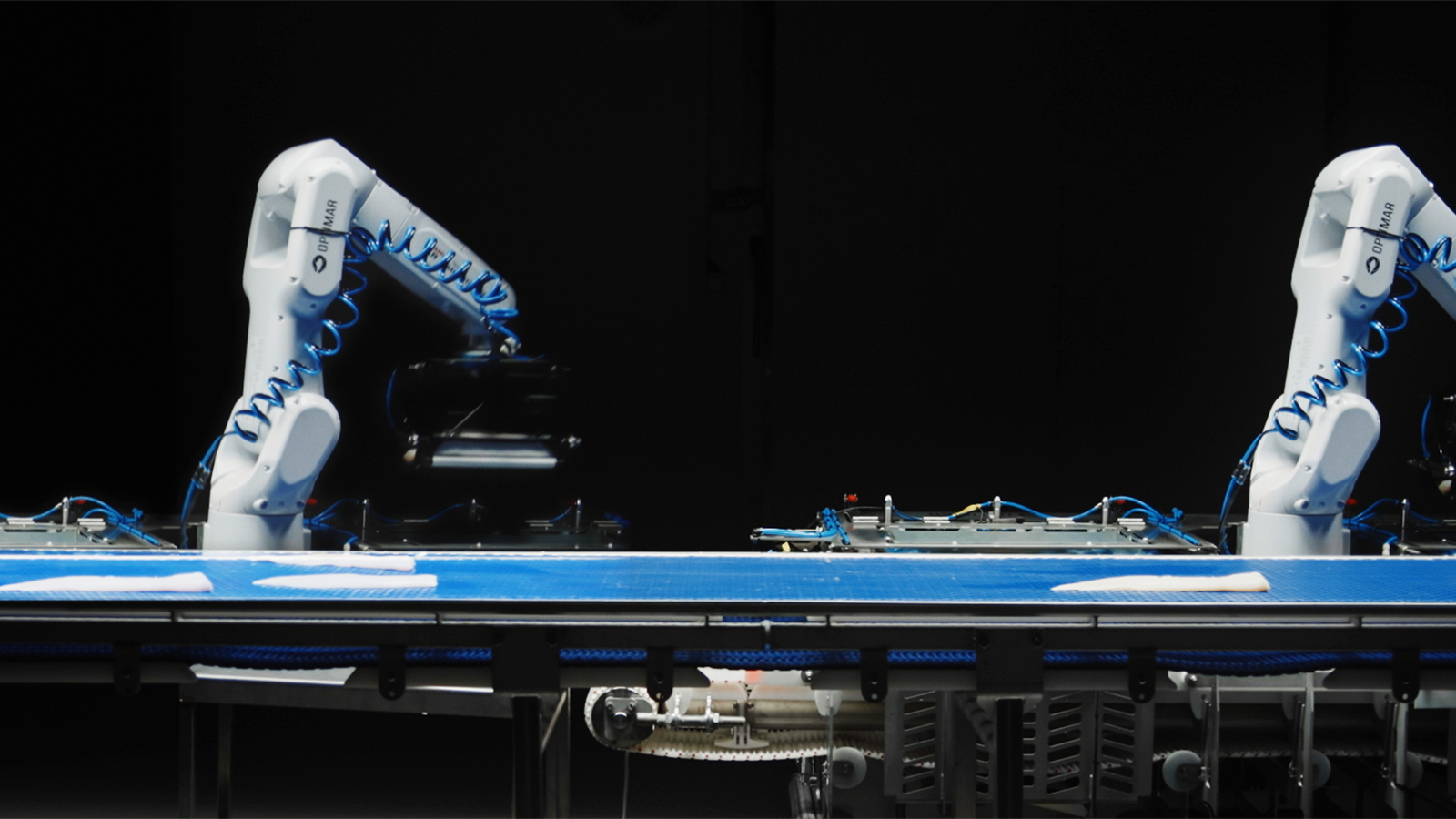

In the industry of fish processing facilities, seamless integration is the key to success. At Optimar, we specialize in bridging the gap between subsystems to create a cohesive and efficient operation. Let’s delve into what Optimar System Integrator is and how it can revolutionize your processing facility.

As of February 26, 2024, the Icelandic investor Kaldbakur has acquired Optimar International AS after negotiations with the company's former shareholders, the German investment firm Franz Haniel & Cie. GmbH, as well as Optimar AS management and employees. This acquisition marks a strategic move that will see Optimar continue to serve its global customers as an independent entity under Kaldbakur's portfolio.

In the ever-changing seascape of the fishing industry, Optimar stands at the forefront, steering towards a sustainable future. Recently showcased at Ombordfryst 2024, our Onboard segment takes center stage in addressing the challenges of decreasing fishing quotas and the pressing need for climate action.

In this season for reflection, our belief in the power of collective impact has never been stronger. On March 28th this year, Marks & Spencer and Optimar joined forces and Optimar hosted the very first Animal Welfare Week in our hometown Ålesund. Customers, partners, and research institutions from the global fishing industry came together to share insights and expertise on animal welfare. In Optimar we strive to make a difference through innovative solutions enabling more humane slaughter methods

Optimar announces Lene Christin Bratseth as Vice President for Sustainability and Business Development. She brings extensive experience from the fisheries and seafood industry, as well as economics and finance.

In the middle of the 90s, Optimar delivered the first edition of Olav E. Fiskerstrand’s pelagic factory. The company produces pelagic and whitefish of high quality on the West Coast of Norway and has done so for more than 100 years.

Aurora Fisheries, part of the Solander Group, has signed the contract for an 80-meter long and 15,4-meter wide factory trawler with delivery in the fourth quarter of 2025. Optimar is proud to be a part of this giant leap.

