– We wanted an identical factory, but at the same time, we knew this was an opportunity to make some improvements. Our experience from the past four years has taught us a lot about how our operations flow, shipowner Sindre Johan Dyb explains.

Come to our stand at Seafood Expo Global in Barcelona, and see our Electric Stunner - the most effective and humane way to stun. We will also be presenting other innovative and sustainable solutions for your factory, both onboard and onshore.

As animal welfare have become increasingly important within the industry, we aim to lead the way in implementing practices that take these issues seriously. Our goal is to make a difference through our products and expertise, and we believe that there are many opportunities available for us to do so.

Come to our stand at Seafood Expo in Boston, and see our Electric Stunner - the most effective and humane way to stun. We will also be presenting other innovative and sustainable solutions for your factory, both onboard and onshore.

Myre Kystfisk will build the worlds first combined fishery- and stund and bleed vessel. With Optimar factory onboard, this will change how the fishing industry run their business.

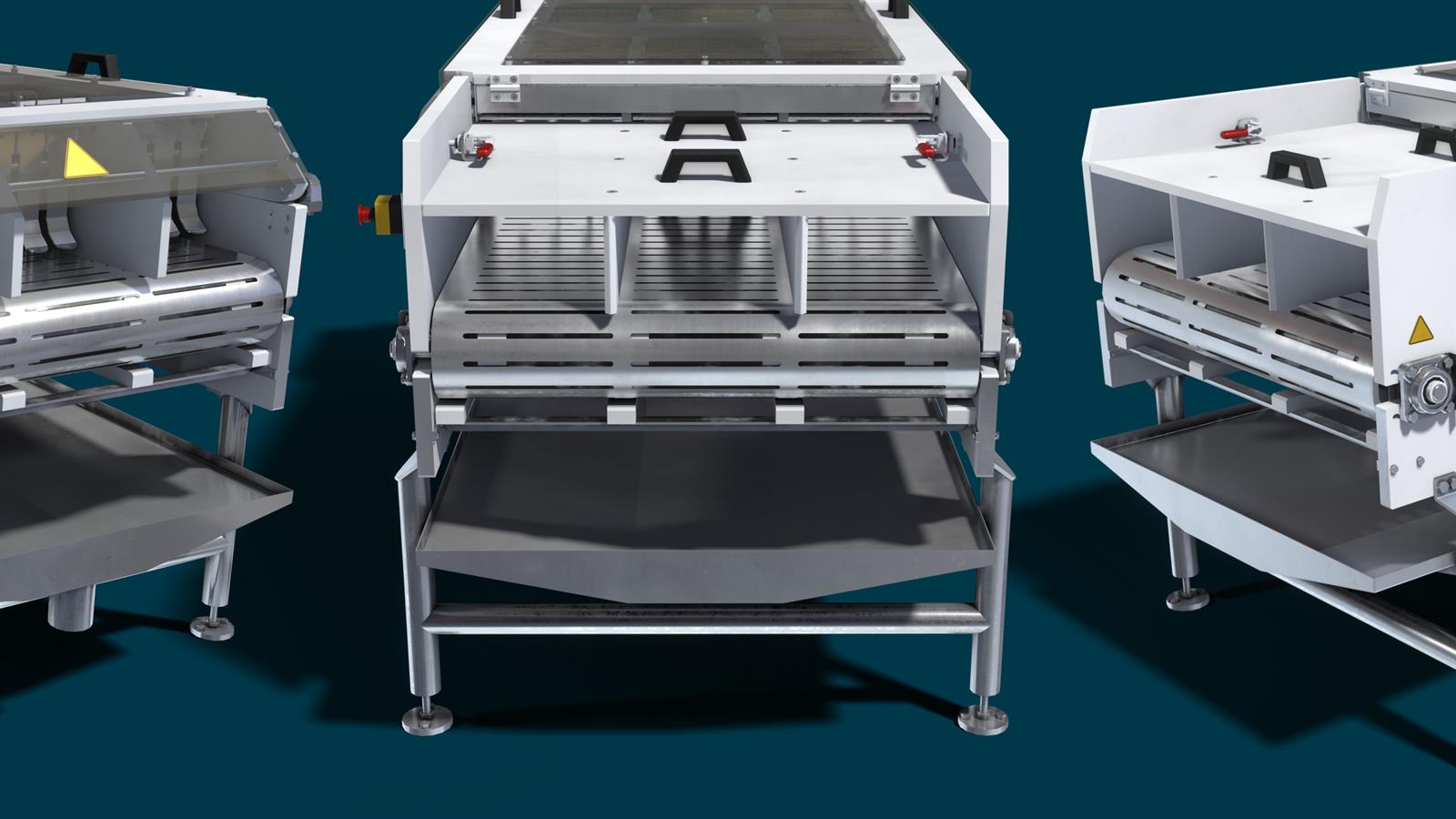

High quality seafood products are made from high quality fish handling. From the moment the fish is brought in, it is vital to secure its wellbeing. Optimar's automated systems maintain a high level of animal welfare as well as the saving of time, energy and money.

Another year has come to an end, and a new one is about to begin. It's time to reflect on the old one, before embracing the new. Looking back, we feel even more eager to create solutions taking better care of our shared planet and the species living here. Because this past year has truly reminded us that we are all connected.

Achieving a good flow in the factory is crucial to get the most out of a vessel’s capacity. With a higher degree of automation you will reduce the wear and tear on the crew as well. Retrofits from Optimar will uncover the adjustments necessary to realize just that.

Are you in the business of seafood farming? Then you know that there are clear expectations from customers, the environment, and the market in general - to handle and slaughter both fish and crustaceans in the most humane way possible.

All animals killed for food should be slaughtered humanely. This means that they must be effectively stunned, rendered instantaneously insensible, and remain unconsciousness until death supervenes.

We are ready! As the market situation changes, we want to be by your side to collaborate with these new challenges that demand more automatic systems that strengthen the safety of our customers. Hope to see you at Conxemar in Vigo, Spain - 4th, 5th and 6th October. Looking forward to good discussions and sharing our knowledge.

Earlier this year DFFU signed a contract with VARD, and now they have signed a contract with Optimar for delivery of a complete factory onboard, to be delivered in 2024. Optimar has a long history of delivering customized solutions for trawlers in the Barents. This is one of Optimar’s many areas of expertise, and to deliver this solution to DFFU is considered a declaration of trust.

When moving an industry forward, we need the large companies to take a stand. Optimar is proud to be the selected partner of Tesco when they focus on animal welfare in fish and shrimp farming among their suppliers.

Optimar continues to focus on our mission to more sustainable productions.

Da er du kanskje også opptatt av å skape høy verdi for kommende generasjoner, der 100% utnyttelse av råvarene spiller en viktig rolle. Fremtidens fiskeri krever høy grad av automasjon og robotisering, samt at digitaliseringen har en avgjørende rolle i forvaltningen av verdens marine ressurser. Meld deg på vårt studentarrangement for å høre oss dele våre erfaringer rundt dette!

Take a walk through the factory onboard Stornes in VR. When we use VR in close collaboration with our customers, we are able to detect bottle necks and possible challenges early in the engineering possess. Come and visit our stand to walk through different solutions onboard.

After over a year on sea the crew onboard Stornes has good experience in operating the processing factory onboard. Hear their description of the factory onboard.

Optimar’s new Sustainability Report shows how we are working as an organization to manage all our resources in a way that creates value not only today but for the generations to come.

As a systems integrator, we provide the time, talent, and technology required to turn your vision into reality – from initial plan to completed project. We can use our knowledge from both onboard, onshore, and fish farming - to create your best solution. Meet us at the Icelandic Fishery Expedition i June!

Over 30 years ago Optimar Spain was founded to fulfil a Norwegian contract at a local shipyard.

.tmb-xl-16-9.jpg?sfvrsn=78fdfad0_1)