After 13 years, 300,000 pallets of fish have left M/S Nordborg. 19,000,000 fish blocks from capelin, herring, and mackerel have passed our packing machine since 2010.

Visit our stand 2MB12 at Conxemar, and see our Electric Stunner for shrimps - the most effective and humane way to stun. We will also be presenting other innovative and sustainable solutions for your factory, both onboard and onshore.

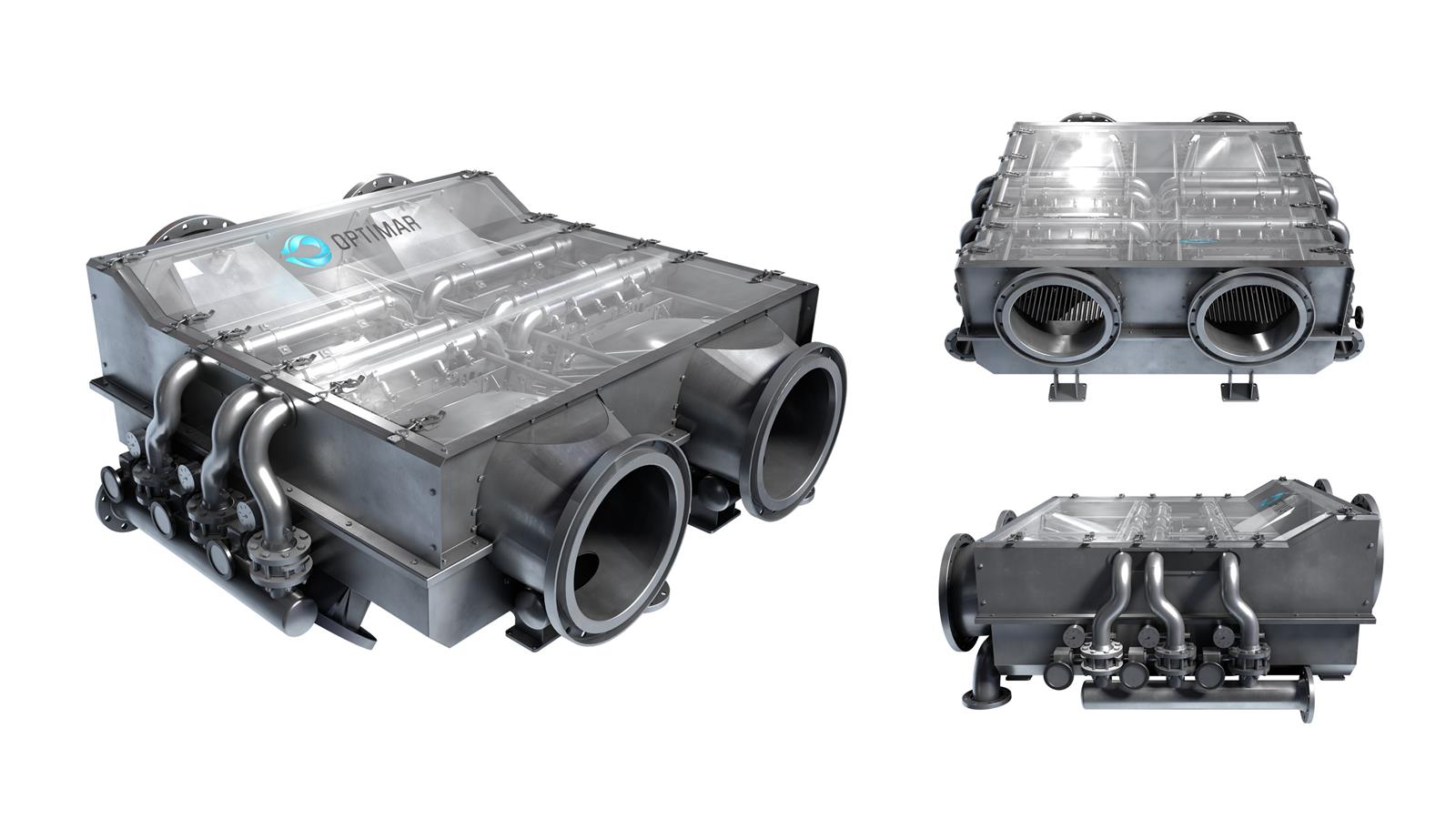

The Optimar electric stunner for shrimps is approved by the Norwegian government and will support farmers in their work on animal welfare for shrimps in their slaughtering prosess.

Smart solutions for efficient and sustainable fish farming. We deliver a great range of products to the aquaculture industry and have put together a short summary of some of our solutions. Some wich are developed in the last couple of years and some wich has been on the market for decades. Have a look and contact us if you need more information.

In our 2022 Sustainability Report, we take stock of our impact on the environment and explain how we are contributing to more sustainable seafood production – worldwide – for the benefit of both customers and consumers alike.

Attention, seafood enthusiasts and industry pioneers! Are you ready to take your seafood business to the next level? Then mark your calendars for Aqua Nor 2023, the ultimate gathering of the aquatic world's finest minds and innovations!

The FangstID program is an initiative from the Norwegian Directorate of Fisheries. The program aims to automate the registration of catches using new technology, provide more accurate catch data to the factories, ensure automatic quota reconciliation, and improve data for marine research. Now they have chosen Optimar as one of three companies for a crucial phase of the program - identifying relevant technology.

We continue to closely collaborate with our customers to develop the best methods for delousing. Our main focus is on fish welfare and safe operations, as well as helping our customers achieve higher efficiency and better quality.

.tmb-xl-16-9.jpeg?sfvrsn=fb86c4d0_1)

18ac9f318f8364e4a6b6ff000096f405.tmb-xl-16-9.png?sfvrsn=7f2ffbd0_1)